Quality Control and Quality Assurance

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Sterile Pharmaceutical Products

It is not the aim of this section to review the entirety of quality control of sterile products or of the chemical assays and requirements of drugs and excipients prior to formulation. Only those techniques with importance either to microbiology or the confirmation of sterility of the final product are introduced here.

QUALITY CONTROL AND QUALITY

ASSURANCE

It is not the

aim of this

section to review

the entirety of quality control of sterile

products or of the chemical assays and requirements of drugs and excipients prior to

formulation. Only those

techniques with importance either to microbiology or the confirmation of sterility of the final product

are introduced here.

A) Bioburden

It should

be obvious from

previous sections that a successful sterilization process is dependent on a product having a low presterilization bioburden. This will

also be true of the individual ingredients, which must

have low levels of microbial contamination, or else there is a

danger that

the contaminants will

find their way into the final product or be a source

of pyrogens.

Sterilization should

normally be considered as the removal of the bioburden, but the high heat resistance of bacterial endotoxins means that successful steam sterilization does not necessarily guarantee

that the product will pass a pharmacopoeial endotoxin

test; dead bacteria are likely to remain pyrogenic.

Underestimating the

level of microbial contamination prior to the terminal sterilization process will lead to a miscalculation of the sterilization dose requirements to achieve the desired SAL.

The bioburden must

be maintained within certain

limits to justify

the chosen sterilization process. When a higher

number of organisms or more

resistant microorganisms are encountered during manufacture of batches than was determined during the initial validation, those

batches must be assumed not to

be sterile. The bioburden is an estimate

of the total

viable count of microorganisms present

before sterilization, and a knowledge of the resistance characteristics

of these organisms is often an integral part

of the sterility assurance calculation. To build

some degree of safety into

the sterilization process

the sterilization conditions should be set to destroy

all the bioburden by assuming that all the

contaminating

microorganisms are the most resistant of the species identified in that bioburden. Sterility assurance, as implied

in the schemes shown in Figures 22.1 and

22.2, can only be achieved with

a low bioburden and with fully validated, correctly functioning sterilizers.

B) The Test For Sterility

The broad

basis of the test for sterility is that it examines

samples of the final product

for the presence of microorganisms.

Theoretically, the test for sterility should

be applied to all products that are designated as sterile. However, the test does not examine

all samples in a batch, and its results

can only be considered valid

if all items in a batch

are treated similarly (British

Pharmacopoeia, 2010). Clearly,

for products which are terminally sterilized this might

seem a reasonable assumption but only if

there is uniform

heat distribution in an autoclave

or hot air oven

or uniform delivery

of a radiation dose. With

aseptically produced

products there are dangers because not all items

in a batch may have been treated

similarly. A successful test

only shows that

no microbial contamination was found in the samples

examined under the test

conditions. Extension of the result

to a whole batch

requires the assurance that every

unit in the

batch was manufactured in such a manner that it would

also have passed the test with a high degree of probability. This highlights the weakness of the test

for sterility and why

the controls

of sterilization processes

are very important and probably of greater assurance in confirming the

sterility of a batch.

The test, however, remains

one of few analytical methods that examine a product for sterility.

C) Parametric Release

As there are significant limitations with the test for sterility, many authorities place

considerable reliance on the

validation and reliable performance of sterilizers and their sterilization cycles.

Parametric release takes

this reliance a step further by allowing batches

of terminally sterilized products to be released

without being subjected to the test

for sterility. The sterilization cycle

will be validated to have a SAL of 10−6 or less as the minimum

safety factor. Validation studies would include

heat distribution, heat penetration, bioburden, container closure

and cycle lethality studies.

For a product to be subject to parametric

release, presterilization bioburden testing on each batch

would be completed, and the comparative resistance of isolated spore-formers checked. Each cycle would

include the use of chemical

or biological indicators. It is hoped that these actions will provide a significantly higher

level of assurance of sterility than provided by the test for

sterility. This

requires confirmation that

each part of the

manufacturing process

has been satisfactorily completed, the initial presterilization bioburden is within agreed limits, that

the controls for the sterilizing cycle were satisfactory and that the correct time

cycles were achieved. In practice parametric release

should only be used when experience has been gained

on a reliably controlled and adequately validated process

and where a relationship has been

proved between end-product testing and in-process monitoring.

Clearly,

reproducibility,

regular monitoring and documentation are required. However, parametric

release would imply abandoning the sterility test,

an option that many manufacturers have not yet

adopted, possibly because of the fear of litigation based

on the premise that any sterile

product would, if tested, have

passed the test for sterility.

