Flow Measurement

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Fluid Flow

The Bernoulli theorem can also be applied to the measurement of flow rate. Consider the passage of an incompressible fluid through the constriction.

FLOW MEASUREMENT

The

Bernoulli theorem can also be applied to the measurement of flow rate. Consider

the passage of an incompressible fluid through the constriction shown in Figure

2.6. The increase in kinetic energy as the velocity increases from u1

to u2 is derived from the pressure energy of the fluid, the pressure

of which drops from P1 to P2, the latter being recorded

by manometers. There is no change in height, and equation (2.5) can be

rearranged to give

The

volumetric flow rate Q =

u1a1 =

u2a2. Therefore, by rearrangement,

This

derivation neglects the correction of kinetic energy loss due to non-uniformity

of flow in both cross sections and the frictional degradation of energy during

passage through the constriction. This is corrected by the introduction of a

numerical coefficient, CD, known as the coefficient of discharge.

Therefore,

The

value of CD depends on conditions of flow and the shape of the

constriction. For a well-shaped constriction (notably circular cross section),

it would vary between 0.95 and 0.99 for turbulent flow. The value is much lower

in laminar flow because the kinetic energy correction is larger. The return of

the fluid to the original velocity by means of a diverging section forms a

flow-measuring device known as a Venturi meter.

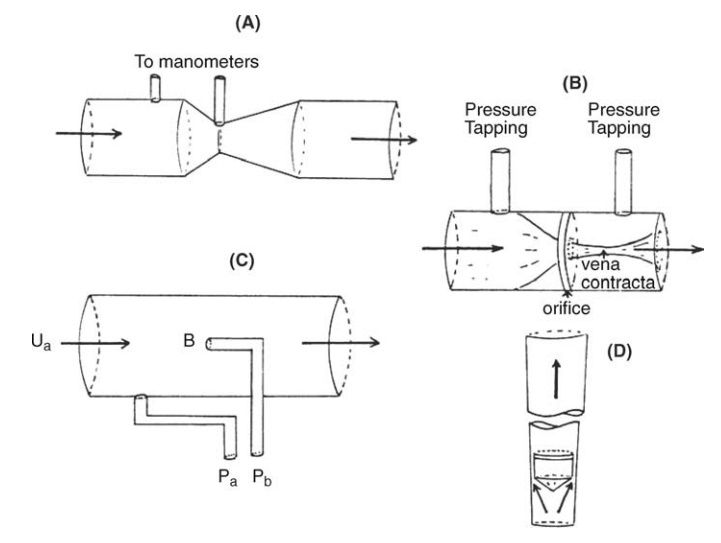

The

Venturi meter is shown in Figure 2.7A. The converging cone leads to the

narrowest cross section, known as the throat. The change in pressure is

measured across this part of the meter and the volumetric flow rate is found by

substitution into equation (2.11). Values of the coefficient of discharge are

given in the preceding paragraph. The diverging section or diffuser is designed

to induce a gradual return to the original velocity. This minimizes eddy

formation in the diffuser and permits the recovery of a large proportion of the

increased kinetic energy as pressure energy. The permanent loss of head due to

friction in both converging and diverging sections is small. The meter is

therefore efficient.

When

the minimization of energy degradation is less important, the gradual, economic

return to the original velocity may be abandoned, compen-sation for loss of

efficiency being found in a device that is simpler, cheaper, and more adaptable

than the Venturi meter. The orifice meter, to which this state-ment applies,

consists simply of a plate with an orifice. A representation of flow through the

meter is depicted in Figure 2.7B, indicating convergence of the fluid stream

after passage through the orifice to give a cross section of minimum area

called the vena contracta. The downstream pressure tapping is made at this

cross

FIGURE 2.7 Flow meters: (A) Venturi meter,

(B) orifice meter, (C) Pitot tube, and (D) rotameter.

The volumetric flow rate would be given by equation (2.6) for which a2

is the jet area at the vena contracta.

The measurement of this dimension is inconvenient. It is therefore related to

the area of the orifice, a0,

which can be accurately measured by the coefficient of contraction, Cc,

defined by the relation

Cc = a2/a0

The

coefficient of contraction, frictional losses between the tapping points, and

kinetic energy corrections are absorbed in the coefficient of discharge. The

volumetric flow rate is then

The

term [1 - (a02/a12)] approaches

unity if the orifice is small compared to the pipe cross section. Since P1

- P2 = Δhρg, Δh being the

difference in head developed by the orifice, equation (2.12) reduces to

Q

= CD a0 (2Δhg)1/2 (2:13)

The

value of CD for the orifice meter is about 0.6, varying with

construction, the ratio a0/a1, and flow conditions

within the meter. Because of its complexity, it cannot be calculated. After

passage through the orifice, flow disturbance during retardation causes the

dissipation of most of the excess kinetic energy as heat. The permanent loss of

heat is therefore high, increasing as the ratio of a0/a1

falls, ultimately reaching the differential head produced within the meter.

When constructional requirements and methods of installation are followed, the

cor-recting coefficients can be derived from charts. Alternatively, the meters

can be calibrated.

The

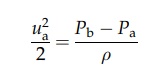

Bernoulli theorem may be used to determine the change in pressure caused by

retardation of fluid at the upstream side of a body immersed in a fluid stream.

This principle is applied in the Pitot tube, shown in Figure 2.7C. The fluid

velocity is reduced from ua, the velocity of the fluid filament in

alignment with the tube, to zero at B, a position known as the stagnation

point. The pressure, Pb, is measured at this point by the method

shown in Figure 2.7C. The undisturbed pressure, Pa, is measured in

this example with a tapping point in the wall connected to a manometer. Since

the velocity at B is zero, equation (2.10) reduces to

and

ua can be calculated. Since only a local velocity is measured,

variation of velocity in a section can be studied by altering the position of

the tube. This procedure must be used if the flow rate in a pipe is to be

measured. The mean velocity is derived from velocities measured at different

distances from the wall. This derivation and the low pressure differential

developed render the Pitot tube less accurate than either the Venturi tube or

the orifice meter for flow measure-ment. However, the tube is small in

comparison with the pipe diameter and therefore produces no appreciable loss of

head.

The

rotameter (a variable area meter),

shown in Figure 2.7D, is commonly used, giving a direct flow rate reading by

the position of a small float in a vertical, calibrated glass tube through

which the fluid is flowing. The tube is internally tapered toward the lower end

so that the annulus between float and wall varies with the position of the

float. Acceleration of the fluid through the annulus produces a pressure

differential across the position of the float and an upward force on it. At the

equilibrium position, which may be stabilized by a slow rotation of the float,

this upward force is balanced by the weight force acting on the float. If the

equilibrium is disturbed by increasing the flow rate, the balance of weight

force and the pressure differential are produced by movement of the float

upward to a position at which the area of the annulus is bigger. For accurate

measurement, the rotameter is calibrated with the fluid to be metered. Its use

is, however, restricted to that fluid.

Related Topics