Antibiotics Assays - Examples of Pharmaceutical Microbial Assays

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Microbiological (Microbial) Assays: Antibiotics-Vitamins- Amino Acids

The microbial assays of ‘antibiotics’ are usually carried out by two standard methods as per Indian Pharmacopoea.

EXAMPLES

OF PHARMACEUTICAL MICROBIAL ASSAYS

The microbial assays have been effectively

extended to a plethora of pharmaceutical

preparations i.e., the secondary

pharmaceutical products. However, this particular section will deal with only the following three types of such products, namely :

(1) Antibiotics,

(2) Vitamins,

and

(3) Amino

Acids.

Antibiotics Assays

The

microbial assays of ‘antibiotics’

are usually carried out by two

standard methods as per Indian Pharmacopoea (1996), namely :

Method A i.e., the ‘Cylinder-Plate Method’ as discussed in Section 10.1.3.1 and

Section 10.3.1.

Method B i.e., the ‘Turbidimetric Method’ as described in Section 10.1.3.2.

A

comprehensive account of the ‘Antibiotic

Assays’ shall now be dealt with under the following sub-heads :

Standard Preparation and Units of Activity

Standard preparation may be

defined as— ‘the authentic sample of the

appropriate antibi-otic for which the potency has been precisely determined

with reference to the appropriate inter-national standard’

However,

the potency of the standard preparation

may be duly expressed either in Interna-tional

Units (IU) or in μg.mg–1 with

respect to the ‘pure antibiotic’.

Important Points

(1) Standard Preparation for India

are adequately maintained at the Central Drugs Labora-tory, Kolkata. A

unit referred to in the ‘official assays’ and ‘tests’ refers to the

specific activity con-tained in such an amount of the respective standard preparation as is duly

indicated by the Ministry of Health and Family Welfare, Government of India

from time to time.

(2) Standard Preparation may be

suitably replaced by a ‘working

standard’ prepared by any laboratory

that must be compared at definite intervals under varying conditions with the ‘standard’.

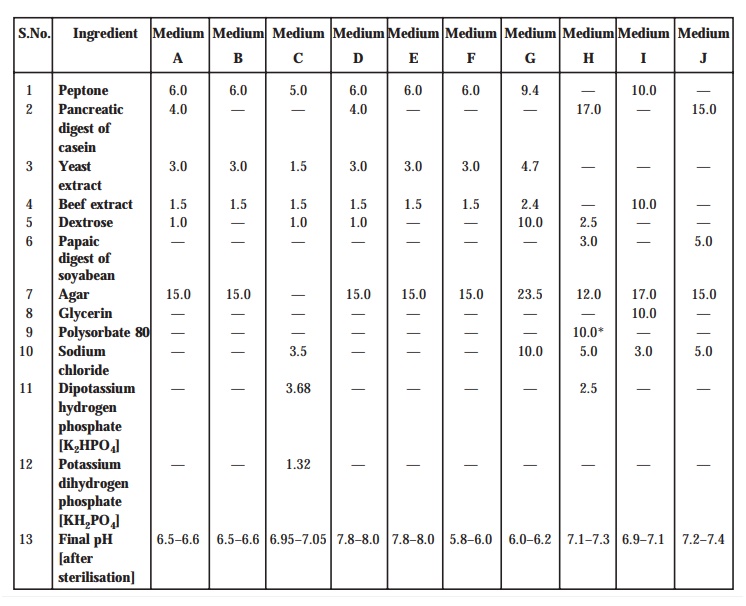

[A] Media. The media necessarily required for the preparation of ‘test organism inocula’ are duly made from the various ingredients

as listed specifically in Table : 10.1. However, one may make minor

modifications of the individual ingredients as and when required or ‘reconstituted dehydrated media’ may be employed provided the resulting media have either almost

equal or definitely better growth-promoting

characteristic features, and ultimately give a similar standard curve-response.

Method : Dissolve the various prescribed

ingredients in sufficient distilled water (DW) to pro-duce 1L, and add

sufficient 1M sodium hydroxide or 1M hydrochloric acid, as required so

that after sterilization the pH must be as stated in Table : 10.1.

