Batch Dryers

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Drying

Batch Dryers: Hot Air Ovens, Vacuum Tray Dryers, Tumbling Dryers, Fluidized Bed Dryers, Agitated Batch Dryers, Freeze-Drying

BATCH DRYERS

Hot Air Ovens

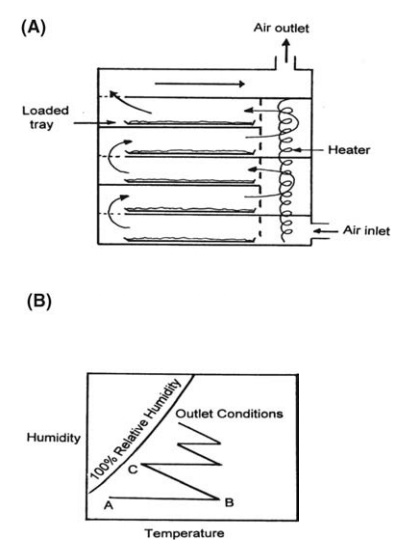

Ovens

operating by passing hot air over the surface of a wet solid that is spread

over trays arranged in racks provide the simplest and cheapest dryer. On small

installations, the air is passed over electrically heated elements and once

through the oven. Larger units may employ steam-heated, finned tubes, and

thermal efficiency is improved by recirculating the air. This is controlled by

manually set dampers, and a common operating position gives 90% recircula-tion

and 10% bleed-off. The heater bank is placed so that the solids do not receive

radiant heat and incoming air may be filtered. A typical hot air oven is

illustrated schematically in cross section in Figure 7.7A.

The

temperature-humidity sequence of the circulating drying air is pre-sented in

Figure 7.7B. The incoming air, at a temperature and humidity given by point A,

is heated at constant humidity to point B and passed over the wet solid. The

humidity rises and the temperature falls as the adiabatic cooling line is

followed until the air leaves the tray in condition C. It is then recirculated

to the heater, and in Figure 7.7B, two further cycles are shown.

FIGURE 7.7 (A) A tray dryer. (B) Temperature-humidity sequence of drying air.

We

have assumed that all heat is drawn from the air and transmitted across the

stationary air layer in contact with the drying surface, as described earlier.

Surface temperatures are, in fact, modified by heat absorbed and con-ducted

from unwetted surfaces, such as the underside of the tray, and by radiation.

The

chief advantage of the hot air oven, apart from its low initial cost, is its

versatility. With the exception of dusty solids, materials of almost any other

physical form may be dried. Thermostatically controlled air temperatures of

between 408C and 1208C permit heat-sensitive materials to

be dried. For small batches, a hot air oven is, therefore, often the plant of

choice. However, the following inherent limitations have led to the development

of other small dryers:

1. A large floor space is required for the oven and

tray-loading facilities.

2. Labor costs for loading and unloading the oven are high.

3. Long drying times, usually of the order of 24 hours, are

necessary.

4. Solvents can be recovered from the air only with

difficulty.

5. Unless carefully designed, nonuniform distribution of air

over the trays gives variation in temperature and drying times within the oven.

Variations of ±78C in temperature

have been found from location to location during the drying of tablet granules.

Poor air circulation may permit local saturation and the cessation of drying.

If

the material is of suitable granular form, drying times may be reduced to an

hour or less by passing the air downward through the material laid on mesh

trays. The oven in this form is called a batch through-circulation dryer.

Vacuum Tray Dryers

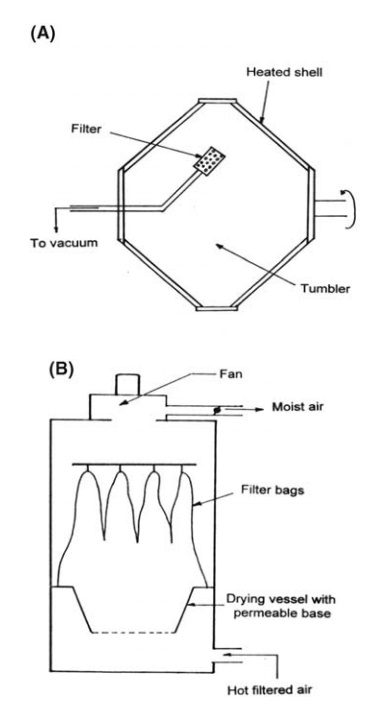

Vacuum

tray dryers, as shown in Figure 7.8A, differing only in size from the familiar

laboratory vacuum ovens, offer an alternative method for drying small

quantities of material. When scaled up, construction becomes massive to

FIGURE 7.8 (A) Rotary vacuum dryer and (B) fluidized bed dryer.

