Continuous Dryers

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Drying

Continuous Dryers : Spray Dryers, Drum Dryers

CONTINUOUS DRYERS

Although

many types of continuous dryers are available, the scale of the operation for

which they are designed is rarely appropriate for pharmaceutical manufacture.

As with most continuous plant items, the cost is dis-proportionately high for

small units. Spray and drum dryers provide an exception to this comment because

residence times in the dryers are short and thermal degradation is minimized.

Under some conditions, freeze-drying may be the only practicable alternative.

Spray Dryers

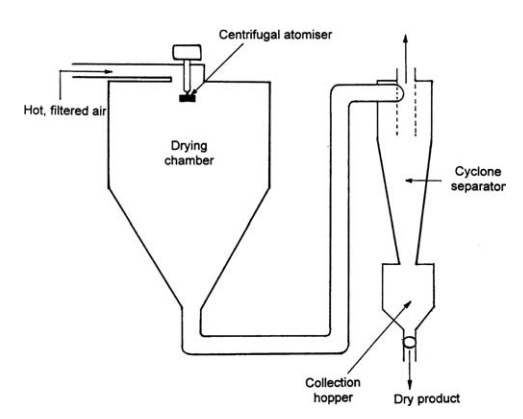

As

the name implies, the solution or suspension to be dried is sprayed into a hot

airstream and circulated through a chamber. The dried product may be carried

out to cyclone or bag separators or may fall to the bottom of the drying

chamber and be expelled through a valve. The chambers are normally cylindrical

with a conical bottom, although proportions vary widely. A typical spray dryer

is illustrated in Figure 7.11 (Masters, 1991; Sacchetti and Van Oort, 2006).

FIGURE 7.11 Spray

dryer.

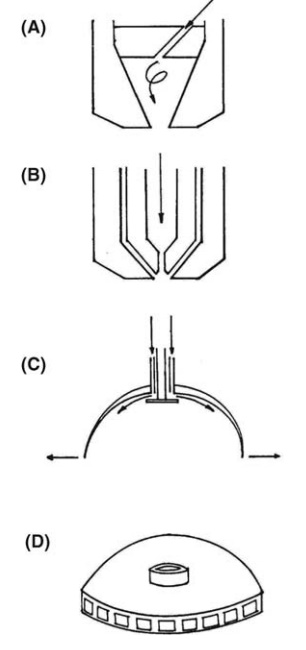

FIGURE 7.12 Schematic diagrams of atomizers

for spray drying.

The

process can be divided into four sections: atomization of the fluid, mixing of

the droplets, drying, and, finally, removal and collection of the dry

particles.

Atomization

may be achieved by means of single fluid or two fluid nozzles or by spinning

disk atomizers. The single fluid nozzle, illustrated in Figure 7.12, operates

by forcing the solution under pressure through a fine hole into the airstream.

An intense swirl is conferred on the liquid before it emerges from the orifice.

This causes the jet to break up. In the two fluid nozzles, shown in Figure

7.12, a jet of air simultaneously emerges from an annular aperture con-centric

with the liquid orifice. Both types are subject to clogging and severe erosion,

so neither is well suited to spraying suspensions. The spinning disks are most

versatile and consist, in their simplest form, of a mushroom-shaped disk

spinning at 5000 to 30,000 rpm. Other designs include the slotted disk (Fig.

7.12), which will spray thick suspensions and, if special feeding arrangements

are used, pastes. The main factors that determine the size of the droplets are

the viscosity and surface tension of the liquid, the fluid pressure in the use

of nozzles, or, for spinning disks, their size and speed of rotation. A

reasonably uniform and controllable size within the range 10 to 500 μm is desirable.