TABLE 10.1. Composition of Media : Quantities in

g.L–1

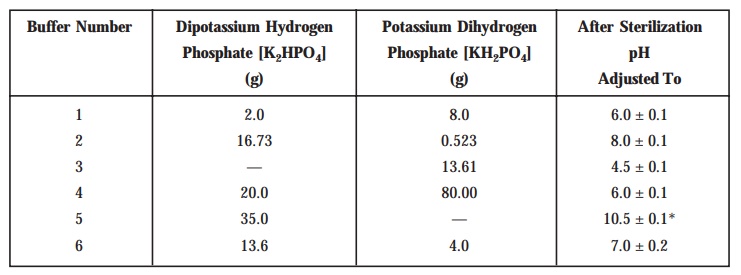

[B] Buffer Solutions : Prepare

the buffer solutions by dissolving

the quantities (see Table 10.2) of K2HPO4

and KH2PO4 in sufficient distilled water to produce 1L

after adjusting the pH with 8 M . H3PO4 or 10 M.KOH. The buffer solutions are

duly sterilized after prepares and the final pH specified in each case must be the one that is

obtained after sterilization.

Table 10.2 : Buffer Solutions

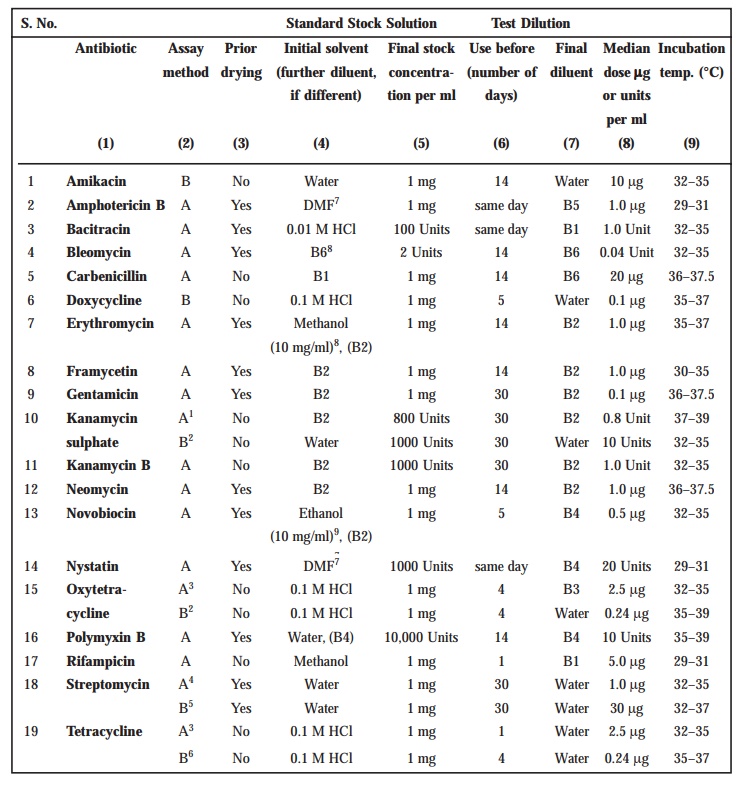

Preparation of Standard Solution

In order

to prepare a ‘Stock Solution’,

dissolve a quantity of the Standard

Preparation of a given antibiotic,

weighed accurately and precisely, and dried previously as duly indicated in

Table 10.3 in the solvent specified in the said Table ; and subsequently dilute

to the required concentration as indicated specifically. It is advisable to

store the ‘Stock Solution’ duly in a

refrigerator (+ 1–5°C), and use within the stipulated period indicated.

On the

particular day intended for carrying out the assay, prepare from the ‘Stock Solution’ at least five or even more test dilutions

whereby the successive solutions increase stepwise in concentra-tion,

invariably in the ratio 1 : 1.25 for

method A or smaller for method B. Use the final diluent

specified and a sequence in a such a manner that the middle or median should

have the concentration as specified duly in Table 10.3.

Preparation of Sample Solution

Based on

the available information for the ‘drug

substance’ under investigation (i.e.,

the ‘un-known’) assign to it an

assumed potency per unit weight or volume, and on this assumption prepare on the day of the assay a ‘Stock Solution’ and test dilution(s) as duly specified for

each individual antibi-otic in Table 10.3, taking particular care to use the same final diluent as employed for the Standard Preparation. The assay with 5 levels of the Standard necessarily requires only one level of the ‘un-known’ at a concentration assumed

very much equal to the ‘median level’ of

the ‘Standard’.