D) Pyrogens

The discovery that

aqueous solutions may lead to an increase in body temperature when injected into a patient dates back to the 19th century. The agents responsible for this fever

were termed ‘pyrogens’. In theory a pyrogen is any substance that, when injected

into a mammal, elicits a rise in body temperature, and substances produced

by some Gram-positive bacteria, mycobacteria, fungi and also viruses conform

to this definition. The most common

pyrogens, however, and those of major significance to the

pharmaceutical industry, are produced by Gram-negative

bacteria and are known

as endotoxins; they are lipopolysaccharides (LPS)

found in the

cell envelope . The

presence of pyrogens in aqueous solutions was first

demonstrated by injection into rabbits whose

body temperature was recorded. More sensitive methods have since been developed, mostly based on the discovery that a fraction of the horseshoe crab blood reacts

with LPS as a

clotting agent.

Two pharmacopoeial

limit tests exist.

That for pyrogens uses rabbits to assess pharmacological

activity and therefore the presence of pyrogens of all kinds.

The test for bacterial endotoxins uses lysed

amoebocytes (blood cells) of the horseshoe crab and is therefore termed

the Limulus amoebocyte lysate (LAL) test. This may be extended to many drug and device products

and clearly will be developed in the future

to assess the

presence of endotoxins in biotechnology products.

i) Physiological effects of pyrogens

The most characteristic

effect following injection of pyrogens into humans

is a rise of body

temperature, but it is only one of a number

of dose-dependent diverse effects. Pyrogens elevate

the circulating levels

of inflammatory cytokines, which may be followed by fever,

blood coagulation,

hypotension, lymphopenia, neutrophilia, elevated levels of plasma cortisol and acute-phase proteins. Low doses of pyrogens induce asymptomatic inflammatory reactions. Moderate doses induce

fever and changes in plasma composition. Injection of high pyrogenic doses results in shock, characterized by cardiovascular dysfunction, vasodilation,

vasoconstriction, endothelium dysfunction and multiple

organ dysfunction or failure and death.

ii) Characteristics of bacterial endotoxin

The release of LPS from

bacteria takes place

after death and lysis. Many

Gram-negative bacteria, e.g. Escherichia coli and Proteus,

Pseudomonas, Enterobacter and Klebsiella species produce pyrogenic LPS which is composed of two

main parts: a hydrophilic polysaccharide chain with antigenic regions, and

a hydrophobic lipid

group termed lipid A which is responsible for many of the biological activities. The molecular

size of the polysaccharide chain is very variable, and consequently the molecular weight of the LPS may vary from a few thousand

to several million daltons. LPS

is unusually thermostable and in sensitive to pH changes. Molecules are able to withstand 120 °C for over

3 hours. Extremes of pH are required for rapid destruction of the LPS.

iii)

Sources

The sources

of pyrogens in parenteral products include water used at the end

stages of the purification and

crystallization of the drug or excipients; water

used during processing; packaging components; and the

chemicals, raw materials

or equipment used in the preparation of the

product. The presence of endotoxins on devices may be

attributed to water

in the manufacturing process, the washing of components such as filter

media to be used

for the manufacture of filters, or the washing/rinsing of tubing or other

plastic devices prior

to their sterilization. Additionally, if the drug is biologically produced, incomplete removal of the microorganisms during purification

can result

in high endotoxin levels.

iv)

Measurement of pyrogens

Pyrogens have

traditionally been assessed using rabbits which are stored in carefully

controlled conditions and whose

temperature is monitored before the administration of the test product.

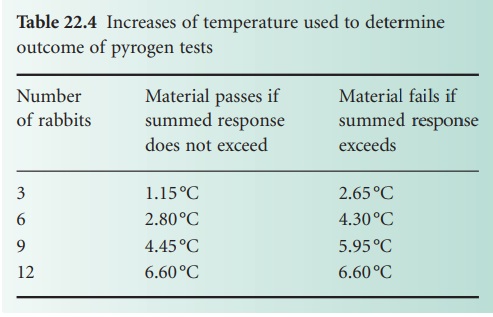

The British Pharmacopoeia (2010) describes a test initially

based on three rabbits;

the number is progressively increased if the results

fall between the two values (Table 22.4). Samples

of the product under test are injected

into the marginal

ear vein at a dose no greater than

10 ml/kg. The animals are monitored for the 3 hour period immediately after injection, at 30 minute intervals. The test assumes that

the maximum rise in temperature will be detected

in this 3 hour

period immediately after injection. Table 22.4 describes the criteria for pass or fail as the number

of rabbits used increases to the maximum

of 12.

