Review questions answers

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Dosage forms - Emulsions

Pharmaceutical Drugs and Dosage: Dosage forms - Emulsions - Review questions answers

Review questions

17.1 Coalescence

can be reduced by

A. Decreasing the

difference between the density of the dispersed phase and the density of the

medium

B. Adding an agent that

reduces the viscosity of the medium

C. Increasing the

droplet size of the dispersed phase

D. All of the above

17.2 When

compounding an emulsion that contains a flavoring agent, the flavoring agent should

be in the

A. Continuous phase

B. Discontinuous phase

C. Aqueous phase

D. Oil phase

E. Emulsifier

17.3 Define

and differentiate between the following:

A. Creaming and

breaking

B. Creaming and

sedimentation

C. Coalescence and

aggregation

D. Phase inversion and

self-emulsification

E. Multiple emulsions

and microemulsions

F. SEDDS and SMEDDS

17.4 Explain

how sedimentation and creaming in emulsions can be minimized. 17.5 Why is a surfactant

needed to make stable emulsions? Explain which properties of a surfactant are important in formulating emulsions.

Enlist two factors that determine whether an emulsion is o/w or w/o.

17.6 List the

three mechanisms of emulsification.

17.7 What are

emulsifying agents? List the three types of emulsifying agents and differences in their

mechanism of stabilization of an emulsion, for example, in terms of the type of

film formed around the dispersed phase and the zeta potential on the dispersed

phase.

17.8 Which

surfactants will you select for o/w and w/o emulsification.

17.9 Identify

the type of self-emulsifying system most appropriate for the following statements

(SEDDS or SMEDDS):

A. Has lower

dispersed-phase globule size after emulsification

B. Has higher content

of oil

C. Has higher content

of cosolvent

D. Is transparent in

appearance after emulsification

E. Is likely to have

higher oral bioavailability

17.10 Which of

the following surfactants is suitable for the formulation of a o/w emulsion?

A. Surfactant with an

HLB value of 1–3

B. Surfactant with an

HLB value of 3–6

C. Surfactant with an

HLB value of 6–9

D. Surfactant with an

HLB value of 9–12

E. Surfactant with an

HLB value of 12–15

F. Surfactant with an

HLB value of 15–18

17.11 Which of

the following surfactants is suitable for the formulation of a w/o emulsion?

A. Surfactant with an

HLB value of 1–3

B. Surfactant with an

HLB value of 3–6

C. Surfactant with an

HLB value of 6–9

D. Surfactant with an

HLB value of 9–12

E. Surfactant with an

HLB value of 12–15

F. Surfactant with an

HLB value of 15–18

Answers:

17.1 A.

17.2 A.

17.3 A. Creaming

and breaking: Creaming is the upward movement of

dispersed droplets relative to the continuous phase and it is a reversible

process. In contrast, breaking is irreversible. When breaking occurs, simple

mixing fails to resuspend the globules in a stable emulsified form, since the

film surrounding the particles has been destroyed and the oil tends to

coalesce.

B. Creaming and

sedimentation: Creaming is the upward movement of dispersed droplets relative to the

continuous phase, whereas sedimentation is

the downward movement of particles.

C. Coalescence and

aggregation: Coalescence is the process by which the emulsified particles merge with

each other to form large par-ticles. Coalescence is an irreversible process

because the film that surrounds the individual globules is destroyed. In

aggregation, dispersed droplets come together but do not fuse. Aggregation is

to some extent reversible.

D. Phase inversion: An emulsion is

said to invert when it changes from

an o/w to a w/o emulsion or vice versa. Phase inversion can occur by the

addition of an electrolyte or by changing the phase:volume ratio. Monovalent

cations tend to form o/w emul-sions, whereas divalent cations tend to form w/o

emulsions. An o/w emulsion stabilized with sodium stearate can be inverted to a

w/o emulsion by adding calcium chloride to form calcium stearate.

17.4 Creaming is the upward movement of dispersed droplets relative to the continuous phase,

whereas sedimentation is the downward movement of particles. Factors that

influence the rate of creaming are similar to those involved in the rate of

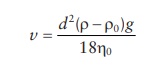

sedimentation. According to Stokes’ law,

where:

v is the velocity of

creaming

d is the globule

diameter

ρ

and ρ0 are the densities

of dispersed phase and dispersion medium, respectively

η

is the viscosity of the dispersion medium (poise)

g is the acceleration

of gravity (981 cm/s2)

According

to this equation, we can minimize sedimentation and creaming phenomena by

·

A reduction in the globule size

·

A decrease in the density difference between the two phases

·

An increase in the viscosity of the continuous phase

17.5 A.

Increased free energy at the interface occurs because the increase in surface area of

dispersed phase is responsible for the instability of the emulsion. The

surfactants deposit on the interface between the two liquid phases and reduce

the interfacial tension and free energy at the interface.

B. HLB value of surfactant and relative concentration of the

two phases.

17.6 Emulsifying

agents form a film around the dispersed globules to pre-vent coalescence and

thus avoid the separation of two immiscible liq-uids used for emulsion

formation. Emulsifying agents aid in forming emulsions through three different

approaches: (1) reduction of inter-facial tension, (2) formation of a rigid

interfacial film, and (3) forma-tion of an electrical double layer. The film

can act as a mechanical barrier to the coalescence of the globules. An

electrical double layer minimizes coalescence by producing electrical forces

that repulse approaching droplets. Emulsifying agents can be divided into three

groups: (1) surfactants, (2) hydrophilic colloids, and (3) finely divided solid

particles.

·

Surfactants are adsorbed at

oil–water interfaces to form

mono-molecular films and reduce interfacial tensions.

·

Hydrophilic colloids

are

used as emulsifying agents. These include

proteins (gelatin and casein) and polysaccharides (acacia, cellulose

derivatives, and alginates). These materials adsorb at the oil–water interface

and form multilayer films around the

dispersed droplets of oil in an o/w emulsion. Hydrated lyophilic colloids

differ from sur-factants as they do not cause an appreciable lowering in

interfacial tension.

·

Finely divided solid

particles are

adsorbed at the interface between two

immiscible liquid phases and form a film

of par-ticles around the dispersed globules. Finely divided solid

par-ticles are concentrated at the interface, where they produce a particulate

film around the dispersed droplets so as to prevent coalescence.

17.7 In

general, o/w emulsions are formed when the HLB of the surfactants is within the range of

about 9–12, and w/o emulsions are formed when the range is about 3–6.

17.8 A

surfactant with a high HLB value (~9–12) is used as an emulsifier to form o/w emulsions;

and a surfactant of low HLB value (~3–6) to form w/o emulsions.

17.9 A. SEDDS

B. SEDDS

C. SMEDDS

D. SMEDDS

E. SMEDDS

17.10 D.

17.11 B.