TABLE 10.3 : Stock Solutions and Test Dilutions of

Standard Preparations

For Amphotericin B, further dilute the stock

solution with dimethylformamide to give concentrations of 12.8, 16, 20, 25 and

31.2 μg per ml

prior to making the test solutions. The test dilution of the sample prepared

from the solution of the substance being examined should contain the same

amount of dimethylformamide as the test dilutions of the Standard Preparation.

For Bacitracin, each of the standard test dilutions

should contain the same amount of hydrochloric acid as the test dilution of the

sample.

For Nystatin, further dilute the stock solution

with dimenthylformamide to give concentrations of 64.0, 80.0, 100.0, 125.0 and

156.0 μg per ml

prior to making the test dilutions. Prepare the standard response line

solutions simultaneously with dilutions of the sample being examined. The test

dilution of the sample pre-pared from the solution of the substance being

examined should contain the same amount of dimethylformamide as the test

dilutions of the Standard Preparation. Protect the soultions from light.

When making the stock solution of Polymyxin B, add

2 ml of water for each 5 mg of the

weighed Standard Preparation material.

Where indicated, dry about 100 mg of the Standard

Preparation before use in an oven at a pressure not exceeding 0.7 kPa at 60°

for 3 hours, except in the fine of Bleomycin (dry at 25° for 4 hours),

Novobiocin (dry at 100° for 4 hours), Gentamicin (dry at 110° for 3 hours) and

Nystatin (dry at 40° for 2 hours).

Where two-level factorial assays are performed use

the following test doses per ml; Amphotericin B, 1.0 to 4.0 μg; Bacteracin, 1.0 to 4.0 Units; Kanamycin

Sulphate, 5.0 to 20.0 units; Streptomycin, 5.0 to 20.0 μg.

[Adapted

From : Indian Pharmacopoea. Vol. II,

1996] 10.6.1.4.

