Definitions

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Principles Of Good Manufacturing Practice

Several terms used in industrial and hospital production must be defined to enable the reader to follow this article.

DEFINITIONS

Several terms used in industrial and

hospital production must be defined to enable the reader to follow this article.

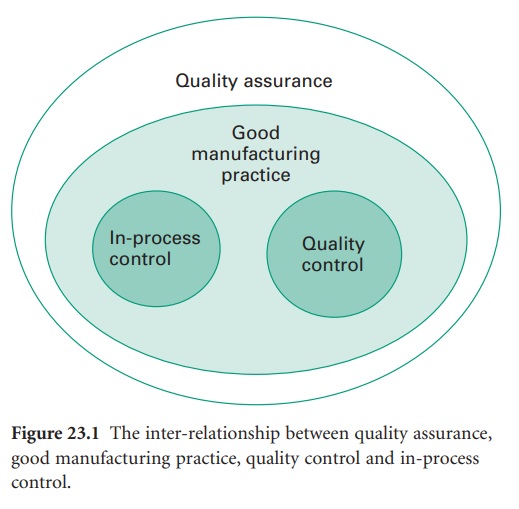

The inter-relationship between quality assurance (QA), GMP, quality control

(QC) and in-process control is shown in Figure 23.1.

The UK Orange Guide (The Rules and Guidance for Pharmaceutical Manufacturers and

Distributors, 2007) emphasizes the fundamental point:

Quality assurance is particularly important, and this type of manufacture

must strictly follow carefully established and validated methods of preparation

and procedure. Sole reliance for sterility or other quality aspects must not be

placed on any terminal sterilization process or finished product test.

The difficulty in demonstrating quality

is that the tests carried out are designed to show the absence of quality. For

example, the test for sterility involves taking samples and testing for

microorganisms. If 20 samples are tested, 3.4% of the batch needs to be

contaminated to have a 50% chance of detecting that contamination. That level

of contamination represents gross failure of GMP and problems would normally be

detected by environmental monitoring. Indeed, it is not unknown for a batch to

pass a sterility test but be rejected due to problems detected during

environmental monitoring (section 5.2). Therefore it is important that a

product be manufactured in a suitable environment by a procedure that minimizes

the possibility of contamination occurring. At the end of this process the

tests can be performed as an additional measure

of quality.

A) Quality

There are many definitions of quality (see Sharp, 2000). For the purpose of

pharmaceutical products the term quality is

usually taken to mean fitness for purpose.

Not only must the product have the desired therapeutic properties, it must also

be safe for administration by the route intended. Sharp (2000, 2001) discussed

several meanings of quality but summarizes it as follows:

in a nutshell, it is fit to be given to a patient in the confidence that

it will have the desired effects and not damage him or her, in any way, through

faults in manufacture.

B) Manufacture

Manufacture is the complete cycle of production of a medical product.

This cycle includes the acquisition of all raw materials, their processing into

a final product, and subsequent packaging and distribution.

C) Quality Assurance (QA)

Quality assurance is a wide ranging concept covering all matters which

individually or collectively influence the quality of a product. It is the

total sum of the procedures needed to ensure the fitness of a pharmaceutical

product for its intended use. QA incorporates GMP plus other factors.

D) Good Manufacturing Practice (GMP)

GMP is that part of QA which is aimed at ensuring the product is

consistently manufactured to a quality appropriate for its intended use and to

meet the requirements of the regulatory authorities. GMP requires that: (1) the

manufacturing process is fully defined before it begins; and (2) the necessary

facilities are provided. In practice, this means that:

·

Personnel must be adequately trained..

·

Suitable premises and equipment must be

employed.

·

Correct materials must be used.

·

Approved procedures must be adopted.

·

Suitable storage and transport

facilities must be available.

·

Appropriate records must be made.

The reasons for GMP are (Sharp, 2001):

·

the poor chance of the patient

detecting that anything is wrong

·

the weakness of product testing

because:

·

we can only test samples

·

we cannot test for everything

·

the dangers to patients of even only a

small number of defective or wrongly labelled items in a batch (and it is very

difficult to detect a small number of defectives).

It is about getting things right all along the line.

E) Quality Control (QC)

QC is that part of GMP concerned with

sampling, specifications and testing, as well as the organization,

documentation and release procedures which ensure that the necessary and relevant

tests are carried out, and that materials are not released for use, nor

products released for sale or supply, until their quality has been judged

satisfactory. For sterile products QC includes testing for sterility and

pyrogens. The Rules and Guidance for Pharmaceutical Manufacturers and

Distributors (2007) states that QC is not confined to

laboratory operations, but must be involved in all decisions which may affect

the quality of the product. The independence of QC from production is

considered fundamental to the satisfactory operation of QC.

F) In-Process Control

This comprises any test on a product, the environment or the equipment

that is used during the manufacturing process. An example of this is testing

that an autoclave is functioning correctly (Gardner & Peel, 1998).

G) Validation

A documented programme that provides a high degree of assurance that a

specific process, method or system will consistently produce a result meeting

predetermined acceptance criteria.

Related Topics