In

vertical spray dryers, the flow of the drying gas may be concurrent or

countercurrent with respect to the movement of droplets. The movement of the

gas is, however, complex and highly turbulent. Good mixing of droplets and gas

occurs, and the heat and mass transfer rates are high. In conjunction with the

large interfacial area conferred by atomization, these factors give very high

evaporation rates. The residence time of a droplet in the dryer is only a few

seconds (5–30 seconds). Since the material is at wet bulb temperature for much

of this time, high gas temperatures of 150○C to 200○C may be used even

with thermolabile materials. Although the temperature of the material rises

above the wet bulb temperature at the end of the process, the drying gases will

be cooler and the material will be almost dry, a condition in which many

materials are thermally less sensitive. For these reasons, it is possible to

dry complex vege-table extracts, such as coffee or digitalis, milk products,

spore suspensions, and other labile materials without significant loss of

potency or flavor.

Drying

is considered to take place by simple evaporation rather than by boiling, and

it has been observed that a droplet reaches a terminal velocity within about 30

cm of the atomizer. Beyond this, there is no relative velocity between the

droplet and the drying gas unless the former is very large. The droplets may

dry to form a solid, spherical particle. If, however, the emerging solids form

a skin, internal pressure may inflate the particle, and the final dry form will

be hollow spheres that may or may not have a blow hole. These xenospheres may

also fragment so that the final product occurs as agglomerates of finely

divided solids. It has been found experimentally that the product’s bulk

density, which is lowest for xenospheres and highest for fragmented solids,

increases as the inlet air temperature is lowered and as the drop size

increases. A higher feed concentration also increases the bulk density because

drops of the same size give spheres with thicker walls.

These

attractive physical characteristics lend further advantage to spray drying. The

product often has excellent flow and packing properties that greatly facilitate

handling and transport. As an example, spray-dried lactose is a widely used

tablet excipient, which will flow, pack, and compact without prior

gran-ulation. Similarly, a slurry of fillers and other excipients could be

granulated by spraying and drying. After adding an active principle, the mix

could be com-pressed without further processing.

The

capital and running costs of spray dryers are high, but if the scale is

sufficiently large, they may provide the cheapest method. When thermolabile

materials are dried on a small scale, costs will be 10 to 20 times greater than

that for oven drying. Air used to dry fine chemicals or food products is heated

indirectly, thus reducing thermal efficiency and increasing costs. In some

other installations, hot gases from combustion may be used directly.

Drum Dryers

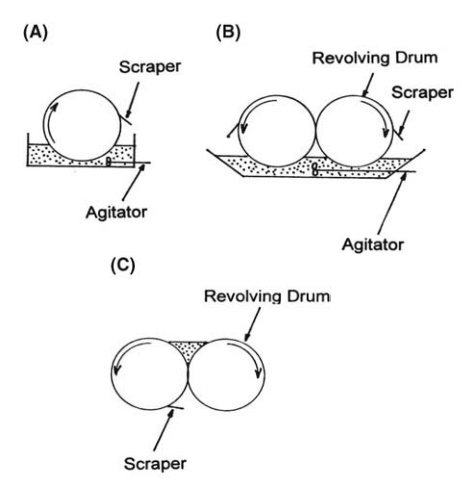

The

drum dryer consists of one or two slowly rotating, steam-heated cylinders.

These are coated with solution or slurry by means of a dip feed, illustrated in

Figure 7.13, in which the lower portion of the drum is immersed in an agitated

trough of feed material or, in the case of some double drum dryers, by feeding

the liquor into the gap between the cylinders, as shown in Figure 7.13. Spray

and splash feeds are also used. When dip feeding is employed, the hot drum must

not boil the liquid in the trough. Drying takes place by simple evaporation

rather

FIGURE 7.13 Drum dryers.

Drying

capacity is influenced by the speed of the drum and the temper-ature of the

feed. The latter may be preheated. With the double drum dryer, the gap between

the cylinders determines the thickness of the film.

Drum

dryers, like spray dryers, are relatively expensive in small sizes, and their

use in the pharmaceutical industry is largely confined to drying thermo-labile

materials where the short contact time is advantageous. Drums are nor-mally

fabricated from stainless or chrome-plated steel to reduce contamination. The

heat treatment to which the solid is subjected is greater than that in spray

drying, and the physical form of the product is often less attractive. During

drying, the liquid approaches its boiling point and the dry solids approach the

temperature of the drum surface.

Related Topics