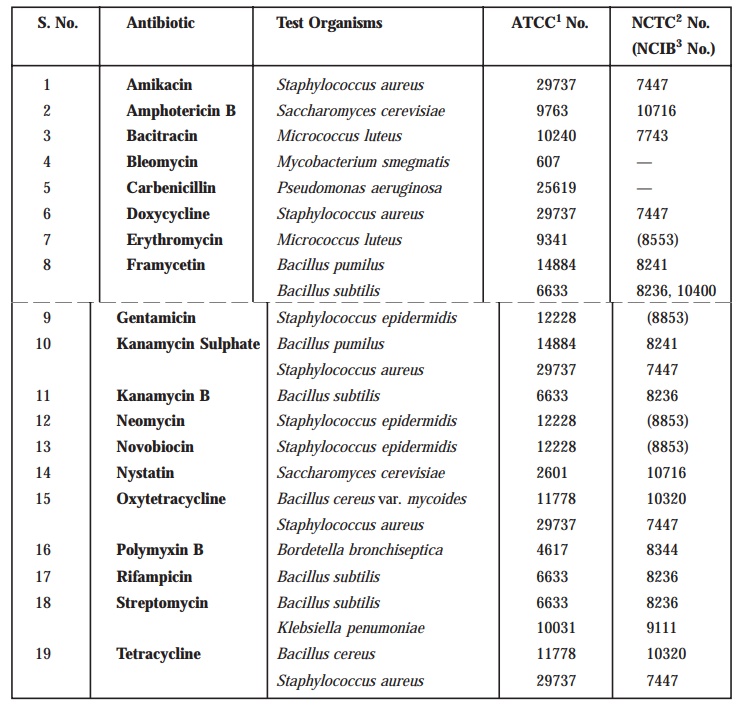

Test Organisms

The

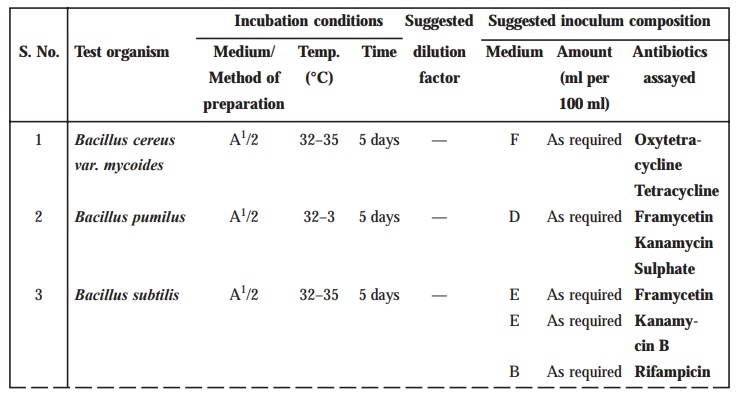

various test organisms for each antibiotic is duly listed in Table

10.4, along with its prop-erly documented identification

number in the following recognized and approved compendia as :

·

American Type Culture Collection (ATCC)

·

National Collection of Type Cultures (NCTC)

·

National Collection of Industrial Bacteria (NCIB).

Usually

maintain a ‘culture’ on the slants

of the medium, and under the specified incubation

conditions as mentioned duly in

Table 10.5, and transfer weekly to fresh slants.

TABLE 10.4 : Test Organisms for Microbiological

Assays of Antibiotics

·

American Type Culture Collection, 21301 Park Lawn

Drive, Rockville, MD 20852, USA.

·

National Collection of Type Cultures, Central

Public Health Laboratory, Colindale Avenue, London NW9 5HT, England.

·

National Collection of Industrial Bacteria, Torry

Research Station, P.O. Box 31, 135 Abbey Road, Aberdeen 98 DC, Scotland.

[Adapted

From : Indian Pharmacopoea, Vol. II,

1996]

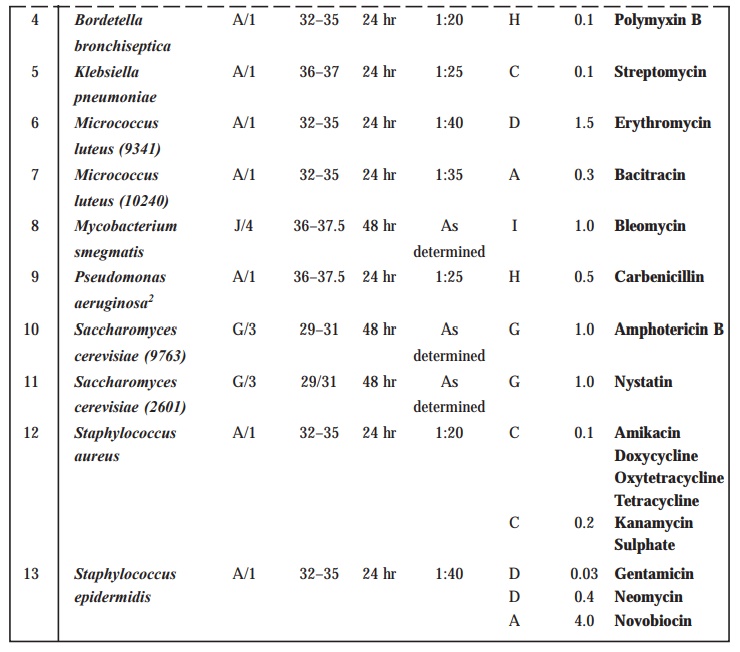

TABLE 10.5 : Preparation of Inoculum

Methods of preparation of test organism suspension

1. Maintain

the test organism on slants of Medium A and transfer to a fresh slant once a

week. Incubate the slants at the temperature indicated above for 24 hours.

Using 3 ml of saline solution, wash

the organism from the agar slant onto a large agar surface of Medium A such as

a Roux bottle containing 250 ml of agar. Incubate for 24 hours at the

appropriate temperature. Wash the growth from the nutrient surface using 50 ml

of saline solution. Store the test

organism under refrigeration. Determine the dilution factor which will give 25%

light transmission at about 530 nm. Determine the amount of suspensions to be

added to each 100 ml of agar of nutrient broth by use of test plates or test

broth. Store the suspension under refrigeration.

2. Proceed

as described in Method 1 but incubate the Roux bottle for 5 days. Centrifuge

and decant the supernatant liquid. Resuspend the sediment with 50 to 70 ml of saline solution and heat the suspension

for 30 minutes at 70°. Wash the spore suspension three times with 50 to 70 ml

of saline solution. Resuspend in 50

to 70 ml of saline solution and

heat-shock again for 30 minutes. Use test plates to determine the amount of the

suspension required for 100 ml of agar. Store the suspension under

refrigeration.

