Manufacture of Sterile Products

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Principles Of Good Manufacturing Practice

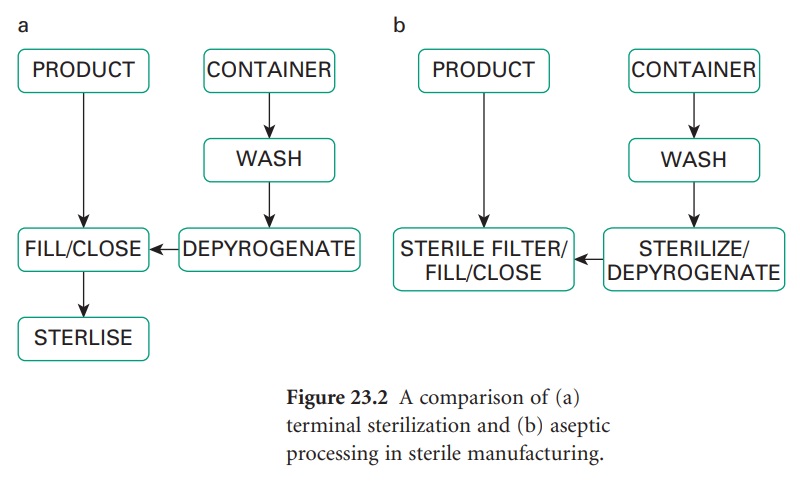

For production purposes an important distinction exists between sterile products which have been terminally sterilized and those which have not. Terminal sterilization involves the product being sealed in its container and then sterilized, usually by heat, but ionizing radiation or, less commonly, ethylene oxide may be employed.

MANUFACTURE OF

STERILE PRODUCTS

For production purposes an important distinction

exists between sterile products which have been

terminally sterilized (Figure

23.2a) and those which have not. Terminal

sterilization involves the

product being sealed in its container and then sterilized, usually by heat, but ionizing radiation or, less

commonly, ethylene

oxide may be employed. Such a product

must be manufactured in a clean

area. A product which cannot

be terminally sterilized is prepared aseptically

(Figure 23.2b) from

previously sterilized materials or by sterile filtration; in either case, aseptic filling

is a poststerilization step. Strict

aseptic conditions are

required throughout.

Vaccines, consisting of dead microorganisms, microbial extracts or inactivated viruses may be filled

in the same premises as other sterile

medicinal products, so the completeness of killing or removal of live organisms must be validated before

processing. Separate premises are needed for the filling

of live or attenuated vaccines and for the preparation of

other products derived from

live organisms. Non-sterile products and sterile

products must not be processed in the same area.

A) Clean And Aseptic Areas: General Requirements

i) Design of premises

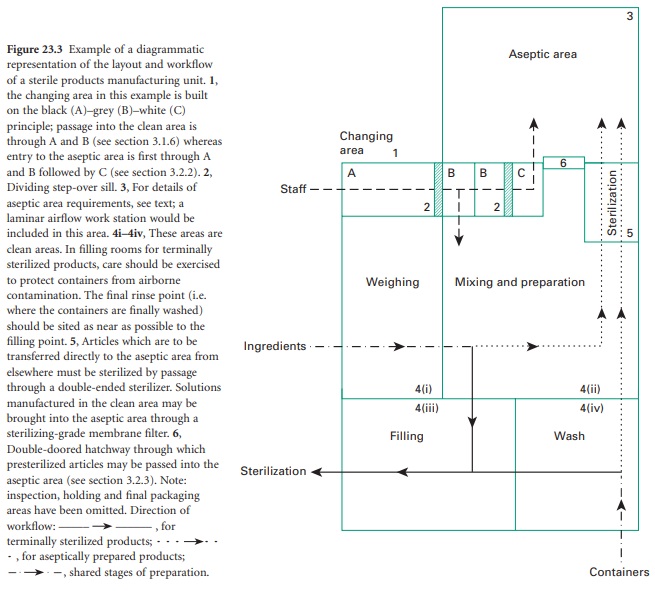

Sterile production should be carried

out in a purposebuilt unit separated

from other manufacturing areas and

thoroughfares. The unit should be designed to encourage

separation of each stage of production but should ensure a safe and organized workflow. A plan of such a facility

is shown in Figure

23.3. Sterilized products

held in quarantine pending sterility test results must be kept separate from those awaiting

sterilization.

ii) Internal Surfaces, fittings and floors

Particulate, as well as microbial,

contamination must be prevented.

