Packing and Labelling of Drug Formulations

| Home | | Forensic Pharmacy |Chapter: Forensic Pharmacy : The Drugs and Cosmetics Act (DCA) 1940 and Rules 1945

Different steps in the manufacturing of drugs are suitably monitored by way of provisions made under DCA and Rules.

Packing and Labelling of Drug

Formulations

Different steps in

the manufacturing of drugs are suitably monitored by way of provisions made

under DCA and Rules. The stages involved from procurement of raw material to

the sale of drug formulations at the retail counters are mandatorily controlled

in accordance with the provisions of the Act. In addition to mandatory

requirement, it is also the moral, ethical and social responsibility of the

manufacturer to ensure that the consumer receives good quality of his/her

products. Packing is a blend of art and science with regulatory flavour. It is

not sufficient to provide artistic packaging of the formulations but, it should

be sufficient enough to ensure the stability of product during transportation

and storage, assuring high quality of the product.

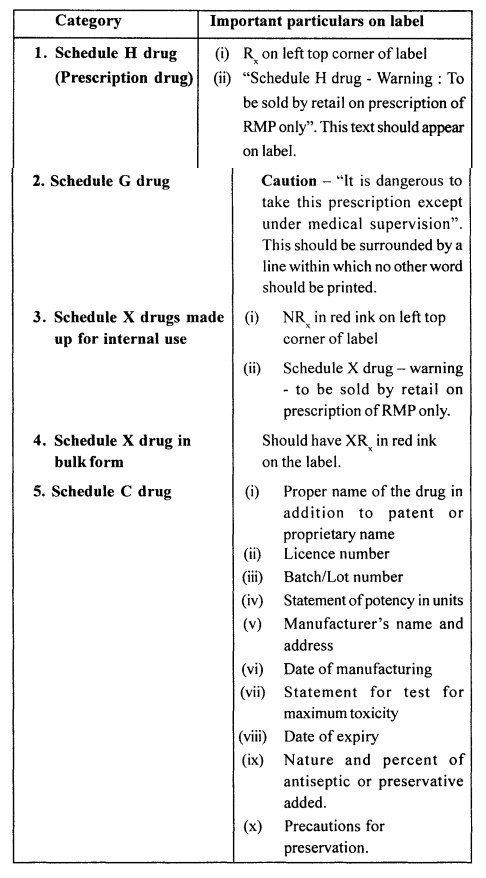

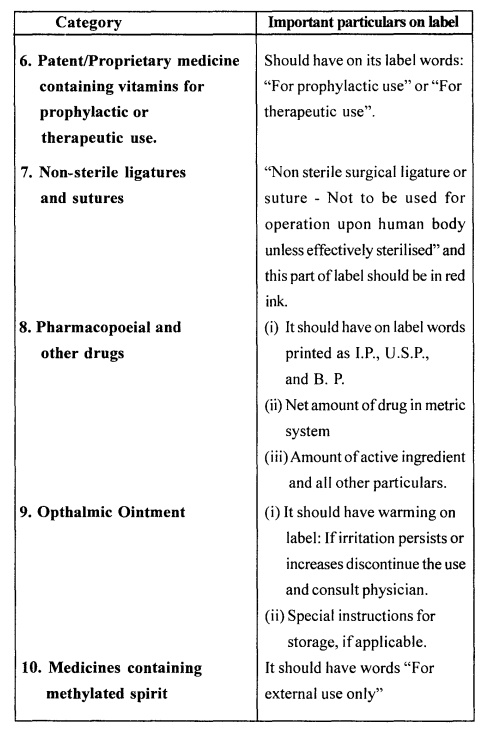

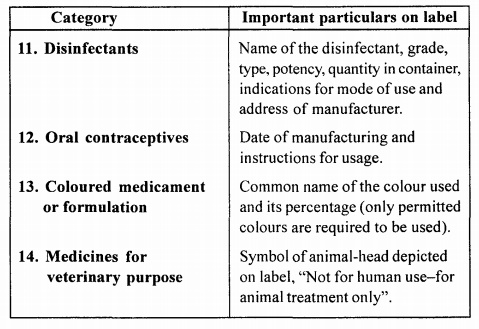

The

text of labelling on packing material varies with the type of product

formulated. There are specific requirements of labelling for drugs of Schedules

G, H and X; external

applications, patent and proprietary medicines, opthalmic ointments,

contraceptives, disinfectants and several other drug formulations.

Labelling

should be attractive and readable. It should be in printed form on the

outerside of the packing material, as well as, on the packing of drug

formulation. Even single unit offormulation (ampoule or tablet) should have

appropriate label on it. In case of single dose of tablet, it could be short

name of the product embossed on it.

The following

particulars should appear in the label of the drug formulation.

1.

Name (Patent or Proprietary and Generic name)

2.

Name and address of manufacturer

3.

Batch or lot number

4.

Date of manufacturing

5.

Expiry date, if any

6.

Information for storage, if any

7.

Precautionary information - i.e., care in handling the

product, use, etc.

8.

General information including - Physicians sample - not to

be sold, in case of, physicians.

In case of medicines

made up ready for treatment, name and address of licensee by whom it is

"Supplied should appear on the label.

In case of

preparations included in B.P, B.P.C, I.P the abbreviations should be mentioned.

In

a preparatron containing more than 3% alcohol, the percentage of alcohol should

be mentioned on the label.

Particulars of Label

The label should be

printed or written in indelible ink and should clearly appear on label of inner

most container and every other covering of the container. The details of

labelling include-

1. Name ofthe drug

(Trade name/Generic name as applicable) should be printed clearly.

2. Net contents (weight, measure, volume or number of units

of activity as applicable). Net content should be in metric system.

3. Contents of active ingredients:

(a) For solid oral

dosage forms (tablet, capsule), content in each unit of formulation.

(b) Solid form for injectables, in terms of weight mg/gm of

powder. In case antibiotic, it is in terms of units of activity.

(c) Liquid orals: contents of ingredients in single dose of5

ml or multiple. If dose is less, the contents of ingredients in 1 ml of

preparation.

(d) Liquid parentral

preparation: contents of ingredients in I ml or per dose in case of single dose

preparation.

4.

Name and address of the manufacturer on small container. Name and place of

manufacture is sufficient on each ampoule

5. Manufacturing licence number abbreviated as Mfg. Lic. No.

6. Distinctive Batch No. should be written as Batch No. or

B.No. or Batch, Lot No.

7. Date of manufacturing.

8. Expiry particulars, ifany.

9. Precautions related to handling, use or distribution.

10. Information on storage.

11. Any other general information or specific information

pertaining to formulation. If the sample is for physician, the words

"Physicians sample - not for sale" should be printed.

For

Schedules F and F (I) and X drugs, only

Code No. as approved by the Licensing Authority is required to be printed.

Related Topics