Classification or Size Separation

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Size, Reduction and Classification

In the introduction to this chapter, the influence of particle size on several processes was described.

CLASSIFICATION OR SIZE

SEPARATION

In

the introduction to this chapter, the influence of particle size on several

processes was described. The operation in which particles of a suitable size

are selected and others rejected because they are too small or too large is

called classification or size separation. This process is also important in

closed-circuit grinding, removal of fine powders to promote flow, and

restriction of particle size distribution to prevent segregation or to enhance

appearance.

Although

a number of particle properties can be used to classify a powder, only two are

important. The first is based on the ability of a particle to pass through an

aperture. This is sieving or screening. The second employs the drag forces on a

particle moving through a fluid. The term classification is sometimes

restricted to this method of separation, but in this text elutriation and

sedi-mentation will be used. In general, screening is applied to the separation

of coarse particles, and elutriation and sedimentation to fine particles.

Sieving and Screening

Sieves

and screens are widely used for the classification of relatively coarse

materials. For very large particles, greater than half an inch, a robust plate

perforated with holes is used. However, the pharmaceutical applications of

screening are with much smaller particles, and screens are in the form of woven

meshes. Unless special methods are used to prevent clogging and powder

aggregation, the lower useful limit resides in a cloth woven with 7900

meshes/m.

This

corresponds to a mesh spacing of between 7.0 x 10-5 and 8.0 x 10-5

μm. Fine screens of this type are extremely fragile and must be used with great

care.

A

series of suitable sieve cloths is described in the Fine Mesh series of British

Standard (BS) 410:1962. This specifies the gauge of the wire and the permitted

weaving tolerances. In successive meshes of this series, the mesh space alters

by a factor of 4√2. In the mesh series commonly chosen for size analysis,

16-22-30-44-60-85-120-170, alternate screens are selected so that the mesh

spacing decreases by √2 and the area of the apertures is halved. For classification,

one or more meshes of suitable weave can be chosen from this series and mounted

in a frame.

In

operation, the mesh should be lightly loaded so that all particles capable of

passing the mesh (undersize) have a chance to do so. The mesh must, therefore,

be agitated both to ensure access of particles to the holes and to clear holes

blocked by particles just unable to pass. Under these conditions, the rate of

sieving is proportional to the number of undersize particles on the screen. It

therefore decreases exponentially.

Most

screening, particularly that of coarse materials, is carried out dry. The wet

screening of dilute slurries is adopted for powders that aggregate strongly,

clog the mesh, or become electrostatically charged by the vibrations of the

screen. Sieving errors arising from the cohesion of small and large particles

and the retention of the former on a coarse mesh are avoided. Wet screening is

particularly useful if the subsequent process is wet and drying is unnecessary.

For

small-scale classification, test sieves with meshes conforming to BS 410 can be

used. The mesh is mounted on a circular brass frame, 8, 12, or 18 in. in

diameter, a rim on the lower edge enabling it to “nest” with the sieve below.

When the chosen sieves are equipped with a lid and a receiving pan, the

agi-tated assembly becomes an effective small-scale grading unit. Sieving is

stopped when the rate at which particles pass the mesh has reached some low

value or after some predetermined time at which the rate is known to be low.

As

the scale of the operation increases, it becomes, in general, less precise. For

continuous screening, the feed material is made to move across the screen to a

point of discharge. The residence time on the screen is usually short, and many

undersize particles traverse it without falling through. With increase of

sieving area, the meshes become more fragile and the finest meshes must be

supported with a coarser wire. An example of a large-scale separator utilizes a

circular screen of up to 5 ft in diameter and is vibrated in a horizontal

plane, the gyratory movement being imparted by an out-of-balance fly wheel

connected to the assembly. In other machines, the mesh is rectangular and

inclined at a shallow angle (5○–30○). A gyratory

movement is developed, and the material to be classified is fed to the top end.

These machines may bear more than one deck, thus allowing the separation of the

powder into several fractions at one time.

Elutriation and Sedimentation

The

balance of the drag force on the particle and the forces promoting move-ment

occurs at the terminal velocity. This velocity depends, among other things, on

the size of the particle, and it is the property on which several classifiers

are based. The fluid is either air or a liquid. The latter affords a higher

precision because dispersion can be more thorough. High shear forces cannot be

developed and dispersing agents cannot be used in air.

