Stability

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Dosage forms - Emulsions

Emulsions must demonstrate physical, chemical, and microbial stability throughout their shelf life under recommended packaging and storage conditions.

Stability

Emulsions

must demonstrate physical, chemical, and microbial stability throughout their

shelf life under recommended packaging and storage conditions.

Physical instability

Physical

stability of an emulsion is characterized by the maintenance of elegance with

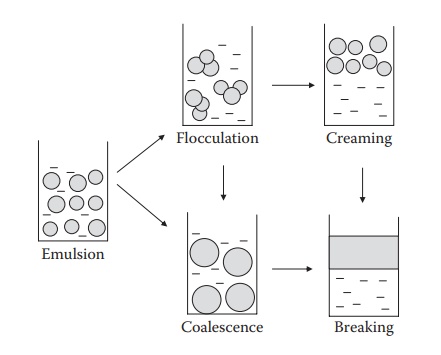

respect to appearance, odor, color, taste, opacity, and viscos-ity. Four major

phenomena are associated with the physical instability of emulsions: (1)

flocculation, (2) creaming, (3) coalescence, and (4) breaking. These phenomena

are schematically illustrated in Figure 17.2.

Flocculation is discussed under the chapter on suspensions.

Figure 17.2 Schematic illustrations of different types of instability of emulsions.

Creaming and sedimentation

Creaming is the upward

movement of dispersed oil droplets in an o/w

emulsion, whereas sedimentation,

the reverse process, is the downward movement of dispersed-phase droplets.

Creaming involves visually evident separation of two layers that differ

primarily in the number density of the dispersed phase, and, thus, show optical

differences. These processes take place due to the density differences in the

two phases and can be reversed by shaking. Creaming is undesirable because a

creamed emulsion increases the likelihood of coalescence due to the closer

proximity of the globules in the cream and because of the nonuniformity of the

creamed emulsion. The propensity and rate of creaming is influenced by factors

similar to those involved in the sedimentation of suspensions and are indicated

by the Stoke’s Law, as discussed in a preceding Section

17.4.3.

Aggregation, coalescence, creaming, and breaking

Aggregation

involves close packaging/contact of the dispersed-phase drop-lets, but the

droplets do not fuse. Aggregation is, to some extent, reversible. Coalescence

is the process by which emulsified globules merge with each other to form

larger globules. Coalescence is an irreversible process because the film that

surrounds the individual globules is destroyed. It leads to pro-gressive

increase in the size of the dispersed phase, ultimately leading to breaking of

the emulsion. Breaking of an emulsion refers to complete sepa-ration of the two

liquid phases. Creaming is a reversible process, whereas breaking is

irreversible. When breaking occurs, simple mixing fails to resus-pend the

globules in a stable emulsified form, since the film surrounding the particles

has been destroyed and the oil tends to coalesce. The proportion of the volume

of emulsion occupied by creamed layer is an indicative of the stability of an

emulsion. Greater the proportion of the creamed layer, more stable the

emulsion. Flocculation, which leads to weak interactions between

dispersed-phase droplets, can stabilize an emulsion by increasing the dura-tion

of time it takes for creaming and the proportion of the creamed phase.

Formation

of a thick interfacial film is essential to minimize coalescence. In addition,

increasing the mechanical strength of the interfacial barrier, such as by

closer packing of the interfacial surfactant monolayer, reduces the propensity

toward coalescence. Increasing the viscosity of the continu-ous phase helps to

stabilize the dispersed phase and minimizes coalescence.

Particle

size does not correlate well with increased/decreased breaking, nor does

viscosity. Phase volume is an important consideration in the stability of an

emulsion. For example, at greater than ~74% of oil in an o/w emulsion, the oil

globules often coalesce and breaking occurs. Thus, a critical concentra-tion is

defined in terms of the concentration of the internal phase above which the

emulsifying agent cannot produce a stable emulsion of the desired type.

Generally, a phase-volume ratio of 50:50 results in the most stable emulsion.

Phase inversion

An

emulsion is said to invert when it changes from an o/w to a w/o emul-sion, or

vice versa. Phase inversion can occur by the addition of an elec-trolyte or by

changing the phase volume ratio. Addition of monovalent cations promotes the

formation of o/w emulsions, whereas the addition of divalent cations increases

the propensity toward the formation of w/o emulsions. For example, an o/w

emulsion stabilized with sodium stearate can be inverted to a w/o emulsion by

adding calcium chloride to form cal-cium stearate.

Chemical instability

The

API must be chemically stable in the dosage form throughout the shelf life of

the product under recommended packaging and storage conditions in terms of both

potency and impurities. The drug product must meet pre-determined requirements

of minimum potency of the API and maximum levels of known and unknown

impurities. Factors governing the reaction kinetics of the API, such as the

reactivity of functional groups and the kinetics of reactions are no different

for emulsion dosage forms than other solution-based dosage forms. Nevertheless,

separation of the reacting spe-cies in the oily and aqueous phases can minimize

reactivity and improve stability of a drug in an emulsion.

Microbial growth

Microbial

load of a dosage form must be controlled within the compendial and the

regulatory levels. In addition to the health risks of microbial growth,

microorganisms in an emulsion can cause physical separation of the phases.

Preservatives must be added in adequate concentrations in the formulations to

resist microbial growth. The preservative should be concentrated in the

aqueous phase because bacterial growth will normally occur there. The oil and

water partition coefficient of the preservatives should be considered to

calculate the concentration of the surfactant in the aqueous phase, which needs

to be above the antimicrobial concentration. The para-bens (methylparaben,

propylparaben, and butylparaben) are the commonly used preservatives in

emulsions.