Mass Transfer in Turbulent and Laminar Flow

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Mass Transfer

When a fluid flows over a surface, the surface retards the adjacent fluid region, forming a boundary layer.

MASS TRANSFER IN TURBULENT AND

LAMINAR FLOW

As

already explained, movement of molecules across the streamlines of a fluid in

laminar flow can only occur by molecular diffusion. If the concentration of a

component, A, varies in a direction normal to the streamlines, the molar rate

of diffusion will be given by equation (4.1).

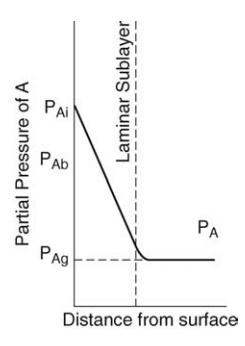

When

a fluid flows over a surface, the surface retards the adjacent fluid region,

forming a boundary layer. If flow throughout the fluid is laminar, the equation

for molecular diffusion may be used to evaluate the mass transferred across the

boundary layer. In most important cases, however, flow in the bulk of the fluid

is turbulent. The boundary layer is then considered to consist of three

distinct flow regimes. In the region of the boundary layer most distant from

the surface, flow is turbulent and mass transfer is the result of the

interchange of large portions of the fluid. Mass interchange is rapid, and

concentration gra-dients are low. As the surface is approached, a transition

from turbulent to laminar flow occurs in the transition or buffer region. In

this region, mass transfer by eddy diffusion and molecular diffusion are of

comparable magnitude. In a fluid layer at the surface, a fraction of a millimeter

thick, laminar flow conditions persist. This laminar sublayer, in which

transfer occurs by molecular diffusion only, offers the main resistance to mass

transfer, as shown in Figure 4.2.

FIGURE 4.2 Mass transfer at a boundary.

As

flow becomes more turbulent, the thickness of the laminar sublayer and its

resistance to mass transfer decrease.

One

approach to the evaluation of the rate of mass transfer under these conditions

lies in the postulation of a film, the thickness of which offers the same

resistance to mass transfer as the combined laminar, buffer, and turbulent

regions. The analogy with heat transfer by conduction and convection is exact,

and quantitative relations between heat and mass transfer can be developed for

some situations. This, however, is not attempted in this text. The postulate of

an effective film is explained by reference to Figure 4.2.

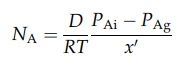

A

gas flows over a surface, and equimolecular counterdiffusion of com-ponents A

and B occurs, A away from the surface and B toward the surface. The variation

in partial pressure of A with distance from the surface is shown in the figure.

At the surface, the value is PAi. A linear fall to PAb

occurs over the laminar sublayer. Beyond this, the partial pressure falls less

steeply to the value PA at the edge of the boundary layer. PAg,

a value slightly higher than this, is the average partial pressure of A in the

entire system. In general, the gas content of the laminar layer is so small

that PA and PAg are virtually equal. If molecular

diffusion were solely responsible for diffusion, the partial pressure, PAg,

would be reached at some fictitious distance, x0, from the surface,

over which the concentration gradient (PAi – PAg)/x’ exists. The molar

rate of mass transfer would then be

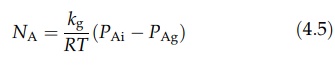

x' is not known, however, and this equation may be written as

where

kg, is a mass transfer coefficient, the unit of which is m/sec.

Since CA = PA/RT, we can also write

NA

= kg(CAi - CAg)

where

CAi and CAg are the gas concentrations at either side of

the film. Similar equations describe the diffusion of B in the opposite

direction.

Diffusion

across a liquid film is described by the equation

NA

= k1(CAi CAl) (4:6)

where

CAi is the concentration of component A at the interface and CAl

is its concentration in the bulk of the phase.

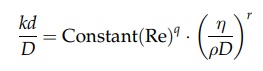

In

all cases, the mass transfer coefficient will depend on the diffusivity of the

transferred material and the thickness of the effective film. The latter is

largely determined by the Reynolds number of the moving fluid, that is, its

average velocity, its density, its viscosity, and some linear dimension of the

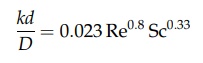

system. Dimensional analysis will give the following relation:

where

Re is the Reynolds number, k is the mass transfer coefficient, D is the

diffusivity, and d is a dimension

characterizing the geometry of the system.

This

relation is analogous to the expression for heat transfer by forced convection

given in chapter 3. The dimensionless group kd/D

corresponds to the Nusselt group in heat transfer. The parameter η/ρD is known as the Schmidt number and

is the mass transfer counterpart of the Prandtl number. For example, the

evaporation of a thin liquid film at the wall of a pipe into a turbulent gas is

described by the equation

where

Sc is the Schmidt number. Although the equation expresses experimental data,

comparison with equation (13) from the heat transfer section again

dem-onstrates the fundamental relation of heat and mass transfer.

Similar

relations have been developed empirically for other situations. The flow of

gases normal to and parallel to liquid surfaces can be applied to drying

processes, and the agitation of solids in liquids can provide information for

crystallization or dissolution. The final correlation allows the estimation of

the mass transfer coefficient with reasonable accuracy.

Related Topics