Sterility Testing

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Sterilization Procedures And Sterility Assurance

A sterility test is essentially a test which assesses whether a sterilized pharmaceutical or medical product is free from contaminating microorganisms by incubation of either the whole or a part of that product with a nutrient medium.

STERILITY TESTING

A sterility

test is essentially a test which assesses whether a sterilized pharmaceutical or medical product

is free from contaminating

microorganisms by incubation of

either the whole or a part of that product

with a nutrient medium. It thus

becomes a destructive test and is of

questionable suitability for testing large,

expensive or delicate products or equipment. Furthermore, by its very nature such a test is a statistical process in which

part of a batch is sampled and the chance

of the batch being passed for use then depends

on the sample passing the sterility test. Random sampling

should be applied to products that have been processed and filled aseptically. With products

sterilized in their

final containers, samples should be taken from the potentially coolest

or least sterilant-accessible part of the load.

A further

limitation is that

which is inherent in a procedure intended to demonstrate a negative. A sterility test is intended to demonstrate that

no viable organisms are present, but failure

to detect them could simply

be a consequence

of the use of unsuitable media or inappropriate cultural conditions. To be certain that

no organisms are present

it would be necessary to use a universal culture medium suitable for

the growth of any possible

contaminant and to incubate

the sample under

an infinite variety of conditions. Clearly, no such medium

or combination of media are available and, in practice, only media capable of supporting non-fastidious bacteria,

yeasts and moulds are employed. Furthermore, in pharmacopoeial tests,

no attempt is made to detect viruses,

which on a size basis, are the organisms most likely to pass through

a sterilizing filter. Nevertheless,

the sterility test

does have an important application in monitoring the

microbiological quality

of filter-sterilized, aseptically filled products and does offer a final check

on terminally sterilized articles. In the UK, test procedures laid down by the European

Pharmacopoeia

must be followed; this provides details

of the sample sizes to be adopted

in particular cases. The

principles of these tests

are discussed below.

a)

Methods

Three alternative methods are available when conducting sterility tests:

•

The direct inoculation method involves introducing test samples

directly into nutrient media. The European

Pharmacopoeia recommends two media:

(1) fluid mercaptoacetate medium (also known as fluid thioglycollate medium), which

contains glucose and

sodium mercaptoacetate

(sodium thioglycollate) and is particularly suitable for the cultivation of anaerobic

organisms (incubation

temperature 30–35 °C); and (2) soyabean casein digest medium (also known as tryptone

soya broth), which will support the growth of both aerobic bacteria (incubation temperature 30–35 °C) and fungi

(incubation temperature 20–25

°C). Other media

may be used provided that they can

be shown to be suitable alternatives. Limits are

placed upon the

ratio of the weight

or volume of added sample

relative to the volume of culture medium so as to avoid

reducing the nutrient properties of the

medium or creating unfavourably high osmotic pressures within it.

•

Membrane filtration is the

technique recommended by most pharmacopoeias and, consequently,

the method by which the

great majority of products are examined. It

involves filtration of fluids through

a sterile membrane filter (pore size ≤0.45

μm), any microorganism present being retained on the surface

of the filter. After

washing in situ, the filter is divided

aseptically and portions

are transferred to suitable culture media which are then incubated at the appropriate temperature for the required period of time.

Water-soluble solids

can be dissolved in a suitable diluent and processed in this way and oil-soluble products may be dissolved in a suitable

solvent, e.g. isopropyl myristate.

•

A sensitive

method for detecting low levels of contamination in intravenous infusion fluids involves

the addition of a concentrated culture

medium to the fluid in its

original container, such that the

resultant mixture is equivalent to single strength culture

medium. In this way, sampling of the entire volume

is achieved.

With the techniques

discussed above, the media employed should previously have been

assessed for nutritive (growth-supporting) properties and a lack

of toxicity using specified organisms. It must

be remembered that any survivors of a sterilization process

may be damaged and thus must be given

the best possible

conditions for growth.

