Inhalation Products

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Solid Dosage Forms

Solid particles are employed in two types of inhalation product: the pressurized metered-dose inhaler (pMDI) and the dry powder inhaler (DPI).

INHALATION PRODUCTS

Solid

particles are employed in two types of inhalation product: the pressurized

metered-dose inhaler (pMDI) and the dry powder inhaler (DPI). In both cases,

the method of choice for manufacturing particles in an appropriate size range

to deposit in the lungs (<5

μm) is attrition

milling by air jet mill.

The

pMDI product is prepared as a nonaqueous suspension in which surfactant is used

to disperse the drug particles in high–vapor pressure pro-pellants. Once the

particles are prepared, the product formulation depends only on the particle

dispersion in suspension, their ease of redispersion, and their physical

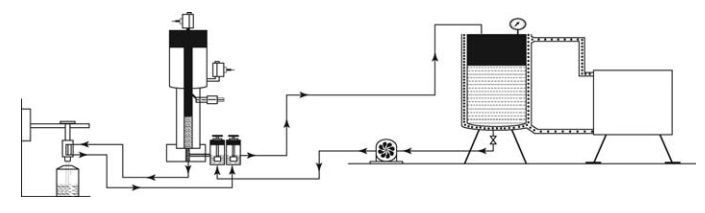

stability upon aerosolization. Figure 14.9 shows a typical filling line for

pMDI product.

DPI

formulations usually involve a combination of the micronized drug with a

carrier, notably lactose. The carrier particles are usually larger than the

drug particles and outside the range required for lung deposition (>30 mm). The purpose of these large

particles is to help disperse the respirable drug particles carrying them into

the inspiratory airflow where they are stripped from the surface as a function

of the large shear forces. These formulations are prepared in capsules,

blisters, or reservoir devices. The filling technology has been developed to

accurately meter small doses into the unit-dose packaging.

Other

methods of particle preparation have been evaluated, including spray drying and

supercritical fluid manufacture. The capacity to manufacture particles with

known and optimized particle size, shape, and surface charac-teristics is

intriguing, and it seems likely that these methods will become more significant

in the future and may even surpass micronization for aerosol delivery of drugs.

FIGURE 14.9 Metered-dose inhaler filling line.