withstand

the applied vacuum, and cost is further increased by the associated vacuum

equipment. Vacuum tray dryers are, therefore, only used when a def-inite

advantage over the hot air oven is secured, such as low-temperature drying of

thermolabile materials or the recovery of solvents from the bed. The exclusion

of oxygen may also be advantageous or necessary in some operations.

Heat

is usually supplied by passing steam or hot water through hollow shelves.

Drying temperatures can be carefully controlled, and for the major part of the

drying cycle, the material remains at the boiling point of the wetting liquid

under the operating vacuum. Radiation from the shelf above may cause a significant

increase in temperature at the surface of the material if high drying

temperatures are used. Drying times are long and usually of the order of 12 to

48 hours.

Tumbling Dryers

The

limitations of ovens, particularly with respect to the long drying times, have,

where possible, promoted the design and application of other batch dryers. The

simplest of these is the tumble drier for which the most common shape is the

double cone shown in Figure 7.8A. Operating under vacuum, this provides

controlled low-temperature drying, the possibility of solvent recovery, and

increased rates of drying. Heat is supplied to the tumbling charge by contact

with the heated shell and by heat transfer through the vapor. Optimum

con-ditions are established experimentally by varying the vacuum, the

temperature, and, if the material passes through a sticky stage, the speed of

rotation. With correct operation, a uniform powder should be obtained as

distinct from the cakes produced when static beds are dried. Some materials,

such as waxy solids, cannot be dried by this method because the tumbling action

causes the material to aggregate into balls.

A

normal charge would be about 60% of the total volume, and for dryers 0.7 to 2 m

in diameter, drying times of 2 to 12 hours may be expected. In studying the

application of tumbler dryers to drying tablet granules, it was found that

periods of 2 to 4 hours replaced times of 18 to 24 hours obtained with hot air

ovens. The mixing and granulating capacity of the tumbling action has suggested

that these operations could precede drying in the same apparatus.

Fluidized Bed Dryers

The

term “fluidization” is applied to processes in which a loose, porous bed of

solids is converted to a fluid system having the properties of surface

leveling, flow, and pressure-depth relationships by passing the fluid up

through the bed.

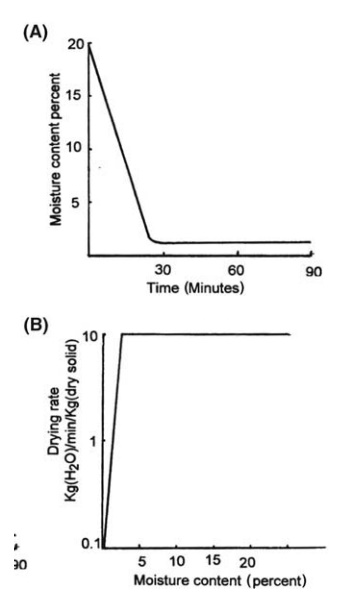

Fluidized

bed techniques, employing air as the fluidizing medium, have been successfully

applied to drying when the solid is of suitable physical form. The high

interfacial contact between drying air and solids gives drying rates 10 to 20

times greater than that obtained during tray drying. A drying curve for this

method is shown in Figure 7.9.

The

dryer, illustrated in Figure 7.8B, consists of a basket of either plastic or

stainless steel with a perforated bottom, which is mounted in the body of the

drier and into which the material to be dried is placed. Heated air may be

either blown or sucked through the bed. The air leaving the basket passes

through an air filter and may be recirculated. Particle properties, such as

shape and size distribution, affect fluidization, and a unit must have a

variable air flow adjusted

FIGURE 7.9 Drying curves.

so

that the material is fluidized but is not carried into the filters. For this

reason, the material must have a fairly close size range or else elutriation of

fine particles into the filters will take place.