As a precaution against

accidental contamination, product testing must

be carried out

under conditions of strict asepsis using,

for example, a laminar airflow

cabinet to provide

a suitable environment.

The European Pharmacopoeia indicates that it is necessary to conduct

control tests that

confirm the adequacy of the facilities by sampling of air and surfaces and carrying out tests using

samples ‘known’ to be sterile

(negative controls). In reality, this means samples

that have been subjected to a very reliable sterilization process, e.g. radiation, or samples that have been subjected to a sterilization procedure more

than once. In order to minimize

the risk of introducing contaminants from the surroundings or from

the operator during

the test itself,

isolators are

often employed which physically separate the operator from the materials under test.

b) Antimicrobial Agents

Where an antimicrobial agent

comprises the product

or forms part of the product, for example as a preservative, its activity must be nullified in some way during sterility testing so that

an inhibitory action

in preventing the growth of any contaminating microorganisms is overcome. This is achieved by the following methods.

i) Specific inactivation

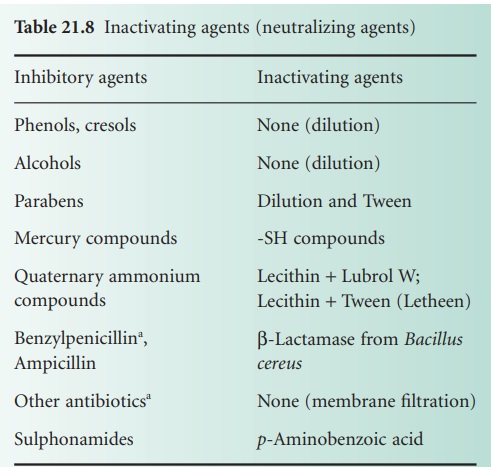

An appropriate inactivating (neutralizing) agent (Table 21.8) is incorporated into

the culture media.

The inactivating agent must be non-toxic to microorganisms, as must

any product resulting from an interaction of the inactivator

and the antimicrobial agent.

Although Table 21.8 lists only benzylpenicillin and ampicillin as being inactivated by β-lactamase (from

B. cereus), other β-lactams may also be hydrolysed by βlactamases. Other antibiotic-inactivating enzymes

are also known and have been considered as possible inactivating agents, e.g. chloramphenicol acetyltransferase (inactivates chloramphenicol) and enzymes that modify aminoglycoside antibiotics.

ii) Dilution

The antimicrobial agent is diluted

in the culture medium to a level at which it ceases

to have any activity, for example phenols, cresols and alcohols. This method applies

to substances with a high

dilution coefficient, η.

iii) Membrane filtration

This method

has traditionally been used to overcome the activity of antibiotics for which there

are no inactivating agents, although it could be extended to cover other products if necessary, e.g. those containing preservatives for which no specific or effective inactivators are available. Basically, a solution of the product

is filtered through a hydrophobic-edged membrane filter

that will retain

any contaminating

microorganisms. The membrane is washed in situ to

remove any traces

of antibiotic adhering to the membrane and is then

transferred to appropriate culture media.

c)

Positive Controls

It is essential to show that microorganisms will actually

grow under

the conditions of the test.

For this reason positive controls have to be carried

out; in these,

the ability of small numbers

of suitable microorganisms to grow in media

in the presence of the sample

is assessed. The microorganism used for positive control tests with

a product containing or comprising an antimicrobial agent must, if at all possible, be sensitive to that agent,

so that growth of the organism

indicates a satisfactory inactivation, dilution or removal of the agent.

The European Pharmacopoeia suggests the use of designated strains of Staphylococcus aureus, Bacillus subtilis and Pseudomonas aeruginosa as appropriate aerobic

organisms, Clostridium sporogenes as an anaerobe and Candida albicans or Aspergillus niger as fungi.

In practice, a positive control

(medium with added test sample) and a negative control

(medium without it) are inoculated simultaneously, and the rate and

extent of growth arising in each should be similar. However, the negative control

without the test sample,

is, in effect, exactly the same as the growth

promotion control that is also described in the test procedure, so, for

the organisms concerned, it is not necessary to do

both.