A number

of limitations of the rabbit

pyrogen test are recognized. Repeated use of animals leads

to endotoxin tolerance. There is low reactivity to the endotoxin produced by certain

species, e.g. Legionella. There

is also variability

in control results

when identical standardized endotoxin preparations are used, which is

probably related to interlaboratory factors and variations due to seasons, rabbit species

and other biological sources. Care must be taken in testing radiopharmaceuticals,

and certain drugs

may themselves elicit

a rise in temperature on administration. The test is therefore inadequate for radiopharmaceuticals,

cancer chemotherapeutic agents, hypnotics and narcotics, vitamins, steroids and some

antibiotics. The presence of pyrogens may be hidden

by the pharmacological activity of the product’s components. Finally the rabbit test is insufficiently sensitive to detect endotoxin in intrathecal products

where only low levels of pyrogens

are acceptable.

EMA (2009)

is to encourage the replacement of the rabbit test with

the monocyte activation test (Hoffmann,

2005) for plasma-derived medicinal products.

Human monocytes from cultured

cell lines mimic the human fever reaction in vitro

by producing cytokines. Cytokine release can be determined, usually using enzyme-linked immunoassay (ELISA).

v)

Measurement of bacterial endotoxins

The LAL test is considerably more

sensitive than the pyrogen test. As mentioned above,

although the Legionella

endotoxin is not very pyrogenic to rabbits it is easily detected by the LAL test.

It has been

estimated that there is a 1000-fold difference in sensitivity between

the two tests, but the LAL test only

detects endotoxins of Gramnegative bacteria

and not all pyrogens. However, the LAL

test may be used

for radiopharmaceuticals.

LAL test reagent

comes from the American horseshoe crab Limulus

polyphemus. The endotoxin-induced coagulation of its blood is based on an enzyme-mediated interaction

of LAL with endotoxins. The reagents are obtained from the blood of freshly captured

horseshoe crabs whose

amoebocytes are concentrated, washed

and lysed with endotoxin-free water. The LAL is separated

from the remaining cellular debris and its activity optimized

using metallic cations, pH adjustment and

additives and then

freeze-dried. Certain preparations interfere with the interaction between LAL and endotoxin. Chemical

inhibitors may cause chelation of the

divalent cations necessary for the reaction, protein denaturation

or inappropriate pH changes. Physical inhibition may result from adsorption of endotoxin or be caused by viscosity of the product.

Even the type of glassware may affect the test. Siliconized glassware or plastic can

inhibit gel-clot formation, or prevent accurate spectrophotometric readings of the reaction

end-point.

The samples

of products are incubated with LAL at 37 °C. If endotoxins are

present a solid

gel forms, indicating the presence

of endotoxins. The British Pharmacopoeia

(2010) describes six

separate methodologies for

the test for endotoxin. These

are (A) gel-clot

limit test; (B) gelclot: semi quantitative; (C) turbidimetric

kinetic method; (D) chromogenic

kinetic method; (E)

chromogenic endpoint method;

and (F) turbidimetric end-point method.

There are checks for interfering factors. Any validated

method may be used, but the gel-clot

method is the referee test in the case of dispute. Coloured products cannot be tested

by turbidimetric and chromogenic

methods, as precipitate formation may be mistaken for a

positive response.

Kinetic LAL methods are claimed to increase the efficiency of large-scale testing,

probably important when validation of depyrogenation cycles

or preparation of components for aseptic

processing are required. For all procedures, test validation must be conducted to rule out interference, which may be either

inhibition or enhancement. Depyrogenated glassware must be

used throughout.

The gel-clot method

is most commonly used. The test is conducted by adding the LAL reagent

to an equal volume of test

solution, agitating and storing at 37 °C for

1 hour when

the end-point is determined by inversion

of the tubes. If a solid clot remains intact,

the product is considered to contain endotoxins.