3. Maintain

the test organism on 10 ml agar slants of Medium G. Incubate at 32° to 35° for

24 hours. Inoculate 100 ml of nutrient broth. Incubate for 16 to 18 hours at

37° and proceed as described in Method 1.

4. Proceed

as described in Method 1 but wash the growth from the nutrient surface using 50

ml of Medium 1 (prepared without agar) in place of saline solution.

[Adapted

From : Indian Pharmacopoea, Vol. II,

1996]

Preparation of Inoculum

The

method of preparation of the microbial

suspensions for preparing the inoculum for the assay of various antibiotics is clearly stated in Table 10.5. In an

event when the suspensions are duly prepared

by these methods, one may accomplish and observe that the growth characteristic

features are fairly uniform in order that the inoculum could be determined by

carrying out the following trials.

For Method A. After the suspension is prepared,

as given under Table 10.5, add different

volumes of it to each of several different flasks containing 100 ml of the

medium specified in Table 10.4 (the volume of suspension suggested in Table

10.4 may be used as a guide). Using these inocula, prepare inoculated plates as

described for the specific antibiotic assay. While conducting cylin-der-plate

assays, double layer plates may be prepared by pouring a seed layer (inoculated

with the desired micro-organism) over a solidified uninoculated base layer. For

each Petri dish, 21 ml of the base layer and 4 ml of the seed layer may be

generally suitable. Fill each cylinder with the median concentra-tion of the

antibiotic (Table 10.4) and then incubate the plates. After incubation, examine

and measure the zones of inhibition. The volume of suspension that produces the

optimum zones of inhibition with respect to both clarity and diameter

determines the inoculum to be used for the assay.

For Method B. Proceed as descirbed for Method A

and, using the several inocula, carry

out the procedure as described for the specific antibiotic assay running only

the high and low con-centrations of the standard response curve. After

incubation, read the absorbances of the appropriate tubes. Determine which

inoculum produces the best response between the low and high antibiotic

con-centrations and use this inoculum for the assay.

Apparatus. All equipment is to be thoroughly

cleaned before and after each use. Glassware for holding and transferring test organisms is sterilised by dry heat

or by steam.

Temperature Control

Thermostatic

control is required in several stages of a microbial assay, when culturing a

micro-organisms and preparing its inoculum and during incubation in a plate

assay. Closer control of the temperature is imperative during incubation in a

tube assay which may be achieved by either circulated air or water, the greater

heat capacity of water lending it some advantage over circulating air.

Spectrophotometer

Measuring

transmittance within a fairly narrow frequency band requiers a suitable

spectrophotometer in which the wavelength of the light source can be varied or

restricted by the use of a 580 nm filter

for preparing inocula of the required density, or with a 530 nm filter for reading the absorbance in a tube assay. For the

latter purpose, the instrument may be arranged to accept the tube in which

incubation takes place, to accept a modified cell fitted with a drain that

facilitates rapid change of contents, or preferably fixed with a flow-through

cell for a continuous flow-through analysis. Set the instrument at zero

absorbance with clear, uninoculated broth prepared as specified for the

particular antibiotic, including the same amount of test solution and

formaldehyde as found in each sample.

Cylinder-Plate Assay Receptacles

Use

rectangular glass trays or glass or plastic Petri dishes (approximately 20 ×

100 mm) having covers of suitable material and assay cylinders made of glass,

porcelain, aluminium or stainless steel with outside diameter 8 mm ± 0.1 mm,

inside diameter 6 mm ± 0.1 mm and length 10 mm ± 0.1 mm. Instead of cylinders,

holes 5 to 8 mm in diameter may be bored in the medium with a sterile borer, or

paper discs of suitable quality paper may be used. Carefully clean the

cylinders to remove all residues. An occasional acid-bath, e.g., with about 2M nitric

acid or with chromic acid solution

is needed.