Fluidized

bed dryers are particularly suitable for granulated materials and are being

increasingly used for tablet granulations provided product changeover is not

too frequent. It may be advantageous to preform other materials, such as a

dewatered filter cake, into granules solely to employ fluidized bed drying. If

fluidizing conditions are ideal, the granulation will not require further

grinding. Tray dryers, on the other hand, produce a caked product that may

require mild comminution. Variation in temperature, which may be quite marked

in tray dryers, is virtually eliminated in fluidized bed dryers by the intense

mixing action. The floor space for a given capacity is smaller compared with a

tray dryer. Machines vary in size, handling up to 250 kg. Drying times,

maximum, minimum, and optimum air velocities, air temperature, and the tendency

to cake and channel are established experimentally as these cannot be predicted

accu-rately at present.

Considerable

erosion and the production of large amounts of fines might be expected from the

intense turbulent movement. Experience shows that the opposite is true. The

particles are to some extent “padded” by the surrounding fluid so that either

the amount of contact between particles is low or the impact energy is small.

Agitated Batch Dryers

Agitated

batch dryers consist of a jacketed cylindrical vessel with agitator blades designed

to scrape the bottom and the walls. The body may be run at atmo-spheric

pressure or under vacuum. Pasty materials, which could not be handled in

tumbling or fluidized bed dryers, may be successfully dried at rates higher

than that can be achieved in an oven.

Freeze-Drying

Freeze-drying

is an extreme form of vacuum drying in which the solid is frozen and drying

takes place by subliming the solid phase (Dushman and Lafferty, 1962; Jennings,

1988; Nail, 1980; Pikal et al., 1984). Low temperatures and pressures are used.

Establishing and maintaining these conditions, together with the low drying

rates obtained, create a most expensive method of drying, which is only used on

a large scale when other methods are inadequate.

There

are two principal fields in which freeze-drying is extensively used. It is used

when high rates of decomposition occur during normal drying. The second field

concerns substances that can be dried at higher temperatures but are thereby

changed in some way. Fruit juices, for example, are reputed to lose subtle

elements of flavor and odor, and proteinaceous materials are partly denatured

by the concentration and higher temperatures associated with con-ventional

drying. Drying of blood plasma and some antibiotics are important large-scale

applications of freeze-drying. On a smaller scale, it is extensively used for

the dehydration of bacteria, vaccines, blood fractions, and tissues.

Freeze-drying

is theoretically a simple technique. Pure ice exhibits an equilibrium vapor

pressure of 4.6 mmHg at 08C

and 0.1 mmHg at – 408C.

The vapor pressure of ice containing dissolved substances will, of course, be

lower. If, however, the pressure above the frozen solution is less than its

equilibrium vapor pressure, the ice will sublime, eventually leaving the solute

as a sponge-like residue equal in apparent volume to the original solid and,

therefore, of low bulk density. The latter is readily dissolved when water is

added, and freeze-drying has been called “lyophilic drying” or “lyophilization”

for this reason. No concentration, in the normal sense of the word, occurs, and

structural changes in, for example, protein solutions, are minimized.

In

practice, many difficulties are encountered. Under conditions of high vacuum,

water vapor must be trapped or eliminated. To maintain drying, heat must be

supplied to the frozen solid to balance the latent heat of sublimation without

melting the frozen solid. Difficulties become acute if, like blood plasma, the

product is dried in the final container under aseptic conditions.

In

the first stage of the process, the material is cooled and frozen. If the

temperature of a dilute solution of a salt is slowly reduced, leveling occurs

in the time-temperature curve just below 08C because of the liberation of the

latent heat of fusion of ice, and pure ice separates. With further cooling, the

solution becomes concentrated until the eutectic mixture is formed. This

freezes to give a plateau in the cooling curve. It is a clear indication of

complete freezing. If the concentration of the liquid eutectic mixture is

small, the material may appear to be completely frozen at higher temperatures.

Under these conditions, some drying from a liquid phase will occur, possibly

with damaging results. This can be detected by measuring the electrical

resistance of the ice that becomes infi-nitely great when the eutectic mixture

freezes. Conversely, thawing gives a marked decrease in resistance, an effect

that can be used to automatically control the state of the drying solid.

