Cell Kinetics

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Bioprocessing

The principles of bioreactor design require understanding the phenomena intended to take place in these controlled environments.

CELL KINETICS

Definitions

The

principles of bioreactor design require understanding the phenomena intended to

take place in these controlled environments. This relates to the growth

kinetics of prokaryotic or eukaryotic cells derived from animal, plant, or

microbial origins. The complexity of biochemical reactions and transport

phe-nomena render accurate predictive mathematical modeling impossible since

the system consists of multiple phases having many components. Attempts have

been made to estimate growth kinetics based on a matrix combining unstruc-tured

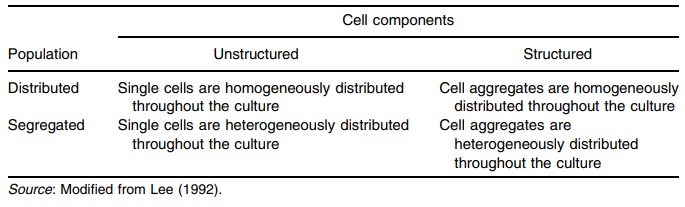

or structured approaches to distributed or segregated models (Table 16.2).

Growth Cycle

The

growth cycle of cells has been documented for over a century. It consists of

six phases that describe cells growth from an initial period of accommodation

or acclimatization through to exhaustion or overpopulation of the environment.

The lag phase, which occurs when cells are introduced into a medium, is a

period of time when no net change in cell number occurs. This phase is followed

by an accelerated growth phase when the cell numbers start to increase and the

division rate increases to reach a maximum in the exponential growth phase,

where the division rate is proportional to dln Cn0/dt, which is

constant at maximum value. Following this maximal growth rate, a deceleration

in both growth and division occurs. The cell population finally reaches a

maximum value, but the death of growing cells occurs as nutrients are depleted.

TABLE 16.2 Various Models for Cell Kinetics

Monod Kinetic Parameters

Much

has been written regarding the growth of cells in fermenters and chemostats

(Lee, 1992). The kinetic considerations in these systems are briefly summarized

below.

The

Monod equation is an empirical expression describing the effect of substrate

concentration on the specific growth rate, and it takes a form similar to

Michaelis–Menton enzyme kinetics or the Langmuir adsorption isotherm:

where

μ and μ max are growth rate and

specific growth rate at half-maximum value, and Ks and Cs

are a system coefficient and concentration of the limiting substrate in the

medium, respectively.

Monod

kinetic parameters specific growth rate at half-maximum and the system

coefficient cannot be estimated with a series of individual studies as easily

as Michaelis–Menton kinetics for enzyme action. The initial reaction rate can

be measured accurately as a function of substrate concentration for enzymes.

Cell cultures undergo an initial lag phase in growth in which Monod kinetics do

not apply. Even though the Monod equation has the same form as the

Michaelis–Menton equation, the rate equation is different.

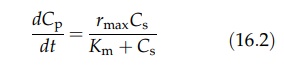

The

Michaelis–Menton equation describing enzyme activity takes the form

where

Cp and Cs are product concentration and substrate

concentration, respectively, and Km is the rate constant. The Monod

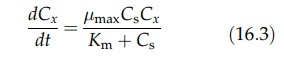

equation takes the form

Note

that the cell concentration term Cx in the Monod equation is absent

from the Michaelis–Menton equation.

Measuring

the steady-state substrate concentration at various flow rates, one can test

various kinetic models and estimate the value of the kinetic parameters.

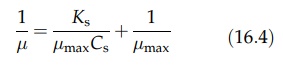

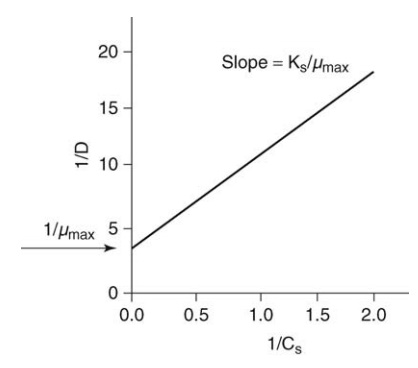

A

linear relationship can be derived as follows:

where

μ is equal to the

dilution rate (D) for a chemostat. If a certain microorganism follows Monod

kinetics, the plot of 1/ μ

versus l/Cs yields the values of μ max and Ks

by reading the intercept and the slope of the straight line. This plot is the

same as the Lineweaver–Burk plot for Michaelis–Menton kinetics. Since 1/ μ approaches infinity as the

substrate concentration decreases, the data is weighted too heavily at low

substrate concentrations and insuffi-ciently at high substrate concentrations.

Nevertheless, this approach has the advantage of showing the relationship

between the independent (Cs) and dependent variables (μ). Figure 16.1 illustrates the

manner in which the specific growth rate may be derived from a plot of

reciprocal dilution rate versus reciprocal substrate rate.

FIGURE 16.1 Reciprocal dilution rate for a

chemostat plotted against reciprocal substrate concentration.