Thixotropy

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Rheology

Thixotropy is the property of some non-Newtonian fluids to show a time-dependent change in viscosity.

Thixotropy

Thixotropy

is the property of some non-Newtonian fluids to show a time-dependent change in

viscosity. For dilatant (shear-thickening) thixotropic fluids, the longer the

fluid undergoes shear, the more its viscosity. For pseudoplastic

(shear-thinning) thixotropic fluids, the longer the fluid undergoes shear, the

lower its viscosity.

Many

gels and colloids are pseudoplastic thixotropic materials, exhibiting a stable

form at rest but becoming fluid when agitated with a reversible gel–sol

transformation phenomenon. When sheared by mixing, such as simple shaking, the

matrix relaxes and forms a solution with the charac-teristics of a liquid

dosage form for ease of use. Although pseudoplastic fluids show thinning with

only increasing rate of shear, thixotropic fluids show increasing flow and

thinning as the duration of mixing increases, even at the same shearing forces.

On setting, the higher-viscosity plastic state resumes as a network gel forms

and provides a rigid matrix that stabilizes suspensions and gels.

The

molecular basis of thixotropic behavior of fluids lies in changes in

intermolecular interactions of solute on persistence of shear. Thus,

pseudo-plastic thixotropic systems show thinning behavior not only with

increasing shear but also with increasing duration of shear, owing to changes

in the alignment of solute molecules that reduce their intermolecular

interactions. Conversely, dilatant thixotropic systems show thickening behavior

not only with increasing shear but also with increasing duration of shear,

owing to swelling and/or intermolecular entanglement or interparticle

interactions, which cause increased interparticle bonding or intermolecular

attractive interactions with time.

The

term thixotropic fluid is sometimes used to refer to pseudoplastic

(shear-thinning) thixotropic behavior. Conversely, the term negative

thix-otropy or antithixotropy is sometimes used to refer to a dilatant

(shear-thickening) thixotropic behavior, that is, a time-dependent increase

rather than a decrease in apparent viscosity on application of a shearing

stress.

The

main advantage of pseudoplastic thixotropic preparations is that the particles

remain in suspension during storage, but when required for use, the pastes are

readily made fluid by tapping or shaking. This is true for both pseudoplastic

and thixotropic fluids. For thixotropic fluids, the duration of shearing or

shaking, even at the same shear stress, also impacts shear thin-ning to the

fluid. For example, concentrated parenteral suspensions con-taining from 40% to

70% w/v of procaine penicillin G in water show high inherent pseudoplastic

thixotropic behavior.

Hysteresis loop

Hysteresis

loop represents different path of response (shear rate) to the experimental

parameter (shear stress) when the experimental parameter is increased or

decreased. Thixotropic systems show an up–down curve, called hysteresis loop,

such that for a given shear stress, the flow response is a function of the

history of the sample—increasing the shear stress (up curve) leads to different

flow behavior than if the shear stress were decreas-ing (down curve). Typical

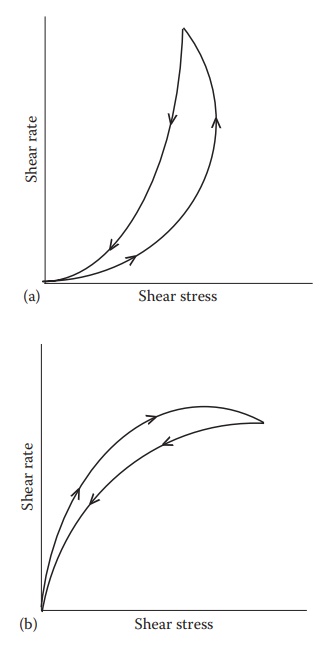

rheograms for pseudoplastic and dilatant systems exhibiting this behavior are

shown in Figure 12.2.

Figure 12.2 Thixotropy in pseudoplastic and

dilatant flow systems: (a) thixotropy in pseudoplastic material and (b)

thixotropy in dilatant material.

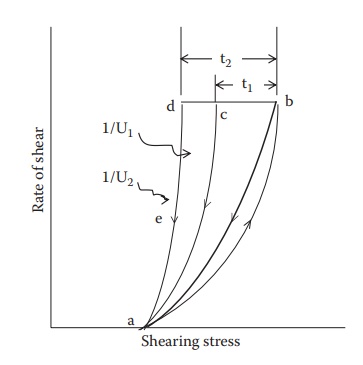

Rheograms

of pseudoplastic thixotropic materials are highly dependent on the rate at

which shear is increased or decreased and the length of time for which a sample

is subjected to any one rate of shear or shear stress. As shown in Figure 12.3 for a pseudoplastic thixotropic system

shown in Figure 12.2a, the shear rate (or flow)

increases from point “a” to point “b” with an increase in shear stress and

decreases from “b” to “e” with a decrease in the shear stress. This forms the

hysteresis loop “abe.” However, if the sample was taken to point “b” and the

shear rate was held constant for a certain period of time (say, t1 seconds), the rate of

shear (and hence the consistency and

Figure 12.3 Relationship between shearing stress and rate of shear for a plastic system possessing thixotropy.

Consequently, to maintain the same

desired rate of shear (as in point “b”), the amount of shear stress required is

progressively lower as time passes (t2

> t1)—represented by

the horizontal line from “b” to “c” for t1 and “b” to “d” for t2

in Figure 12.3. This decrease in the required

shear stress to maintain the same rate of shear is attributed to reduction in

the degree or amount of structure in the sample.

Decreasing

the rate of shear to zero after having reached the state “b,” “c,” or “d”

(depending on the time for which shear stress is applied at con-stant shear

rate) would create hysteresis loops aba, aca, or ada, respectively. Therefore,

in contrast to pseudoplastic or dilatant materials, the rheogram of a

thixotropic material is not unique but depends on the rheologic history of the

sample and the approach used to obtain the rheogram. For example, keeping the

constant shear stress at point “b” for times t1 and t 2

would result in very different rheograms than the rheogram shown in Figure 12.3, where the shear rate was kept constant

at point “b.” Student exercise: draw the rheograms for the case where shear

stress is kept constant for times t1

and t2 at point “b” and

compare them with that in Figure 12.3. This

property of thixotropic systems is important to bear in mind when attempting to

obtain a quantitative measure of viscosity and flow of thixotropic systems.

Related Topics