Gaseous Sterilization - Sterilization Methods

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Sterilization Procedures And Sterility Assurance

The chemically reactive gases ethylene oxide [(CH 2) 2 O] and formaldehyde [(methanal, H.CHO)] possess broad-spectrum biocidal activity, and have found application in the sterilization of reusable surgical instruments, certain medical, diagnostic and electrical equipment, and the surface sterilization of powders.

GASEOUS STERILIZATION

The chemically reactive gases ethylene

oxide [(CH 2) 2 O] and formaldehyde [(methanal, H.CHO)]

possess broad-spectrum biocidal activity, and have found application in the

sterilization of reusable surgical instruments, certain medical, diagnostic and

electrical equipment, and the surface sterilization of powders. Sterilization

processes using ethylene oxide sterilization are far more commonly used on an

international basis than those employing formaldehyde.

Ethylene oxide treatment can also be considered as an alternative to

radiation sterilization in the commercial production of disposable medical

devices . These techniques do not, however, offer the same degree of sterility

assurance as heat methods and are generally reserved for temperature-sensitive

items.

The mechanism of antimicrobial action

of the two gases is assumed to be through alkylation of sulphydryl, amino,

hydroxyl and carboxyl groups on proteins and imino groups of nucleic acids. At

the concentrations employed in sterilization protocols, type A survivor curves (Figure 21.1)

are produced, the lethality of these gases increasing in a non-uniform manner

with increasing concentration, exposure temperature and humidity. For this

reason, sterilization protocols have generally been established by an empirical

approach using a standard product load containing suitable biological indicator

test strips (section 12.3). Concentration ranges (given as weight of gas per

unit chamber volume) are usually of the order of 800–1200 mg/L for ethylene

oxide and 15–100 mg/L for formaldehyde, with operating temperatures in the region

of 45–63 °C and 70–75 °C, respectively. Even at the higher concentrations and

temperatures, the sterilization processes are lengthy and therefore unsuitable

for the re sterilization of high-turnover articles. Further delays occur

because of the need to remove toxic residues of the gases before release of the

items for use. In addition, because recovery of survivors in sterility tests is

more protracted with gaseous sterilization methods than with other processes,

an extended quarantine period may also be required.

As alkylating agents, both gases are

potentially mutagenic and carcinogenic (as is the ethylene chlorohydrin that

results from ethylene oxide reaction with chlorine); they also produce symptoms

of acute toxicity including irritation of the skin, conjunctiva and nasal

mucosa. Consequently, strict control of their atmospheric concentrations is

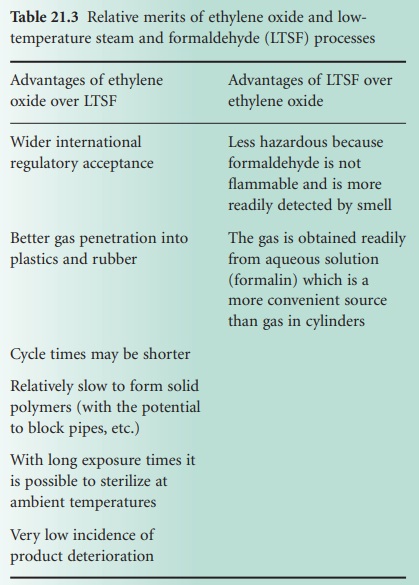

necessary and safe working protocols are required to protect personnel. Table 21.3 summarizes

the comparative advantages afforded by ethylene oxide and low-temperature steam

and formaldehyde (LTSF) processes.

a) Ethylene Oxide

Ethylene oxide gas is highly explosive in mixtures of more than 3.6% v/v

in air; in order to reduce this explosion hazard it is usually supplied for

sterilization purposes as a 10% mix with carbon dioxide, or as an 8.6% mixture

with HFC 124 (2-chloro-1,1,1,2 tetrafluoroethane), which has replaced

fluorinated hydrocarbons (freons). Alternatively, pure ethylene oxide gas can

be used below atmospheric pressure in sterilizer chambers from which all air

has been removed.

The efficacy of ethylene oxide treatment depends on achieving a suitable

concentration in each article and this is assisted greatly by the good

penetrating powers of the gas, which diffuses readily into many packaging

materials including rubber, plastics, fabric and paper. This is not without its

drawbacks, however, as the level of ethylene oxide in a sterilizer will

decrease due to absorption during the process and the treated articles must

undergo a desorption stage to remove toxic residues. Desorption can be allowed

to occur naturally on open shelves, in which case complete desorption may take

many days, e.g. for materials like PVC, or it may be encouraged by special

forced-aeration cabinets where flowing, heated air assists gas removal,

reducing desorption times to between 2 and 24 hours.

Organisms are more resistant to ethylene oxide treatment in a dried

state, as are those protected from the gas by inclusion in crystalline or dried

organic deposits. Thus, a further condition to be satisfied in ethylene oxide

sterilization is attainment of a minimum level of moisture in the immediate

product environment. This requires a sterilizer humidity of 30–70% and

frequently a preconditioning of the load at relative humidities of more than

50%.

i) Sterilizer design and

operation

An ethylene oxide sterilizer consists of a leak-proof and explosion-proof

steel chamber, normally of 100–300 L capacity, which can be surrounded by a

hot-water jacket to provide a uniform chamber temperature. Successful operation

of the sterilizer requires removal of air from the chamber by evacuation,

humidification and conditioning of the load by passage of sub atmospheric-pressure

steam followed by a further evacuation period and the admission of preheated

vaporized ethylene oxide from external pressurized canisters or single-charge

cartridges. Forced gas circulation is often employed to minimize variations in

conditions throughout the sterilizer chamber. Packaging materials must be air,

steam-and gas-permeable to permit suitable conditions for sterilization to be

achieved within individual articles in the load. Absorption of ethylene oxide

by the load is compensated for by the introduction of excess gas at the beginning

or by the addition of more gas as the pressure drops during the sterilization

process. The same may also be true for moisture absorption, which is

compensated for by supplementary addition of water to maintain appropriate

relative humidity.

