Aseptic Areas

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Principles Of Good Manufacturing Practice

The operative is a potential source of microorganisms and it is imperative that steps are taken to prevent this contamination.

ASEPTIC AREAS

A) Additional Requirements

i) Clothing

The operative is a potential

source of microorganisms and

it is imperative that steps

are taken to prevent this contamination. The operative

must wear sterile protective headwear

totally enclosing hair and beard,

spectacles, powder-free rubber

or plastic gloves (often two pairs are worn), a non-fibre-shedding

facemask (to prevent the release

of droplets) and footwear. A suitable

garment is a one

or two-piece trouser suit. Fresh sterile

clothing should be provided each time

a person

enters an aseptic

area.

ii) Entry to aseptic areas

Entry to an aseptic

suite is usually

through a ‘black–grey– white’ changing

procedure (Figure 23.4),

where white represents the highest

level of cleanliness. Movement from ‘black’ to ‘white’ is via two changing rooms,

the ‘grey’ area also serving as an entry

to the cleanroom (Figure 23.4). There are several types

of entry system

in use. More details

may be found in Whyte

(2010).

iii)

Equipment and operation

Any articles entering the aseptic area should ideally

be sterilized, but may be disinfected. In order to achieve this, articles should be transferred via a double-ended sterilizer or hatch

(i.e. with a door

at each end).

If they are not

to be discharged directly to the aseptic

area, they should be (1) double-wrapped before

sterilization; (2) transferred immediately after sterilizing into a clean environment until required; (3) transferred from this clean environment via a double-doored hatch (where the outer

wrapping is removed) to the aseptic

area (where the inner wrapper is removed at the workbench). Hatches and sterilizers must be designed so that only

one door may be

opened at any one time.

Solutions manufactured in the cleanroom may be brought

into the aseptic

area through a sterile 0.22 μm membrane

filter.

Workbenches,

including laminar flow

units, and equipment, should

be disinfected immediately before and after each work session. Equipment must be of the simplest design possible for the operation

being performed. Aseptic manipulations must be carried out in the grade A air of a laminar

flow cabinet or isolator. Speed, accuracy and economy of movement are essential features

of good aseptic

technique. It is therefore essential that workers

are well trained

and motivated and familiar

with

the task in hand. Observation and microbiological monitoring of the operator and of the environment are very important. Under no circumstances must living microorganisms, including those used for vaccine preparation and

for biological monitoring be introduced into the

aseptic area.

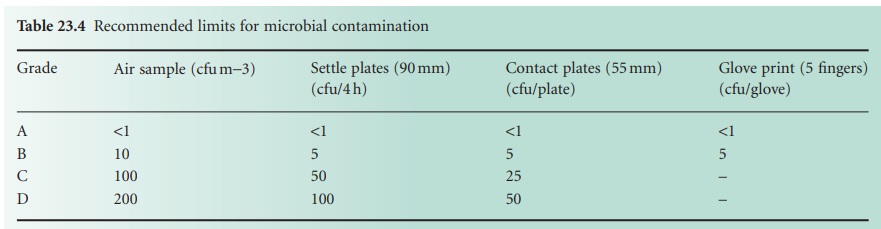

B) Environmental Monitoring

Monitoring of the environment is essential during

manufacturing. It ensures

that environmental requirements are being met and also helps spot trends.

Air is monitored for

particles and microorganisms.

Microorganisms are usually sought using settle plates

or active samplers, such as the slit-toagar sampler.

Settle plates rely on organisms falling from the atmosphere and

settling onto an exposed agar

plate. After a specified time (usually 4 hours) the plate will be

covered and incubated. A slit-to-agar sampler

draws in a specified volume of air, forcing organisms onto the surface of an agar plate.

This latter method

is able to give

a viable

count per volume,

but organisms may

be damaged and hence rendered

non-viable by the capture process. Limits of viable

counts for different

grades of air are

shown in Table 23.4. One of the

limitations of traditional microbial detection is the time

taken to culture

bacteria and fungi. There

is a great deal of interest in developing

rapid (Denyer, 2007) or instantaneous (Jiang, 2009) methods

of microbial detection.

The nature

of contamination can be informative. For example, the presence of Staphylococcus

spp. suggests human-borne contamination. The adequacy of changing facilities and gowning

would then be checked. In contrast, Bacillus

spores would suggest environmental contamination and the entry of equipment into the

cleanroom would be scrutinized.

Glove prints are taken by applying four

fingers and a thumb

to an agar plate. This ensures that disinfection of gloves is adequate. Surfaces

may be monitored by swapping or by using contact

plates. The latter

have the advantage of providing

a quantitative measure

of surface contamination,

but there is a risk of leaving

agar deposits on the surface

(Butson & Hawitt,

2008).

C) Eliminating Human Intervention

The greatest source of contamination in the cleanroom comes from the operating staff (Whyte & Hejab, 2007). Movement of staff can increase

particle shedding and disrupting laminar airflow.

It is not surprising, therefore, that modern practices seek to minimize

or even eliminate humans from the aseptic production area. This can be

achieved by the use of automation, of isolators and of

restricted access

barriers (RABs).

All aseptic

packaging should be carried out

in a grade A environment with

a grade B background (Table 23.2). Advances in technology now permit

the production of self-contained workstations, or isolators, which incorporate many of the design principles of cleanrooms

and laminar

flow cabinets.

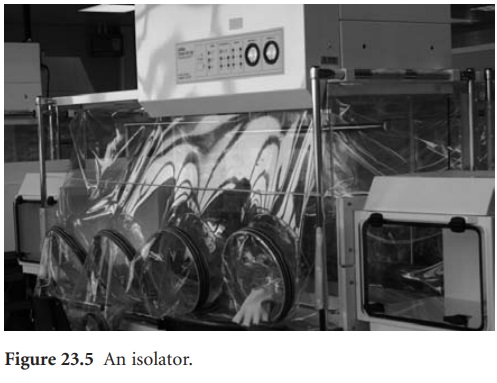

i) Isolators

The isolator both protects the product from contamination by the operator and the operator from any hazardous materials. Direct interaction between

the operator and the product is minimized by providing

a grade A laminar flow

of air with

a positive pressure, the internal space

being accessed by means of a glove/ sleeve system (Figure

23.5). A grade

D background is considered adequate for such

operations. A fuller

account of isolators

is given by Midcalf et al. (2004).

ii)

Restricted

access barrier systems

Restricted access

barrier systems (RABS) provide a level of control intermediate between an isolator

and a cleanroom (Agalloco & Akers, 2006).

They allow for easier

intervention than an isolator but require a grade B background.

iii)

Blow–fill–seal technology

Blow–fill–seal units

are purpose-built pieces of equipment which

carry out these

three steps in a continuous process within a controlled environment. Containers are formed from thermoplastic granules and blown

to form containers which

are then filled

and heat-sealed. These units are fitted with

a grade A air shower

and operated in a grade C environment for aseptic manufacture and a grade D background for products which

are to be terminally sterilized.

Related Topics