Facilities and equipment

| Home | | Hospital pharmacy |Chapter: Hospital pharmacy : Technical services

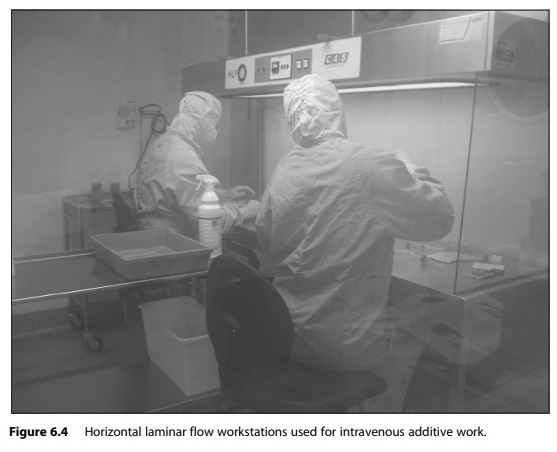

All aseptic manipulation must take place in EU grade A work zones. These can be provided by horizontal or vertical laminar air flow cabinets or positive-pressure isolators.

Facilities and equipment

All aseptic

manipulation must take place in EU grade A work zones. These can be provided by

horizontal or vertical laminar air flow cabinets or positive-pressure

isolators. For hazardous drugs, such as cytotoxics and radiopharma-ceuticals,

the use of a negative-pressure isolator is recommended to provide protection

not only to the product, but also the operator(s). The grade A workstation must

be located in a controlled background environment, usually of EU grade B,

although some isolators may be located in an EU grade C or D background. Figure

6.4 shows horizontal laminar flow workstations used for IV additive work.

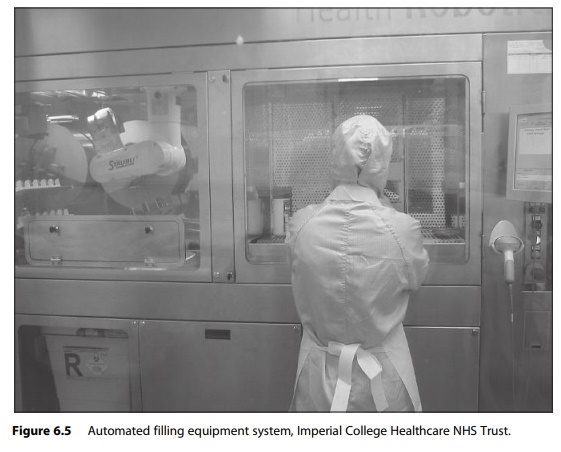

Automated filling

equipment may be placed in the critical work zone providing it is fully

validated. Figure 6.5 shows an automated system.

The Rules and

Guidance for Good Pharmaceutical Manufacture and Distribution and Quality

Assurance of Aseptic Preparation Services should be consulted for exact

standards and requirements of facilities and equipment. Specialist guidance on

isolator technology is also available.

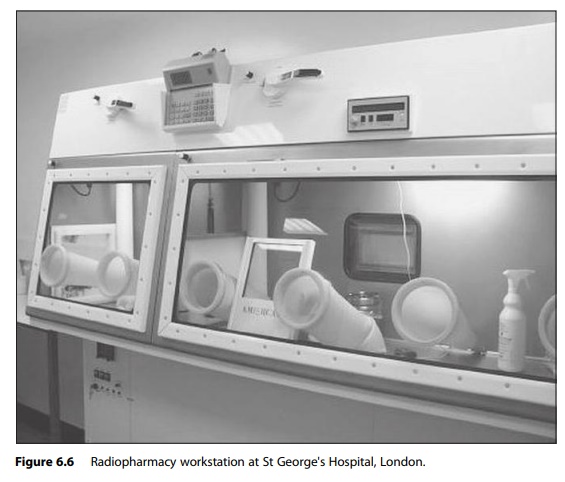

In addition to the

critical aseptic handling areas, areas must be desig-nated for setting up

ingredients, producing batch documents and labels, and checking and packing the

finished product. Handling radiopharmaceuticals requires additional equipment

to protect the operator from ionising radia-tion and to monitor exposure

levels. Also, tandem isolator systems are necessary to include the technetium

(Tc99) generator in the controlled work area (Figure 6.6). Operators are required

to wear body badges and finger badges in order to quantify the amount of

exposure they have received. They must also follow systems of work which

control exposure by either mini-mising the time spent directly exposed to the

source of radiation or by maximising the distance from it. Such practices

include working behind lead glass shields and the use of syringe and vial

shields and lead housing for generators. These shields must also be

accommodated within the isolator or class 2 cabinet workstation. Tongs are used

to increase the distance between the operator and the doses. Dose monitors are

also used to check for spil-lages and contamination and are subsequently used

to ensure such incidents are cleared up appropriately. There are specific

elements of operator training which must be covered besides the routine

pharmacy training. There are also local rules which must be read which cover

the safe systems of working with radiation. The introduction of the robotic arm

for manipulation of radio-pharmaceuticals should further increase operator

safety.

Process

Wherever possible,

all aseptic processes should be based on closed systems so that the product or

the product fluid path has only minimal exposure to the environment. Product

segregation is essential to prevent gross contamin-ation and separate clean

rooms and workstations should be used for cytotoxic drugs and

radiopharmaceuticals. Operator technique is critical and all opera-tors, processes

and equipment must be fully validated.

The manipulation of

cytotoxic drugs requires additional protective cloth-ing and emergency

procedures for spillage management. These are detailed in non-official UK

guidelines. To avoid aerosol formation, venting nee-dles and filters or

purpose-designed fluid transfer devices must be used when adding and

withdrawing liquids to and from vials. In the case of aseptic products,

environmental monitoring and the use of routine media-fill simula-tions are

more meaningful than sterility tests, which are designed to be used with

terminally sterilised medicines. Support from an experienced QA depart-ment is

essential not only for the validation of all aseptic processes but also for

formulation and shelf-life issues with aseptic preparations. The addi-tional

risks associated with unintentional intrathecal administration of cer-tain

cytotoxic agents have led to additional guidance on the presentation, process

and release of these products. With a few exceptions, all vinca alkal-oid doses

must now be presented as large-volume infusions (50 ml) to prevent the lethal

intrathecal administration of these drugs.

The processes

involved in the preparation of radiopharmaceuticals require consideration of

additional issues, including the prescribing and scheduling doses, which are

often complex. Most doctors who request scans are not authorised to prescribe

radioactive pharmaceuticals. Requests must therefore be authorised by the local

Administration of Radioactive Substances Advisory Committee licence holder

before they can be scheduled into the nuclear medicine clinic. To maximise the

scanning capacity of a nuclear medicine department, doses need to be ready at

the beginning of the working day. An on-site radiopharmacy can help facilitate

this and enable the service to be more flexible when responding to urgent

requests. In contrast to routine CIVAS work, radiopharmacy staff start dose

preparation first thing in the morning and early starts of 7 a.m. are not

unusual. Reconstitution of kits requires the addition of a radionuclide and

saline to a ligand contained in a sterile vial. The resulting solution may need

to be incubated for a set period to ensure the radionuclide has attached to the

ligand. Simple QC analysis can be performed to confirm the radiochem-ical

purity of the radiopharmaceutical. Poor-quality radiopharmaceuticals may expose

patients to radiation unnecessarily and their treatment may be delayed while

the investigation is repeated.

Related Topics