Chromogenic methods utilize

colorimetry but do not depend

on the clottable protein. A synthetic substrate

is used that contains an amino

acid sequence similar

to that of coagulogen, the clottable

protein. The activated

proclotting enzyme cleaves

a p-nitroanilide chromophore from the

synthetic substrate and the colour

produced is proportional to the amount of endotoxin. The turbidimetric

LAL method is based on the fact

that an increase in endotoxin concentration will cause a proportional increase

in turbidity caused

by the precipitation of the clottable protein, coagulogen. The optical density

is read spectrophotometrically either at a fixed time or constantly for kinetic assays

as turbidity develops. The kinetic methods depend on the

relationship between the logarithm of the

response and the logarithm of the endotoxin concentration. The end-point

methods relate endotoxin

levels to the quantity

of chromophore released

or the amount

of precipitation.

vi)

Endotoxins in

parenteral Pharmaceuticals

The limits

for endotoxin are based on the dose

of the product. Put simply, the endotoxin limit,

EL, which represents the maximum amount of endotoxin that is allowed in a specific dose,

is inversely related

to the dose of

the drug; it may be assessed from

the following equation (United States Pharmacopeia, 2010):

EL = K/M (2)

where K is

the threshold human

pyrogenic dose of endotoxin per kg body

weight and M is

the maximum human dose of the product in kg body weight that would be administered

in a single 1 hour

period. M recognizes that the pharmacological effects of endotoxin are

dosedependent. The endotoxin limit is the

level at which

a product is

adjudged pyrogenic or non-pyrogenic. Gelclot reagent sensitivities are generally in the range

0.015–0.5 EU/ml. As examples of endotoxin limits,

the United States Pharmacopeia (2010) states limits

of no more than 0.5 EU/ml for Dextrose Infusion, no more than 5 EU/mg promethazine in Promethazine Injection

USP, no more than 10 EU/mg of mitomycin in Mitomycin for

Injection USP and no more than 24 EU/mg warfarin

sodium in Warfarin Sodium for Injection. The British Pharmacopoeia

(2010) has a limit

of 0.25 IU/ml

in Glucose Intravenous Infusion; this

value is similar

for many BP intravenous

infusions. As another example,

insulin should contain

no more than 10 IU/mg

of endotoxin. The endotoxin limit for drugs gaining

access to the cerebrospinal fluid

is reduced to 0.2 EU/kg

because the intrathecal route is the most toxic route for endotoxins.

vii)

Depyrogenation and the

Production of Apyrogenic Products

Pyrogens and endotoxins

are difficult to remove from products once present

and it is easier to keep components relatively endotoxin-free rather than to remove them from the final product.

Rinsing or dilution is one way of

eliminating pyrogenic activity provided that the rinsing

fluid is apyrogenic. Closures

and vials should be washed with pyrogen-free water

before sterilization. Pyrogens in vials or glass

components may be destroyed by dry heat sterilization at high temperatures. A

recommended condition for depyrogenation of glassware and equipment is heating at 250 °C for 45 minutes.

Pyrogens are also destroyed at 650 °C in 1 minute

or at 180 °C in 4 hours. The British Pharmacopoeia (2010) states that dry heat at

temperatures above 220

°C may be used for

the depyrogenation of glassware. Sterilizing tunnels are designed

not only to sterilize at 250–300 °C but also

to remove pyrogens. These processes equate to incineration, although removal by

washing, also termed dilution, may be used. Filtration, irradiation or ethylene oxide treatment have limited

value in reducing pyrogen or endotoxin loads.

The removal

of pyrogens from

Water for Injections may be effected by distillation or reverse osmosis. Distillation is the most reliable method for removing endotoxin. Care

has to be taken to avoid splashing in the still as pyrogens have been carried

over in droplets. Another source

of endotoxins is the Water for Injection system. Generally, circulating hot water at temperatures above 75 °C provides

an environment that is

not conducive to microbial growth

and thus the formation

of endotoxin. Circulating water at approximately 60 °C causes some concern

as some Gram-negative organisms, e.g. Legionella

pneumophila, will survive and grow at 57 °C. The water-producing systems

may be sanitized by circulating water at 75–80

°C.

Pyrogen-free water

can be produced using an ultrafiltration membrane with a nominal

molecular weight limit that

is low enough to ensure the removal of endotoxins under all conditions. Hollow

fibre polysulphone membranes can be sanitized

with sodium hydroxide, which efficiently destroys pyrogens. A nominal

molecular weight limit of 5000 Da should efficiently

remove endotoxins. However, many endotoxin-producing

microorganisms multiply in ambient temperature Water for Injection systems, especially reverse osmosis (RO) systems, in which the filters

are not absolute

and may be used in series in order to manufacture pyrogenfree water.

Related Topics