Tablets

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Solid Dosage Forms

Additional processes are required for tablet production beyond those described previously.

TABLETS

Additional

processes are required for tablet production beyond those described previously.

Because these processes are not ubiquitous in pharmaceutical manufacturing,

they are dealt with only briefly here. Many of them are required for all solid

dosage forms. Each process must be conducted while balancing the effects of the

respective excesses.

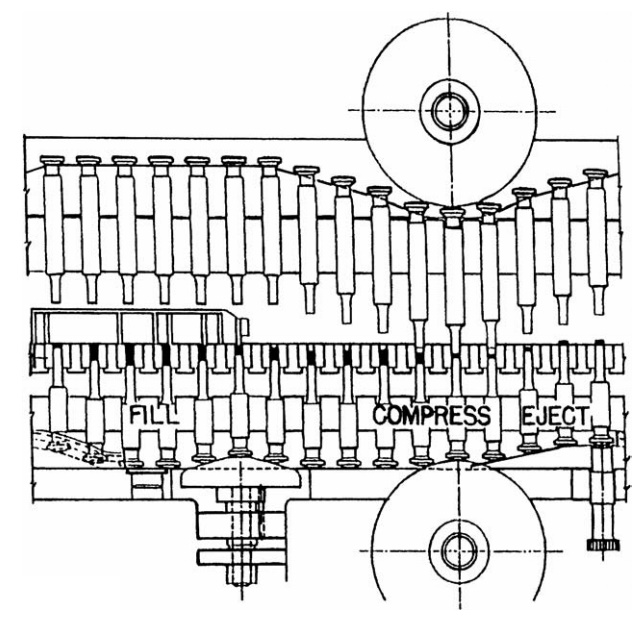

Compressed

solids, tablets, or caplets are prepared by placing the blend of component

additives in a cylinder or die, above a movable piston or punch. An upper punch

is brought into the top of the piston, and pressure applied to the distal ends

of the punches forces the powder into a compact (Fig. 14.7). Product quality

depends on the cohesive forces acting on the powder under compres-sion. These

cohesive forces are influenced by the selection of additives in the dosage

formulation. One method of evaluating tablet manufacture considers the effect

of applied pressure on porosity of the compressed powder (Carstensen, 1993).

Data may be plotted as the negative natural logarithm of porosity against

applied pressure in the form of a Heckel plot (Heckel, 1961). The slope is

pro-portional to the yield value (φ, elastic limit) l/3φ.

The

tooling of a tablet press varies according to the tablet design. Con-sideration

must be given to the distribution of forces across the faces of the tablet

punches as they are brought together to compress the tablet in the die. As more

unusually shaped tablets are produced and more elaborate embossing tools are

required, the forces are not distributed evenly across the punches, and care

must be taken if they are to have a reasonable, useful life span.

Mathematically, finite element analysis can be used to characterize these

forces and to calculate the requirement for preserving the tools· for extended

periods.

FIGURE 14.7 Tablet manufacture depicting the

three steps of filling, compression, and ejection.

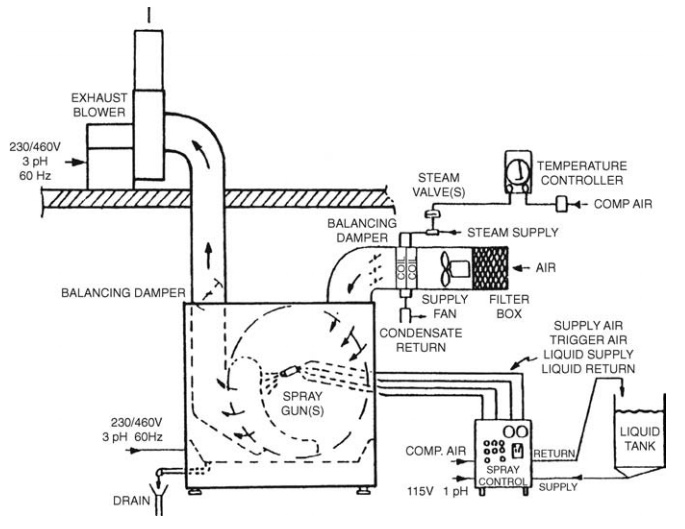

Coating is achieved

by placing a batch of tablets in a coating pan and spraying or coating from

solution with the required polymer. The Accela-Cota (Fig. 14.8) is one of the

more common coating systems.

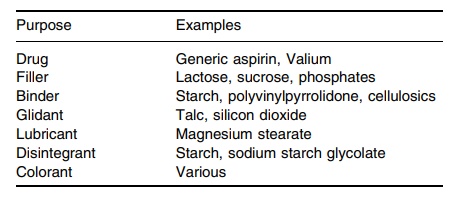

Tablets have been

prepared with different characteristics and for different purposes. The most

common tablets are uncoated, coated, chewable, or effer-vescent. Some

specialized dosage forms have been developed for sublingual and buccal

delivery. A typical uncoated conventional tablet might have the com-position

shown in Table 14.1. Examples of such systems include generic aspirin and

Valium. These tablets are designed for rapid dissolution.

Tablets may be

coated for a variety of reasons, including better appear-ance, taste masking,

ease of swallowing, protection from light, protection from gastrointestinal

irritation, facilitating tablet printing, and control release. The formulation

of a coated tablet is similar to that of an uncoated tablet. Usually, it is

coated from a solution of polymer, for example, methylcellulose, enteric

polymer. Bayer aspirin or erythromycin products are examples of coated tablets.

Chewable

tablets are usually flavored and contain additives that contrib-ute to a smooth

texture, including glycerin and sugars such as mannitol and sorbitol. An

example is Tylenol chewable tablets.

FIGURE 14.8 Accela-Cota. Source: Courtesy of Thomas Engineering, Hoffmann Estates,

Illi-nois, U.S.

TABLE 14.1 Tablet Composition

Effervescent tablets

are formulated so that an acid-base reaction occurs when they are combined with

water. This is achieved by using weak acids (e.g., citric, malic, tartaric, or

fumeric acids) or bases (e.g., sodium or potassium carbonates) in the product.

The best known of these products is Alka-Seltzer.

Sublingual

tablets are designed to disintegrate and dissolve instantly. Hence, they must

have structural integrity sufficient for storage, transport, and administration

but capable of dissolution on the oral mucosa under the tongue. Nitroglycerin

tablets designed for treating angina are prepared in a composi-tionally simple

formulation of lactose massed with 60% ethanol. This route of administration is

intended to avoid first-pass liver metabolism. Testosterone tablets have been

prepared for buccal delivery by slow dissolution. The tablet does not contain a

disintegrant and is intended to have an extended residence time in the buccal

cavity at the rear of the mouth. Since release is not immediate, drug dosage

may be significantly reduced by this route.