Non-sterile manufacture

| Home | | Hospital pharmacy |Chapter: Hospital pharmacy : Technical services

The manufacture of traditional non-sterile oral liquids and topical prep-arations, usually in accordance with British Pharmaceutical Codex formulae, has declined in the hospital sector over recent years.

Non-sterile manufacture

Scope

The manufacture of

traditional non-sterile oral liquids and topical prep-arations, usually in

accordance with British Pharmaceutical Codex formulae, has declined in the

hospital sector over recent years. This is largely due to the commercial

availability of licensed products and also the growth of non-sterile specials

manufacturing services operated commercially. How-ever, a non-sterile

production service is still required to support several clinical specialties,

particularly dermatology and paediatric. Many dermatol-ogists have their own

variants of standard preparations, often differing only in the type of diluents

or base used or in the concentration of active components. Although there is

little scientific evidence to support the use of these non-standard

preparations, custom, practice and clinical experience have, until recently,

provided a continuing demand. Attempts are being made to reduce the range of

products used to allow standardisation and simplification. The British

Association of Dermatologists’ preferred list was issued in 2008 to support

this approach.

Conversely, the

clinical justification for using medicines outside their licensed indications

for adults in the paediatric setting is well accepted. The unit dose of

commercially available preparations of medicines designed for adult use is

usually too large for paediatrics. Also, some of the larger tablets and

capsules would be difficult for children to swallow. Safe and reproducible

paediatric dosing therefore requires preparations of lower dose, usually in the

form of oral liquids, suspensions or powders.

Department of Health

information reported in 2002 suggested that dermatology preparations (coal tar,

salicylic acid and dithranol) were the most frequently prepared non-sterile

products by hospital pharmacy depart-ments, although in recent years most of

these preparations have become commercially available. Some hospitals have

developed commercial non-sterile manufacturing units to supply other hospitals

and community phar-macies. This type of activity helps to offset the costs of

maintaining facilities of a high standard and meeting the regulatory

requirements of MHRA specials licences.

In some hospitals,

dispensary services have been reorganised and extem-poraneous dispensing work

has been transferred to the technical services section. A wide range of

non-commercially available extemporaneous prep-arations is required for

individual patients, including oral liquids, creams, ointments, powders,

suppositories and pessaries. This approach provides variety and clinical

interest for manufacturing staff and ensures that extem-poraneous products are

produced in accordance with the principles of good manufacturing practice.

Facilities and equipment

Typically, non-sterile

manufacture is carried out in a European Union (EU) grade D environment with a

single stage change. Although some units require production staff to wear

sterilised coverall gowns, most centres rely on clean two-piece gowns of

low-lint-shedding material, over-shoes, hats and gloves. To reduce the

microbiological bioburden, drains and potable water supplies are excluded from

production areas and all surfaces should have a smooth impervious finish to

facilitate effective cleaning. Weighing areas should be separate from the main

production area (linked to it with a pass-through hatch) and should be fitted

with localised dust extraction. Although containers for non-sterile products

are not reused, a facility for washing and drying containers before use may be

required. Separate areas should be provided for labelling and reinspection of

products.

The Rules and

Guidance for Good Pharmaceutical Manufacture and Distribution strongly

recommend the use of stainless-steel measures and mixing vessels to avoid the

risk of contaminating product with spicules from glass equipment.8

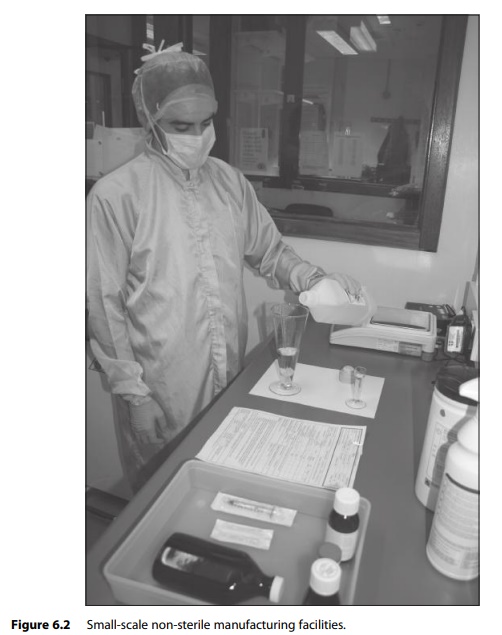

Large-scale manufacture will require the use of industrial mixers and

homogenisers. Automated liquid filling lines may be deployed for large-scale

liquid handling and some units with a significant output of creams and

ointments have also invested in tube-filling and seal-ing equipment. Figure 6.2

illustrates small-scale non-sterile manufacturing facilities.

Process

All raw materials,

containers and labels used in the production process must be approved by the

person responsible for QC. To reduce the micro-biological bioburden, limits are

placed on the level of microbiological contamination of raw materials and only

sterile water (usually water for irrigation BP) or freshly distilled water is

used for manufacture. All prod-uct formulae, storage conditions and shelf-life

assignments require prior QC approval.

The manufacturing

process is controlled through the use of approved standard operating procedures

and batch documents. Particular care is re-quired to ensure that mixing

processes produce a homogeneous product for distribution into the individual

containers that constitute the batch. This process must be validated for each

product type to ensure uniformity of content in the finished batch. The

avoidance of cross-contamination between different products is also essential.

Only one batch may be prepared in a designated work area at any one time and

the cleaning of equipment and work surfaces must be carefully validated and

monitored.

Filled containers

should be visually inspected for product homogeneity and the absence of any

extraneous matter. The security of container closures should be checked and the

quality and accuracy of labels determined against a master label for the

product. It is essential that the batch documentation includes reconciliation

between the amounts of raw materials, number of containers and number of labels

used in the process and the yield of finished product. All variations must be

recorded and investigated.

Although some

regulators have attempted to discourage non-sterile manufacturing in hospital

pharmacies, there are compelling reasons why sufficient capacity in this

activity is retained. The ongoing need for paedi-atric doses of both new and

existing medicines that are commercially avail-able in adult doses must be

recognised. There is also a requirement to formulate medicines for patients

with particular clinical needs, such as patients with dysphagia. It is

preferable for these medicines to be produced by trained pharmacy staff in

appropriate facilities, using fully documented procedures, than to have

undocumented manipulation taking place in clinical areas by nursing staff.