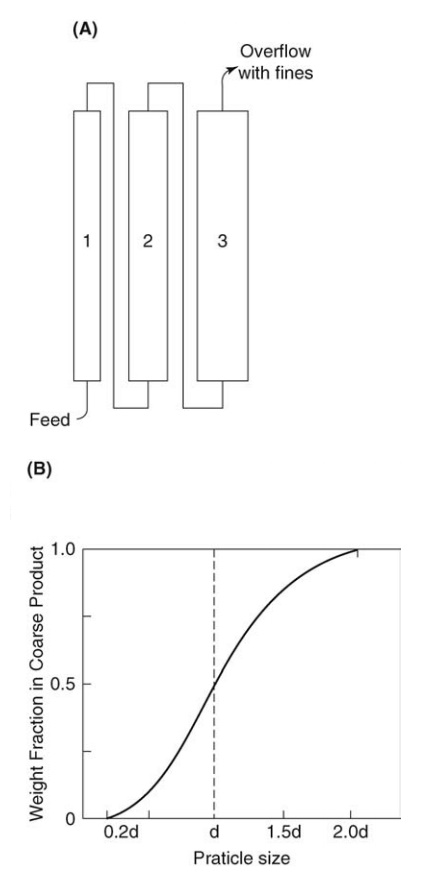

FIGURE 12.7 (A) An elutriator and (B) grade efficiency curve.

The

simplest classifier is a rising current of fluid in which the particles are

suspended. In this case, the force opposing the upward drag is gravitational.

If the opposition gives a terminal velocity greater than the current speed, the

particle will fall. This is the principle of elutriation, and the particle

size, d, at which the separation is made follows from a rearrangement of

equation (2.24) in chapter 2 for conditions in which Stokes’ law is valid.

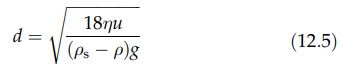

where

ρs - ρ is the density difference between

solid and fluid, η is the viscosity of the fluid, and m is the speed of the upward current.

The

elutriator shown in Figure 12.7A consists of three tubes. The first is smallest

in diameter and offers the highest upward liquid velocity. Coarse particles

with a high terminal velocity settle in this tube, while the remainder are

swept to the bottom of the second. The diameter of the second tube exceeds that

of the first, and elutriation speeds are lower. Only fine particles are swept

into the third tube where the process is repeated at a finer size. In this way,

the original slurry is divided into four fractions.

In

practice, fluctuations in flow conditions due to natural convection and a

violation of the conditions for which Stokes’ law is valid blur the point of

sep-aration. The evaluation of the separation must, therefore, take account of

the fine particles that fall with the coarse particles and the coarse particles

that move to the fine fraction. This is best expressed by a grade efficiency

curve. Returning to equation (24) in chapter 2, a particle of size d should be

stationary in the elu-triation tube. Because of fluctuating conditions, it

eventually resides with either

FIGURE 12.8 Cyclone separator.

The weight fraction in

each is, therefore, 0.5 at this particular size. We shall assume that of the

particles that are twice this size (2d), virtually all appear in the coarse

product.

The

weight fraction here is 1. Similarly, all particles of size 0.2d move to the fine product so that the

weight fraction in the coarse product is 0. As shown in Figure 12.7B, a sigmoid

curve, passing through 0.5 at size d,

links these extremes. The closer these extremes and the steeper the curve, the

more efficient the separation. A grade efficiency curve of this type can be

used as an appraisal of any sedimentor or elutriator.

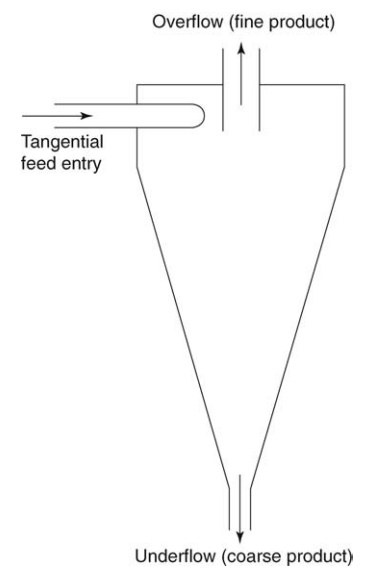

Gravitational

sedimentation is not of great importance in small-scale classification.

Sedimentation in a spinning fluid stream is, however, widely used. The most

common classifier of this type is the cyclone separator shown in Figure 12.8.

The fluid enters tangentially and acquires an intense spinning motion,

spiraling downward into the cone before rising to the outlet as a central core.

The inlet speed is very high so that large angular velocities are developed.

Because of centrifugal force, particles move radially across the spinning

stream to fall at the wall into the cone. Operated in this way, complete

separation of solids occurs, and the cyclone is, therefore, an effective air cleaner.

Operated with lower centrifugal forces, the cyclone transports the finest

particles to the exhaust, leaving the coarser particles to fall into the cone.

Cyclone classifiers are designed for use with either liquid or air.

The

centrifuge is normally operated to completely separate two phases. If, however,

the rate at which the feed passes through does not allow all particles to

settle, the action of a classifier is developed. This is illustrated by a solid

bowl centrifuge, which consists of a steel shell in the form of a frustrum

mounted horizontally. It contains a conveying screw at the wall, which rotates

at a slightly higher speed than the shell. Particles that settle at the wall

are conveyed to the narrow end of the shell and discharged. Fine particles are

entrained with the overflow to the other end. Further details of this and other

centrifugal classifiers have been given by Treasure (Treasure, 1965).

Related Topics