Process Analytical Technology

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Process Analytical Technology

To maximize the control over any process in pharmaceutical product development, information is required on the way in which the product is responding to changes in manufacturing variables.

Process Analytical

Technology

To

maximize the control over any process in pharmaceutical product development,

information is required on the way in which the product is responding to

changes in manufacturing variables. Historically, the information was derived

from data obtained on the nature of batches produced under particular

manu-facturing conditions. Knowledge of the batch properties were employed to

modify the manufacturing conditions to ensure that the product was closely

controlled to designated quality specifications.

In

recent years, analytical methods and their application have improved to the

point that real time in process measurements can be taken and fed back through

control systems to the input parameters to allow for continuous mon-itoring and

control of processes.

In

earlier chapters, examples of the major unit operations in pharmaceu-tical

manufacturing were outlined. These processes will now be considered with

anecdotal evidence from the literature of methods that might lead to closer

control of the product quality and thereby conform to recent regulatory

direc-tives to consider such methods as part of the Quality by Design (QbD)

initiative.

The

Food and Drug Administration has issued a guidance document on Process

Analytical Technology (PAT) (Zu et al., 2007). Processes may be divided into

batch and continuous approaches. These processes can be monitored by in situ,

real time, and/or feedback control analyses to assure the quality of the

product (Fig. 19.1).

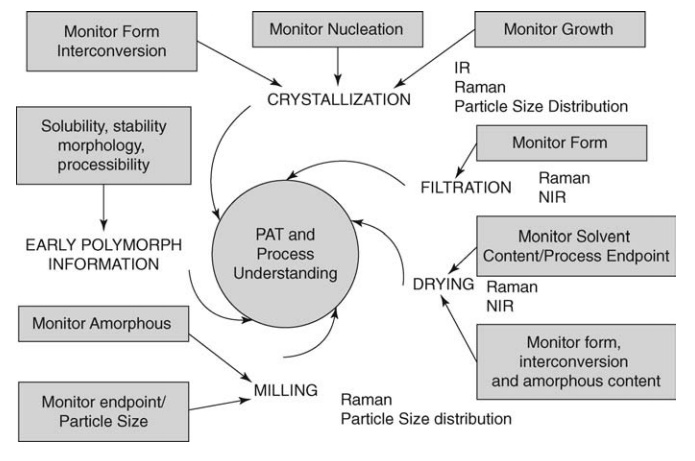

PAT

necessarily begins with the manufacture of active pharmaceutical ingredient

(API) and any additives and understanding their properties (Byrn et al., 2006;

Hlinak et al., 2006). Important methods in this context address the presence of

impurities (including moisture), degradation products (stability), component

compatibility, and crystallinity (polymorphism). Near infrared spectroscopy has

been applied in situ, real time to address the chemical com-position of API or

additive during manufacture (Mendendorp et al., 2006). Near infrared laser

Raman spectroscopy has been employed to monitor polymeriza-tion process

(Francisco et al., 2006). A variety of particle sizing methods can be employed,

but those that are in situ, real time employ laser scattering methods. Dosage

form manufacturing can be optimized by direct methods of monitoring the

variables involved in drying, mixing/blending (Portillo, et al., 2008),

gran-ulation (Papp et al., 2008), filling, compression (Askeli and Cetinkaya,

2008; Soh et al., 2007), and coating (Bose et al., 2006; Cogdill et al., 2007).

For more sophisticated dosage forms, compatibility with packaging components is

also required, but this is likely to have been considered during the

preliminary experimental design optimization steps.

PAT

arguably is at the intersection of design space (considered in chap. 18) and

control strategy, these being the major elements of QbD. These topics have been

described in Product Quality Lifecycle Implementation initiative of the

International Society for Pharmaceutical Engineering (Drennan, 2008). Topics of

interest in this initiative have been described in the Journal of

Pharmaceutical Innovation.

FIGURE 19.1

Critical steps in API manufacture. Source: Modified from Byrn et al. (2006).

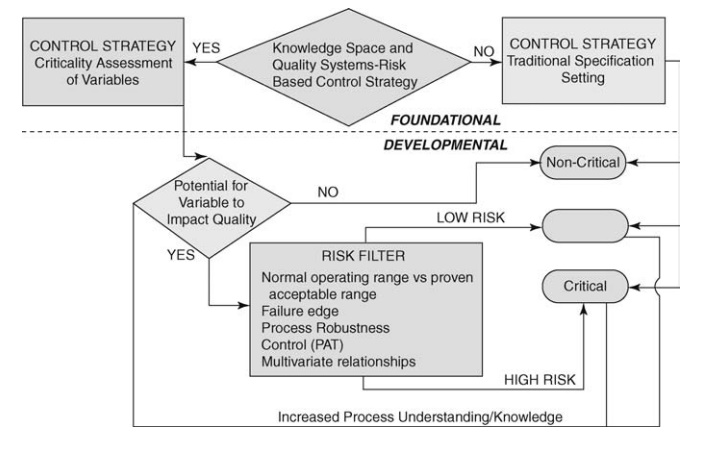

FIGURE 19.2 Decision tree to define levels of criticality. Source: Modified from

Garcia et al. (2008).

Figure

19.2 presents the most prominent decisions required to evaluate the criticality

of variables in process development. Decisions (diamonds) are made based on the

business decision in foundational classification (above dotted line), and risk

assessment in developmental classification (below dotted line) that pass

through a filter (rectangle) to criticality designations (rounded rectangle).

With respect to criticality, those variables that are not critical have not

been demonstrated to impact on safety or efficacy or factor into critical

quality attributes (CQA) as defined by ICH Q(8) R and consequently do not have

to be included in design space. Critical variables are those that are known to

impact safety, efficacy, or other measures of biological disposition or

com-pliance. Critical process parameters if varied beyond a certain range have

a direct and significant influence on CQAs. These properties must be controlled

within predesignated range to ensure final product quality. The empty symbol

represents an alternative designation for attributes that may impact the

product but represent a low risk. The designation of low risk is based on an

indirect impact on safety and/or efficacy alone or in combination with other

variables; mitigated risk; and knowledge transfer from noncritical variables

requiring additional evaluation.

It

has been suggested that criticality can be reduced to fundamental ele-ments of

severity, occurrence, and detection in a compounding manner (Nosal and Schultz,

2008). These terms can be related to experimental design (frequency and

variation) and analytical capability (detection). During the life cycle of the

product clear differentiation of levels of criticality is required to address a

control strategy based on process variables, material attributes, and their

relationship to quality measures.

Related Topics