Turbidimetric Assay Receptacles

For assay

tubes, use glass or plastic test-tubes, e.g.,

16 mm × 125 mm or 18 mm × 150 mm that are relatively uniform in length,

diameter, and thickness and substantially free form surface blemishes and

scratches. Cleanse thoroughly to remove all antibiotic residues and traces of

cleaning solution and sterilise tubes that have been used previously before

subsequent use.

Assay Designs

Microbial

assays gain markedly in precision by the segregation of relatively large

sources of potential error and bias through suitable experimental designs. In a

cylinder-plate assay, the essential comparisons are restricted to relationships

between zone diameter measurements within plates, exclu-sive of the variation

between plates in their preparation and subsequent handling. To conduct a

turbidimetric assay so that the difference in observed turbidity will reflect

the differences in the antibi-otic concentration requires both greater

uniformity in the environment created for the tubes through closer thermostatic

control of the incubator and the avoidance of systematic bias by a random

placement of replicate tubes in separate tube racks, each rack containing one

complete set of treatments. The essential comparisons are then restricted to

relationships between the observed turbidities within racks.

Within

these restrictions, two alternative designs are recommended; i.e., a 3-level (or 2-level) factorial

assay, or a 1-level assay with a standard curve. For a factorial assay, prepare

solutions of 3 or 2 corresponding test dilutions for both the standard and the

unknowns on the day of the assay, as described under Preparation of the

Standard and Preparation of the Sample. For a 1-level assay with a standard

curve, prepare instead solutions of five test dilutions of the standard and a

solution of a single median test level of the unknown as described in the same

sections. Consider an assay as preliminary if its computed potency with either

design is less than 60% or more than 150% of that assumed in preparing the

stock solution of the unknown. In such a case, adjust its assumed potency

accordingly and repeat the assay.

Microbial

determinations of potency are subject to inter-assay

variables as well as intra-assay

variables, so that two or more

independent assays are required for a reliable estimate of the potency of a given assay preparation or unknown.

Starting with separately prepared stock solutions and test dilutions of both

the standard and the unknown, repeat the assay of a given unknown on a

different day. If the estimated potency of the second assay differs

significantly, as indicated by the calculated standard error, from that of the

first, conduct one or more additional assays. The combined result of a series

of smaller, independent assays spread over a number of days is a more reliable

estimate of potency than that from a single large assay with the same total

number of plates or tubes.

Methods.

The microbiological assay of antibiotics may

be carried out by Method A or Method B.

[A] Cylinder-Plate or Cup-Plate Method

Inoculate

a previously liquefied medium appropriate to the assay (Tables 10.1 and 10.3)

with the requisite quantity of suspension of the micro-organisms, add the

suspension to the medium at a tempera-ture between 40° and 50° and immediately

pour the inoculated medium into Petri dishes or large rectan-gular plates to

give a depth of 3 to 4 mm (1 to 2 mm for nystatin).

Ensure that the layers of medium are uniform in thickness, by placing the

dishes or plates on a level surface.

The

prepared dishes or plates must be stored in a manner so as to ensure that no

significant growth or death of the test organism occurs before the dishes or plates

are used and that the surface of the agar layer is dry at the time of use.

Using the

appropriate buffer solutions indicated in Tables 10.2 and 10.3, prepare

solutions of known concentration of the Standard Preparation and solutions of

the corresponding assumed concen-trations of the antibiotic to be examined.

Where directions have been given in the individual monograph for preparing the

solutions, these should be followed and further dilutions made with buffer

solution as indicated in Table 10.3. Apply the solutions to the surface of the

solid medium in sterile cylinders or in cavities prepared in the agar. The

volume of soluiton added to each cylinder or cavity must be uniform and

sufficient almost to fill the holes when these are used. When paper discs are

used these should be sterilised by exposure of both sides under a sterilising

lamp and then impregnated with the standard solutions or the test solutions and

placed on the surface of the medium. When Petri dishes are used, arrange the

solutions of the Standard Preparation and the antibiotic to be examined on each

dish so that they alternate around the dish and so that the highest

concentrations of standard and test preparations are not adjacent. When plates

are used, place the solutions in a Latin square design, if the plate is a

square, or if it is not, in a randomised block design. The same random design

should not be used repeatedly.