All the

controls may be conducted either

before, or in parallel with, the test itself,

providing that the same

batches of media are used for both.

If the controls are carried out in parallel with the tests

and one of the controls gives an unexpected result,

the test for sterility may be declared invalid,

and, when the problem is resolved,

the test may be repeated.

d) Specific Cases

Specific details

of the sterility testing of parenteral products, ophthalmic and other non-injectable

preparations, and surgical

sutures will be found in the European

Pharmacopoeia. These procedures cannot conveniently be applied to items like surgical dressings

and medical devices because

they are too big. In such cases

the most convenient approach

is to immerse the whole object in culture medium in a sterile flexible

bag, but care must be taken to ensure

that the liquid

penetrates to all parts and surfaces of the material.

e)

Sampling

A sterility test attempts to infer the state (sterile

or nonsterile) of a batch from the results of an examination of part of a batch,

and is thus

a statistical operation. Suppose that p represents the proportion of infected containers in a batch

and q the proportion of non-infected containers,

then, p +

q = 1 or q = 1 − p.

Suppose also

that a sample

of two items is taken

from a large

batch containing 10% contaminated containers. The probability of a single

item taken at random being contaminated is p = 0.1

(10% = 0.1), whereas the probability of such an item being

non-contaminated is given by q = 1 − p =

0.9. The probability of both items

being contaminated is p2 = 0.01, and of both items being non-contaminated, q2 = (1 − p)2 = 0.81. The probability

of obtaining one contaminated item and one non

contaminated item is 1 − (0.01 + 0.81) = 0.18 = 2pq.

In a sterility test

involving a sample

size of n containers, the probability p of

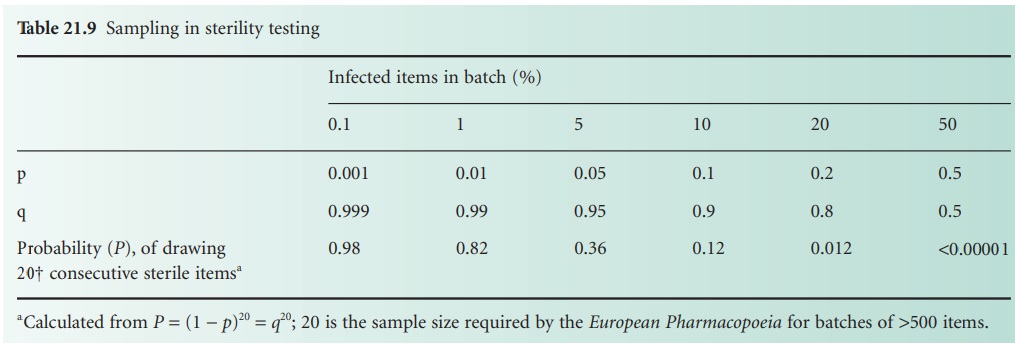

obtaining n consecutive ‘steriles’ is given by qn = (1 − p)n. Values for

various levels of p (i.e. proportion of infected containers in a batch)

with a constant sample size are given in Table 21.9, which shows that the test cannot

detect low levels

of contamination. Similarly, if different sample sizes are

employed (also based on (1 − p)n) it can be shown that

as the sample

size increases, the probability of the batch being passed

as sterile decreases.

It can be seen from the above that a sterility

test can only show

that a proportion of the

products in a batch is sterile. Thus, the correct

conclusion to be drawn from a

satisfactory test result

is that the batch has passed the sterility test not that the batch is sterile.

f)

Retests

Under certain circumstances a sterility test may be repeated, but the only justification for repeating the test

is unequivocal evidence

that the first

test was invalid;

a retest cannot be viewed as a second

opportunity for the batch to pass

when it has

failed the first

time. Circumstances that may justify

a retest would

include, for example, failure of the air filtration system in the testing facility which might have permitted

airborne contaminants to enter

the product or media during

testing, non-sterility of the media used

for testing, or evidence that

contamination arose during testing

from the operating

personnel or a source other

than the sample

under test.

Related Topics