Sterilization Control and Sterility

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Sterilization Procedures And Sterility Assurance

To be labelled ‘sterile’, a product must be free of viable microorganisms. To achieve this, the product, or its ingredients, must undergo a sterilization process of sufficient microbiocidal capacity to ensure a minimum level of sterility assurance.

STERILIZATION CONTROL

AND STERILITY

To be labelled ‘sterile’, a product must be free of viable microorganisms. To achieve

this, the product,

or its ingredients, must undergo a sterilization

process of sufficient microbiocidal capacity

to ensure a minimum level of

sterility assurance. It is essential that the required

conditions for sterilization be achieved and maintained

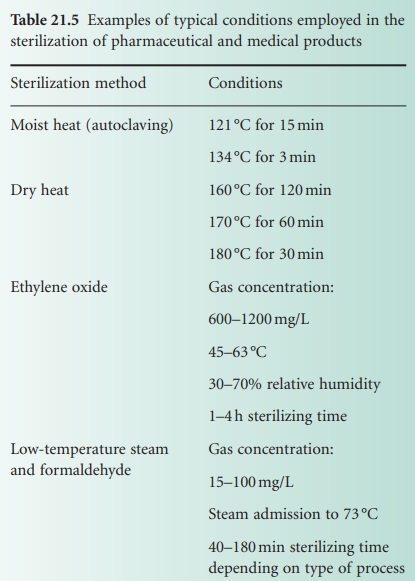

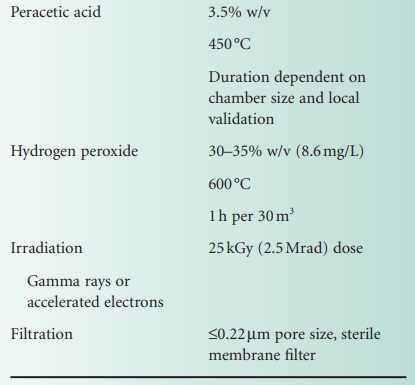

through every operation of the sterilizer. Some examples of typical conditions employed in sterilization are shown in Table 21.5.

Historically, the

quality control of sterile products consisted

largely, or in some

cases, even exclusively, of a

sterility test, to which the product was subjected at the

end of the manufacturing process.

However, a growing

awareness of the limitations of sterility tests

in terms of their ability to detect

low concentrations of microorganisms has resulted in a shift

in emphasis from a crucial dependence on end-testing to a situation in which the conferment of the status

‘sterile’ results from

the attainment of satisfactory quality

standards throughout the whole manufacturing process.

In other words, the quality is ‘assured’ by a combination of process monitoring and performance criteria; these may be considered under

four headings:

•

Bioburden determinations

•

Environmental monitoring

•

Validation and in-process monitoring of sterilization procedures

•

Sterility

testing.

In well-understood and well-characterized sterilization processes (e.g. heat and irradiation), where physical

measurements may be accurately made, sterility can be assured by ensuring that

the manufacturing process as a whole conforms to the established protocols for the first three of the above

headings. In this

case the process has satisfied the required parameters thereby permitting parametric release (i.e. release based on process

data) of the product without

recourse to a sterility test.

Related Topics