To this end all surfaces must be smooth

and impervious in order

to: (1) prevent

accumulation of dust or other particulate matter; and (2) permit

easily repeated cleaning and disinfection. Smooth rounded coving should be used where the wall meets the floor and the ceiling.

Suitable flooring may be provided

by welded sheets

of PVC; cracks

and open joints which might harbour dirt and microorganisms must be avoided.

The preferred surfaces for walls

are plastic, epoxy-coated plaster, plastic

fibreglass or glass-reinforced polyester. Often the final finish for the floor, wall

and ceiling is achieved using continuous welded PVC sheeting. False ceilings should

be adequately sealed to prevent

contamination from the space above. Use should

be made of well-sealed glass panels, especially in dividing walls,

to ensure good visibility and allow satisfactory supervision. Doors and windows should be flush with the walls. Windows

should not be openable.

Internal fittings

such as cupboards, drawers and shelves should be kept

to a minimum. They must

be sited where they do not interfere with the laminar

flow of the

filtered air supply.

Stainless steel or laminated plastic

are the preferred materials for such fittings.

Stainless steel trolleys may be used to transport equipment

and materials within the clean and aseptic areas

but must remain confined to their respective units. Equipment must be

designed so that it may be easily

cleaned and sterilized or disinfected.

iii) Services

Clean and aseptic areas must be adequately illuminated; lights are best housed in translucent panels

set in a false ceiling. Electrical switches

and sockets must

be flush with the wall or fitted outside. When required, gases should be pumped in from

outside the unit.

Pipes and ducts,

if they must be brought

into the clean

area, must be sealed

through the walls. Additionally, in order to prevent dust accumulation,

pipes and ducts must be boxed in or

readily cleanable.

Alternatively, they may be sited above false ceilings.

Sinks should be of stainless steel with no overflow,

and water must

be of at least potable

quality. Wherever possible, drains should be avoided. If installed they must be fitted with effective, readily

cleanable traps and with air breaks to prevent

backflow. Any floor

channels should be open, shallow and cleanable and connected to drains outside the area; they should

be monitored microbiologically. Sinks and drains

should be excluded

from aseptic areas except where radiopharmaceuticals are being processed when sinks

are a requirement.

iv) Air Supply

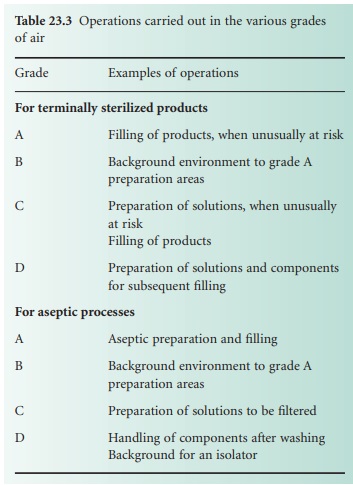

Areas for sterile

manufacture are classified according to the required characteristics of the environment. Each operation requires an appropriate level

of microbial and particulate cleanliness; four grades are specified in The

Rules and Guidance for Pharmaceutical Manufacturers and Distributors (2007). Environmental

quality is substantially influenced by the air supplied to the manufacturing environment. The grades of

air required for specific manufacturing activities are listed

in Table 23.3.

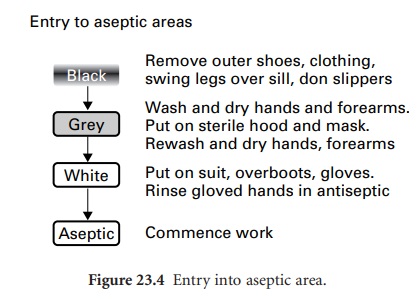

Filtered air is

used to achieve

the necessary standards; this should be maintained at positive pressure throughout a clean

or aseptic area, with the highest pressure in the most critical

rooms (aseptic or clean

filling rooms) and a progressive reduction through

the preparation and changing rooms (Figure 23.4); a minimum pressure

differential of 10 kPa is normally required between each class of room. A minimum of 20 changes of air per hour is usual in clean and aseptic

rooms. The air inlet points should

be situated in or

near the ceiling, with the final

filters placed as close as possible to the point

of input to the room.

Equipment or furnishings must be sited so as not to interfere with laminar flow.

