Manufacture of Drugs

| Home | | Forensic Pharmacy |Chapter: Forensic Pharmacy : The Drugs and Cosmetics Act (DCA) 1940 and Rules 1945

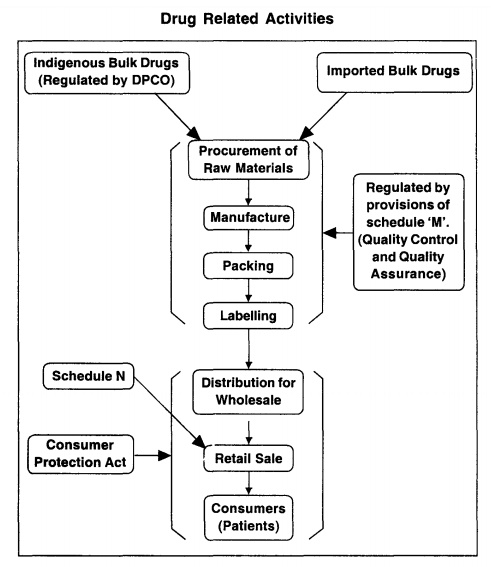

Manufacture in relation to any drug includes any process or part of a process for making, altering, finishing, packing, labelling, breaking up or otherwise treating or adopting any drug with a view to its sale and distribution, but does not include compounding or dispensing of any drug or packing of any drug in ordinary course of retail business.

Manufacture of Drugs

Definition: Manufacture in

relation to any drug includes any process or part of a process for making,

altering, finishing, packing, labelling, breaking up or otherwise treating or

adopting any drug with a view to its sale and distribution, but does not

include compounding or dispensing of any drug or packing of any drug in

ordinary course of retail business.

Manufacture

of drugs is a blend of art and science, to be achieved strictly in accordance

with the provisions of Good Manufacturing Practices (GMP). A person who is

interested in starting manufacturing of drugs is required to fulfill several

conditions laid down in DCA and Rules. The conditions to be fulfilled before

licence is granted are collectively called as "Conditions Precedent"

and conditions that are required to be fulfilled after the licence is obtained

for manufacturing are called "Conditions Subsequent". The Licensing

Authority is both in States and at Central Government. The Central Government

is empowered to prohibit manufacturing and sale of any drug formulation in

public interest.

Licences are

required for the manufacturing of following categories of drugs.

1. Manufacturing of drugs belonging to Schedules C and C (I)

2. Manufacturing of drugs belonging to Schedule X

3. Manufacturing of drugs belonging to Schedules C, C (I)

and X

4. Manufacturing of drugs other than Schedule C, C, and X

5. Manufacturing of drugs for examination, test or analysis

6. Loan licences

7. Licence for Repacking

The following

categories of drugs and cosmetics are prohibited to be manufactured or sold in

our country.

1. Any drug or

cosmetic which is substandard, misbranded, adulterated or spurious.

2. Any patent or

proprietory medicine without clear indication of ingredients.

3.

Any drug claiming for accurate cure or prevention of diseases listed in

Schedule].

4. Any manufacturing

of formulation containing drug or cosmetic which has been imported into our

country in contravention to the provisions of the Act and Rules.

5. Manufacturing for

sale of any drug or cosmetic containing any harmful ingredient.

6. Manufacturing for sale of any drug or cosmetic in

contravention to the provisions of the Act and Rules, provided that manufacture

of small quantities of any drug for the purpose of examination, test or

analysis is permitted, subject to prescribed conditions.

Separate

applications for separate licences for more than one premises of manufacture

are required to be made.

(A) Manufacturing of Drugs other than Schedules C and C (1)

Application for

grant of licence or renewal is made in Form 24. The licence is issued by

Licensing Authority in Form 25.

