Dressings

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Sterile Pharmaceutical Products

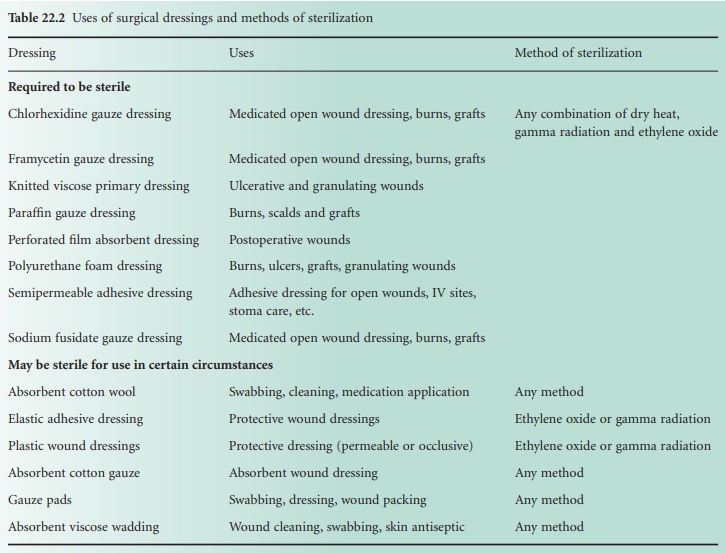

Dressings and surgical materials are used widely in medicine, both as a means of protecting and providing comfort for wounds and for many associated activities such as cleaning and swabbing. They may or may not be used on areas of broken skin.

DRESSINGS

Dressings and surgical materials are

used widely in medicine, both as a means of protecting and providing comfort

for wounds and for many associated activities such as cleaning and swabbing.

They may or may not be used on areas of broken skin. If there is a potential

danger of infection arising from the use of a dressing then it must be sterile.

For instance, sterile dressings must be used on all open wounds, both surgical

and traumatic, on burns, and during and after catheterization at a site of

injection. It is also important to appreciate that sterile dressings must be

packaged in such a way that they can be applied to the wound aseptically.

Dressings are described in the British Pharmacopoeia (2010). Methods for their

sterilization include autoclaving, dry heat, ethylene oxide and ionizing

radiation. Any other effective method may be used. The choice is governed

principally by the stability of the dressing constituents to the stress applied

and the nature of their components. Most celluloses and synthetic fibres

withstand autoclaving, but there are exceptions. For instance, boric acid

tenderizes cellulose fibres during autoclaving, and dressings containing waxes

cannot be sterilized by moist heat. Certain constituents are also adversely

affected on exposure to large doses of gamma radiation. Examples of dressings

that are required to be sterile are listed in Table 22.2,

together with other dressings and materials that may be sterilized when

required.

A very important aspect of the production of dressings

is packaging. The packaging material must allow correct sterilization conditions (e.g.

permeation of moisture

or ethylene oxide), retain

the dressing in a sterile

condition and allow for its removal

without contamination prior

to use. All dressings intended

for aseptic handling

and application must be double

wrapped. For steam

sterilization they may be individually wrapped in fabric,

paper or nylon and sterilized in metal drums,

cardboard boxes or bleached Kraft paper. The choice of method also determines the design of the autoclave cycle. Providing that adequate steam penetration is assured, dressings may be sterilized in downward

displacement autoclaves which rely on displacement of air by steam. However, high

prevacuum autoclaves in which virtually all the air is removed before the admission of steam are much more commonly

employed. This method

ensures rapid heating

up of dressings, reduces the time needed

to achieve sterilization (e.g. 134 °C for 4 minutes) and shortens the overall sterilization cycle.

A recent

development is the use of spray-on dressings. A convenient type is an acrylic polymer

dissolved in ethyl acetate and packed as an aerosol.

This should be self-sterilizing. The

film after application is able to maintain the sterility of a clean wound for up to 2 weeks. However, they can only be used on clean,

relatively dry wounds.

Related Topics