Leave the

dishes or plates standing for 1 to 4 hours at room temperature or at 4°, as

appropriate, as a period of pre-incubation diffusion to minimise the effects of

variation in time between the applica-tion of the different solutions. Incubate

them for about 18 hours at the temperature indicated in Table 10.3. Accurately

measure the diameters or areas of the circular inhibition zones and calculate

the results.

Selection

of the assay design should be based on the requirements stated in the

individual mono-graph. Some of the usual assay designs are as follows.

[A.1] One-Level Assay with Standard Curve

Standard solution. Dissolve

an accurately weighted quantity of the Standard Preparation of the antibiotic, previously dried where

necessary, in the solvent specified in Table 10.3, and then dilute to the

required concentration, as indicated, to give the stock solution. Store in a

refrigerator and use within the period indicated. On the day of the assay,

prepare from the stock solutions, 5 dilutions (solutions S1 to S5)

representing five test levels of the standard and increasing stepwise in the

ratio of 4 : 5. Use the dilution specified in Table 10.3 and a sequence such

that the middle or median has the concentration given in the table.

Sample solution. From the information available

for the antibiotic preparation which is being examined (the “unknown”) assign to it an assumed potency per unit

weight or volume and on this assumption prepare on the day of the assay a stock

solution with the same solvent as used for the standard. Prepare from this

stock solution a dilution to a concentration equal to the median level of the standard

to give the sample solution.

Method. For preparing the standard curve,

use a total of 12 Petri dishes or plates to accommo-date 72 cylinders or

cavities. A set of three plates (18 cylinders or cavities) is used for each

dilution. On each of the three plates of a set fill alternate cylinders or

cavities with solution S3 (representing the median concentration of

the standard solution) and each of the remaining 9 cylinders or cavities with

one of the other 4 dilutions of the standard solution. Repeat the process for

the other 3 dilutions of the standard solutions. For each unknown preparation

use a set of three plates (18 cylinders or cavities) and fill alternate

cylinders or cavities with the sample solution and each of the remaining 9

cylinders of cavities with solution S3.

Incubate

the plates for about 18 hours at the specified temperature and measure the

diameters or the zones of inhibition.

Estimation of potency. Average

the readings of solution S3 and

the readings of the concentra-tion tested on each set of three plates, and

average also all 36 readings of solution S3. The average of the 36

readings of soluiton S3 is the correction point for the curve.

Correct the average value obtained for each concentration (S1, S2,

S4 and S5) to the figure it would be if the readings for

solution S3 for that set of three plates were the same as the

correction point. Thus, in correcting the value obtained with any

concentration, say S1, if the average of 36 readings of S3

is, for example, 18.0 mm and the average of the S3 concentrations on

one set of three plates is 17.8 mm, the correction is + 0.2 mm. If the average

reading of S1 is 16.0 mm, the corrected reading of S1 is

16.2 mm. Plot these corrected values including the average of the 36 readings

for solutions S3 on two-cycle semilog paper, using the

concentrations in Units or μg per ml

(as the ordinate logarithmic scale) and the diameter of the zones of inhibition

as the abscissa. Draw the straight response line either through these points by

inspection or through the points plotted for highest and lowest zone diameters

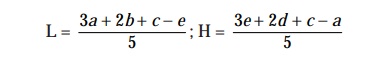

obtained by means of the following expressions :

L =

[ 3a + 2b + c – e] / 5 ; H = [ 3e + 2d + c – a]

/5

where

L = the

calculated zone diameter for the lowest concentration of the standard curve

response line.

H = the

calculated zone diameter for the highest concentration of the standard curve

response line.

c = average zone diameter of 36

readings of the reference point standard solution.

a, b, d, e = corrected average values for the

other standard solutions, lowest to highest

concentrations, respectively.

Average

the zone diameters for the sample solution and for solutions S3 on

the plates used for the sample soluiton. If the sample gives a large average

zone size than the average of the standard (solution S3), add the

difference between them to the zone size of solution S 3 of the

standard response line. If the average sample zone size is smaller than the

standard values, subtract the difference between them from the zone size of

solution S3 of the standard response line. From the response line

read the concentration corresponding to these corrected values of zone sizes.

From the dilution factors the potency of the sample may be calculated.

[A.2] Two-Level Factorial Assay

Prepare

parallel dilutions containing 2 levels of both the standard (S1 and

S2) and the unkown (U1 and U2). On each of

four or more plates, fill each of its four cylinders or cavities with a

different test dilution, alternating standard and unknown. Keep the plates at

room temperature and measure the diam-eters of the zones of inhibition.