The greatest risk of contamination of a product

comes from its immediate environment. Additional protection is needed both in the filling

area of the cleanroom and in

the aseptic suite. This can be provided by a workstation

supplied with a unidirectional flow

of filtered sterile

air. This is known as a laminar

flow cabinet. Displacement of air may be vertical or horizontal with

a typical homogeneous air flow of 0.45 m/s at the working

position. Consequently airborne

contamination is not added to the

work space, and any generated by manipulation is swept

away by the laminar

air currents. A fuller description of high efficiency particulate air (HEPA) filters in laminar

flow cabinets

is given by Gardner and

Peel (1998).

The efficacy

of the filters through which

the air is passed should be monitored at predetermined

intervals. Air quality

may be monitored for bacteria

and fungi by slit sampler or settle plate.

Particles are measured

using a discrete airborne particle

counter. The latest edition

of The Rules and Guidance for Pharmaceutical Manufacturers and Distributors (2007) states that particles must be monitored continuously in a grade A area and recommends it for grade

B areas. It should be noted that

grade A air is not the purest

that can be obtained; four

even cleaner grades are used in the electronics industry (ISO14644-1).

v)

Clothing

Clothing worn

in a clean area must

be of non-shedding fibres; polyester is a suitable

fabric. Airborne contamination, both microbial and particulate, is

reduced when trouser suits, close-fitting at the neck, wrists and ankles,

are worn.

Clean suits should

be provided once a day, but fresh headwear, overshoes and powder-free gloves are

necessary for each

working session. Special laundering facilities are desirable.

vi)

Changing facilities

Entry to a clean or aseptic

area should be through a changing room fitted

with interlocking doors;

this design acts as an airlock to prevent influx

of air from

the outside. This route is for personnel only, not

for the transfer of materials and equipment. Staff entering the changing

room should already be clad in the standard

factory or hospital protective clothing. For entry

into a clean area, passage through

the changing room should be from

a ‘black’

to a ‘grey’ area, via a dividing

step-over sill (Figure 23.4). Movement

through these areas

and finally into the cleanroom

is permitted only when observing a strict protocol, whereby

outer garments are removed in the

‘black’ area and cleanroom trouser

suits donned in the

‘grey’ area. Only

after hand-washing in a sink fitted

with elbowor foot-operated taps may the operator

enter the cleanroom.

vii)

Cleaning

and disinfection

A strict,

validated disinfection policy

is necessary if microbial contamination is to be kept to a minimum.

Cleaning agents

used include alkaline

detergents and ionic and non-ionic surfactants. A wide range

of chemical disinfectants is available. Clear, soluble phenolics are commonly

used for interior

services and fittings. Disinfectants for working surfaces

are alcohols (70% ethanol or isopropanol) or, less commonly,

chlorine-based agents

such as hypochlorites. Skin may be disinfected with cationic detergents such as cetrimide

or chlorhexidine, usually

formulated with 70% alcohol to avoid

the need for rinsing. Gloved

hands may be disinfected with

these detergents or 70% alcohol. The former have the advantage of offering residual

activity. Rotation of different disinfectants reduces the risk of the emergence of resistant strains,

but such rotation

should be validated. In-use dilutions

must not be used unless

sterilized. Disinfectants and detergents for

use in grade A/B areas must be sterile

prior to use and formulated with water for injections. Modern

sprays are fitted

with devices to prevent air being sucked

back, extending the life of the

disinfectant. Smooth polished surfaces are more readily

cleaned. Floors and horizontal surfaces should

be cleaned and disinfected daily,

walls and ceilings

as often as required, but the interval should not exceed

1 month. Regular

microbiological monitoring should be carried out to determine

the efficacy of disinfection procedures. Records must be kept

and immediate remedial action taken should normal levels for that area be exceeded.

viii)

Operation

The number

of persons involved in sterile manufacture should be kept to a minimum to avoid the inevitable

turbulence and shedding of particles and organisms associated with the operatives. All operations should

be undertaken in a controlled and methodical manner as

excessive activity may increase turbulence and particle shedding.

Containers made

from fibrous materials such as paper,

cardboard and sacking are generally heavily

contaminated (especially with moulds and bacterial spores) and should not be taken into clean areas. Ingredients which must be brought

into clean areas must first be

transferred to suitable

metal or plastic containers. Containers and closures for terminally sterilized products must be thoroughly cleaned before

use and should undergo a final washing and rinsing process

in apyrogenic distilled

water (which has been passed

through a bacteria-proof membrane filter)

immediately prior to filling. Containers and closures for use in aseptic manufacture must, in addition,

be sterilized after washing and rinsing in preparation for aseptic filling.

Related Topics