I - Conditions for grant of Licence are as follows:

1. Competent Staff: (i) A graduate in

Pharmacy/Pharmaceutical Chemistry

with a minimum of 18 months of

experience after graduation. The duration may be reduced by 6 months, if the

applicant has undergone training during graduation. or (ii)A graduate in

Science with Chemistry as a principal subject and with 3 years of manufacturing

experience after graduation or (iii) A graduate in Chemical Engineering or

Chemical Technology or Medicine with 3 years of manufacturing experience after

graduation or (iv) holding equivalent foreign qualification.

For disinfectant

fluids. insecticides, liquid paraffin, non-chemical contraceptives, surgical

dressings, medicinal gases, plaster of paris, only adequate experience in

manufacturing is required and no specific qualification is mentioned

2. Factory premises: As per Schedule' M' with regard to

premises, space, plant and

equipment.

3. Separate facilities for analysis of raw materials

and finished formulations

There should be

separate head of department for analysis and manufacturing sections. Head of

the testing and analytical department should be a graduate in

Medicine/Pharmacy/Pharmaceutical Chemistry/Science with adequate experience in

analysis.

4. There should be

adequate arrangement of storage of raw materials and finished products.

5. While applying for

licence to manufacture patent or proprietary medicines, it is required to

submit evidence justifying therapeutic claims of the product, its stability and

safety.

II. Conditions to be fulfilled after getting a licence:

1. The manufacturer

should always maintain adequate staff, sufficient premises and equipment.

2. The manufacturing

records, records for raw material and analysis and other operational records

should be maintained as per Schedule 'U'.

3.

The licensee should own an analytical laboratory or get tested the samples

analysed in an approved analytical laboratory.

The records for

analysis are required to be maintained for a period of 5 years from date of

manufacturing. The records are both for manufacturing and for finished product.

4. The manufacturer

should allow the Inspector to inspect the premises, manufacturing process,

analytical procedures, and withdraw the samples. The samples may be provided on

demand and entire protocol of manufacturing should be made available when asked

for. The manufacturer should also withdraw the batch manufactured by him if

directed to do so by the Controlling Authority.

5. The manufacturer

should comply with all the requirements of the Act and Rules thereunder.

6. The manufacturer should maintain the Inspection Book.

7. Samples with expiry date should be maintained for 6

months after expiry date. For other categories, the samples should be

maintained for 3 years from the date of manufacturing. Twice the lot of

reference samples should be maintained. The quantity maintained should be

sufficiently available for analysis.

8. Any change in the

staff structure especially, technical staff should be reported to Licencing

Authority.

9. Any major

structural change in the premises should be done with the permission of

Licencing Authority

10. The manufacturer

should forward all the sales records to the Controlling Authority.

[B] Manufacture of Drugs for Testing, Analysis or Examination

If

the manufacturer does not hold separate licence for test, analysis or

examination, the licence is obtained in Form 29. The provisions relating prohibition

of manufacturing of certain drugs do not apply for such manufacturing meant for

test or analysis. The validity of the licence is for I year. The manufactured

drugs should be kept in containers bearing appropriate label indicating the

purpose of test or analysis. When the material is supplied to other

manufacturer, the label stating the name and address of manufacturer,

scientific name of the drug, licence number, date of manufacture, etc., should

be provided.

The

manufacturer should allow the Inspector to inspect the premises, manufacturing,

and analytical records and withdraw the samples if required for analysis. The

manufacturer should comply with the provisions of the Act and Rules. The manufacturer

should maintain an Inspection Book and the same be shown to the Inspector.

[C] Manufacturing of New Drugs

In addition to

provisions for manufacture of drugs, there should be documentary evidence for

qual ity, purity, therapeutic trials of new drugs and evidence for approval

under schedule 'Y' (Clinical trials).

[D] Loan Licences

For

drugs other than Schedules C, (I) and X, loan licences can be given. A

qualified person can make use of approved facilities of manufacturing provided

by any other person and obtain a loan licence for manufacture of drugs other

than Schedules C, C (I) and X. The licensee in such cases should convice the

Licensing Authority about the availability of the infrastructure on loan from

approved manufacturer, and also be convinced about the need to grant such a

loan licence.