After treatment, the gases are

evacuated either directly to the outside atmosphere or through a special

exhaust system. Filtered, sterile air is then admitted either for a repeat of

the vacuum/air cycle or for air purging until the chamber is opened. In this

way, safe removal of the ethylene oxide is achieved, reducing the toxic hazard

to the operator. Sterilized articles are removed directly from the chamber and arranged

for desorption. The operation of an ethylene oxide sterilizer should be

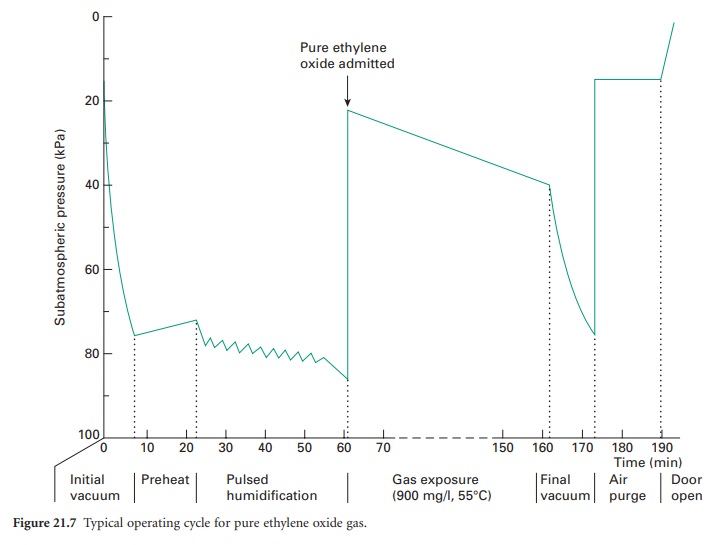

monitored and controlled automatically. A typical operating cycle for pure

ethylene oxide gas is shown in Figure 21.7.

b) Formaldehyde

Formaldehyde gas for use in sterilization is produced by heating formalin (37% w/v aqueous solution of formaldehyde) to a temperature of 70–75 °C with steam,

leading to the process

known as LTSF. Formaldehyde has a similar toxicity to ethylene oxide and although absorption

to materials appears

to be lower, similar

desorption routines are recommended. A major disadvantage of formaldehyde is low penetrating power, and this limits

the packaging materials that

can be employed to principally paper and cotton fabric.

i) Sterilizer design and operation

An LTSF sterilizer is designed to operate with

sub-atmospheric-pressure steam.

Air is removed by evacuation and steam

is admitted to the chamber

to allow heating of the load

and to assist

in air removal. The sterilization period starts

with the release

of formaldehyde by vaporization

from formalin (in a vaporizer with a steam jacket) and continues through

either a simple

holding stage or through a series of pulsed evacuations and steam and formaldehyde admission cycles. The chamber temperature is maintained by a thermostatically controlled water jacket,

and steam and condensate are removed

via a drain channel

and an evacuated condenser. At the end of the treatment period

formaldehyde vapour is expelled by steam

flushing and the load is dried by alternating stages

of evacuation and

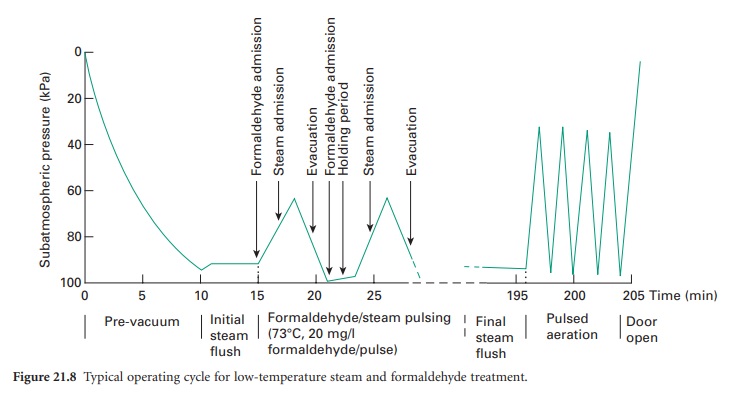

admission of sterile, filtered air. A typical

pulsed cycle of operation is shown in Figure 21.8.

c) Peroxygen Compounds

Hydrogen

peroxide (H2O2),

30–35%w/v, and peracetic acid (CH3CO3H), 3.5%w/v,

are used as highly effective

oxidizing agents

to kill microorganisms. The liquids

are heated to vaporize them and are held

in a sealed chamber where

all surfaces which

come into contact with the vapour

will be sterilized. These methods are widely

used for the sterilization of equipment used for

aseptic preparation and manufacture such

as isolators, with

the vaporized hydrogen

peroxide (VHP) often used for the routine

decontamination of cleanrooms.

Related Topics