Estimation of potency. Sum the

diameters of the zones of each dilution and calculate the % potency of the sample (in terms of the standard) from the

following equation :

% potency

= Antilog (2.0 + a log I)

wherein a may have a positive or negative value

and should be used algebracially and

where a = (U1 + U2 ) –

(S1 + S2 ) / (U1 + U2) + (S1

– S2)

U1

and U2 are the sums of the zone diameters with solutions of the

unknown of high and low levels.

S1

and S2 are the sums of the zone diameters with solutions of the

standard of high and low levels.

I = ratio

of dilutions.

If the

potency of the sample is lower than 60% or greater than 150% of the standard,

the assay is invalid and should be repeated using higher or lower dilutions of

the same solutions. The potency of the sample may be calculated from the

expression.

[ % potency

× assumed potency of the sample ] / 100

[A.3] Other Designs

(1) Factorial

assay containing parallel dilution of three test levels of standard and the

unknown.

(2) Factorial

assay using two test levels of standard and two test levels of two different

un- knowns.

[B] Turbidimetric or Tube Assay Method

The

method has the advantage of a shorter

incubation period for the growth of the test organism (usually 3 to 4

hours) but the presence of solvent residues or other inhibitory substances

affects this assay more than the cylinder-plate assay and care should be taken

to ensure freedom from such sub-stances in the final test solutions. This

method is not recommended for cloudy or turbid preparations.

Prepare

five different concentrations of the standard solution for preparing the

standard curve by diluting the stock solution of the Standard Preparation of

the antibiotic (Table 10.3) and increasing stepwise in the ratio 4 : 5. Select

the median concentration (Table 10.3) and dilute the solution of the substance

being examined (unknown) to obtain approximately this concentration. Place 1 mL

of each concentration of the standard solution and of the sample solution in

each of the tubes in duplicate. To each tube add 9 ml of nutrient medium (Table

10.3) previously seeded with the appropriate test organ-ism (Table 10.3).

At the

same time prepare three control tubes, one containing the inoculated culture

medium (cul-ture control), another identical with it but treated immediately

with 0.5 mL of dilute formaldehyde

solu-tion (blank) and a third containing uninoculated culture medium.

Place all

the tubes, randomly distributed or in a randomized block arrangement, in an

incubator or a water-bath and maintain them at the specified temperature (Table

10.3) for 3 to 4 hours. After incubation add 0.5 mL of dilute formaldehyde solution to each tube. Measure the growth of

the test organism by determining the absorbance

at about 530 nm of each of the solutions in the tubes against the blank.

Estimation of potency. Plot the

average absorbances for each concentration of the standard on semi-logarithmic

paper with the absorbances on the arithmetic scale and concentrations on

the logarith-mic scale. Construct the best straight response line through the

points either by inspection or by means of the following expressions :

where

L = the

calculated absorbance for the lowest concentration of the standard response

line.

H = the

calculated absorbance for the highest concentration of the standard response

line.

a, b, c, d, e = average absorbance values for

each concentration of the standard response line lowest to highest

respectively.

Plot the

values obtained for L and H and connect the points. Average the absorbances for

the sample and read the antibiotic concentration from the standard response

line. Multiply the concentration by the appropriate dilution factors to obtain

the antibiotic content of the sample.

Precision of Microbiological Assays

The

fiducial limits of error of the estimated potency should be not less than 95%

and not more than 105% of the estimated potency unless otherwise stated in the

individual monograph. This degree of precision is the minimum acceptable for

determining that the final product complies with the official requirements and

may be inadequate for those deciding, for example, the potency which should be

stated on the label or used as the basis for calculating the quantity of an

antibiotic to be incorporated in a preparation. In such circumstances, assays

of greater precision may be desirable with, for instance, fiducial limits of

error of the order of 98% to 102%. With this degree of precision, the lower

fiducial limit lies close to the estimated potency. By using this limit,

instead of the estimated potency, to assign a potency to the antibiotic either

for labelling or for calculating the quantity to be included in a prepara tion,

there is less likelihood of the final preparation subsequently failing to comply

with the official requirements for potency.

Related Topics