All

the conditions of GMP in Schedule 'M' are required to be fulfilled.

Manufacturing Records should be maintained for 5 years. In case of drugs with

date of expiry, the records should be maintained for 2 years. Application for

grant or renewal of loan licence is made in Form 24-A. The licence is issued by

Licensing Authority in Form 25-A, which is valid for I year.

[E] Repacking licence

It is issued for drugs

other than Schedules C, C1 and X, subject to fulfillment of conditions. The

application is made for grant or renewal of licence in Form 24-B. The licence

is issued by Licensing Authority after inspection in Form 25-B.

There should be

adequate arrangement for testing of samples. The licence should always be

displaced at premises of repacking. The factory primises for repacking should

comply with provisions of Schedule M. Hygienic conditions of working should

always be maintained. Adequate staff should be appointed and any change in

staff structure should be immediately informed to Controlling Authority.

The

Competent person eligible to get Repacking Licence is -

1. Diploma in pharmacy or Registered pharmacist

2. Intermediate with Chemistry as a subject

3. Matriculation

with 4 years of experience in manufacture, dispensing or repacking of drugs.

The licence is valid

till 3st December every year and required to be renewed. There should be

separate application for separate licence.

The

container or package of repacked drug should bear on its label the words - "Rpg.Lic.No".

The Repacking Licence is given to the competent persons for the bulk drugs or

drug formulations procured in large quantities from manufacturer directly and

required to be sold in small quantities.

[F] Manufacture of Drugs under Scheaules C and C (1) and Drugs specified in Schedules C, C (1) and X

Application

for grant or renewal of a licence is made for Schedules C and C (1) drugs in

Form-27 and for Schedules C, C (1) and X in

Form 27-B. The licence is

issued in Form-28 for manufacture of

Schedules C and C (1) drugs and in Form

28-B for drugs under Schedules C, C (I) and X.

1. The conditions

stipulated in Schedule 'M' should be met with. The requirements of space,

plant, equipment, etc., should be as per Schedule M.

2. The testing

strength or quality strength of the manufacturing un it should be assessed.

There should be a qualified independent head for analytical wing including for

analysis of Schedules C and C (1)

drugs.

3. The competent technical persons should be available with

one of the following qualifications.

(i) A graduate in

Pharmacy/Pharmaceutical Chemistry with 18 months of experience after graduation

in manufacturing drugs to which licence applies. Six months of mandatory

training after graduation can form part of this total training of 18 months.

or

A graduate in

Science with Chemistry or Microbiology as major subject with a minimum of 3

years of experience after graduation in the manufacture of drugs to which this

licence applies.

or

A foreign equivalent

qualification or an expert in manufacturing before 29th June, 1957.

For

manufacture of veterinary Scheduled drug formulations, a graduate in

Medicine/Veterinary Science/General Science/ Pharmacy with minimum 3 years

experience in manufacture of biological products.

4. There should be

facilities available for storage of drugs. Sufficient precaution should be

taken for preserving the properties of manufactured drugs.

5. Records of

manufacturing should be maintained as per Schedule 'U'. Records of test, analysis

and examination and batch wise records are required to be maintained. All

records should be kept for a period of 2 years from the date of expiry of drug.

In other cases, with no expiry date, the records should be kept for 5 years

from the date of manufacturing.

6. The manufacturer

should allow the Inspector or the representative of Controlling Authority and

Licensing authority to visit manufacturing premises with or without notice.

7. The manufacturer

should report to the Licensing Authority any changes in staff or any material

changes.

8. The licensee should furnish the sample of drugs to the

Inspector when asked for purpose of analysis. He should not sell the drug if

asked to do so by Controlling Authority and withdraw the drug already sold from

the market on direction from the Authority

9. The licensee

should maintain the Inspection Book to enable the Inspector to record his

observations.

Related Topics