Protein solutions do not give clearly defined eutectic points and are usually

frozen to below –258C

before drying. Freezing is carried out quickly to prevent concentration of the

solution and to produce fine ice crystals. Some degree of supercooling may be

induced, followed by a very quick freeze. Freezing may or may not be carried

out in the drying chamber. If drying in final containers is necessary,

small-scale operations may employ immersion in a coolant such as liquid air or

isopentane. Larger-scale installa-tions may cool with a blast of very cold air.

Alternatively, evaporative freezing, in which the liquid is cooled to near its

freezing point and the system is rapidly evacuated, is employed. The

evaporating liquid cools and freezes rapidly. Frothing caused by the evolution

of dissolved gases may complicate this technique. For bulk drying, the liquid

is placed in shallow trays on refrigerated shelves in the drying cabinet.

A

suitable surface area to depth of solid ratio must be provided to facilitate

drying. Thin layers of frozen liquid are used in bulk drying. The surface area

of bottle-dried plasma may be increased by spinning in a vertical axis during

freezing to give a frozen shell about 2 cm thick around the inside periphery of

the bottle. Spinning also prevents frothing during evaporative freezing by

inhibiting the formation of bubbles.

In

plasma processing, freezing, and drying, handling must be carried out

aseptically. This is maintained by a filter at the neck of the bottle that

allows the passage of water vapor but prevents the ingress of bacteria. Similar

precautions are taken during the drying of antibiotics.

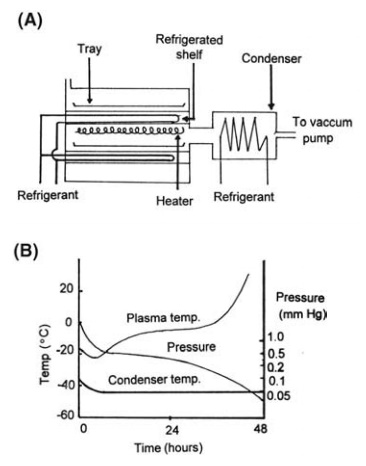

Effective

drying vacuum of 0.05 to 0.2 mmHg may be provided by directly pumping water

vapor and permanent gases, originally present or derived from the drying

material and from leaks, out of the system. Normal practice, how-ever, favors

interposing a refrigerated condenser between the drying surface and the pump.

This arrangement allows a smaller pump, handling mainly permanent gases, to be

used but demands a low condenser temperature, such as –50○C, to remove water

vapor at the low operating pressure. A system for bulk drying in trays is

represented diagrammatically in Figure 7.10A.

During

drying, heat must be supplied to the drying surface. When drying a material,

such as plasma, in a final container, a temperature gradient is established

across the container wall and through the ice to the drying surface by means of

a heater suitably mounted in relation to the container. The power dissipated by

the heater must be carefully controlled so that melting does not occur at the

ice-container junction, the point nearest to the heat source and at the highest

temperature. At any time, the conditions prevailing are such that the rate of

evaporation is approximately constant and temperatures and pressure adjust so

that there is a temperature and pressure gradient from the drying surface to

the condenser. As evaporation proceeds, a drying line recedes into the solid.

With the thinning of the ice layer, the temperature gradient through the ice

will be modified by the decreasing resistance to heat flow. An increase in the

rate of drying due to increase in temperature and vapor pressure of the drying

surface might, therefore, be expected. In practice, this is modified by the

layer of dried plasma that offers considerable resistance to the flow of vapor.

FIGURE 7.10 (A) Equipment for freeze-drying

bulk liquids in trays and (B) variations in tem-perature and pressure during

the freeze-drying cycle for blood plasma.

The

bacterial filter also causes a large, constant pressure drop. Evaporation of

pure ice without the filter and plasma layer would be 300 times faster. When

the plasma is nearly dry, its temperature is allowed to rise to about 308C to facilitate final drying. The

total drying time is about 48 hours. The temperatures and pressure in the

system during this period are shown, as a function of time, in Figure 7.10B.

If

the product is not being dried in its final container, radiant heat may be used

to provide the latent heat of sublimation. If the dried solid could be removed

continuously, high drying rates are possible. Not only is heat provided

directly to the drying surface, but there is also little danger of melting the

ice at the container wall.

Related Topics