Sterile manufacture

| Home | | Hospital pharmacy |Chapter: Hospital pharmacy : Technical services

All terminally sterilised medicines produced in hospitals are made under a manufacturer’s specials licence, except in a few cases where PLs have been obtained.

Sterile manufacture

Scope

All terminally

sterilised medicines produced in hospitals are made under a manufacturer’s

specials licence, except in a few cases where PLs have been obtained. The range

of products made generally reflects gaps in the portfolio of licensed products

available from the pharmaceutical industry. The limited number of specialist

sterile manufacturing units remaining in the NHS pro-vides an essential service

in making available sterile parenteral and topical products that are not

commercially viable for industry to produce. Such products include non-standard

concentrations and presentations of injections and eye drops, specialist

injectables for paediatrics, anaesthetics and palliative care, and various

sterile topical products.

In some cases, NHS

hospital sterile product units have developed prod-ucts to support pharmacy

CIVAS units. These include electrolytes for addition to TPN feeds such as

concentrated sodium chloride injection, potassium phosphate injection and zinc

sulphate injection. A range of sterile bulk solutions for filling into syringes

and other devices is also produced. These include bupivacaine injection,

morphine sulphate injec-tion and fentanyl injection. Sterile manufacture also

supports research, and small runs of experimental drugs in parenteral

formulations are prepared for clinical trial use.

The container and

filling technologies employed in hospital units encom-pass glass vials, glass

ampoules, glass bottles and polyvinyl chloride infusion bags for parenteral

products, and a variety of glass and rigid plastic containers for topical

solutions. No lyophilised presentations are available since freeze-drying

technology is beyond the scope of hospital sterile product units.

Facilities and equipment

In general, the

weighing and solution preparation areas required would be similar to those

described previously for non-sterile manufacture. However, the filling, sealing

and capping stages must be accomplished in a higher-quality environment,

usually EU grade A, to minimise particu-late contamination and reduce the

microbiological load prior to sterilisa-tion. This is usually achieved by local

laminar flow of high-efficiency particulate air-filtered air at the filling

zone. After filling and sealing, containers and their contents are sterilised

by steam in an autoclave (aque-ous solutions) or by dry heat in a hot-air oven

(non-aqueous liquids, powders). The sterilisers and associated monitoring

equipment can be located in a lower-grade environment and are normally sited so

that maintenance staff can access them without the need to enter critical

pro-duction areas.

Dedicated space for

reinspection of the finished product, labelling, pack-ing and quarantine is

also required. Regulatory requirements for sterile pro-duction facilities and

sterilising equipment are strictly defined and require extensive validation.

The design and construction of sterile manufacturing units should only be

undertaken by specialist contractors. The increasing use of automated systems,

particularly for filling, sealing and reinspecting ampoules, and the

sophistication of modern steriliser technology have con-tributed to the rapid

rise in capital and maintenance costs associated with sterile manufacturing

units. National coordination and strategic planning of new units are essential

to maximise the cost-effectiveness of these expensive but important resources.

Process

In addition to the

processes outlined under non-sterile manufacture, above, sterile production

normally includes a filtration process (for liquids) and sterilisation of the

product. These processes are critical to product quality and require rigorous

validation and control. The microbiological bioburden must be minimised,

particularly in the case of injectables, to reduce the release of bacterial

pyrogens into the product, because these will not be destroyed by

sterilisation. This is achieved by limiting the number of viable microorganisms

in starting materials and by minimising the time between preparations of the

bulk product, filling and sterilisation.

The sterilisation

cycle for each batch is clearly monitored to ensure that all containers in the

batch have received the pharmacopoeial-approved temper-ature and time

combinations. Printouts of the load temperature, usually taken at the coolest

location of the autoclave or dry-heat oven, are recorded throughout the cycle

and are scrutinised as part of the release process. Additional measures are

taken to ensure that products sterilised by autoclave or hot-air oven are not

at risk from microbial contamination of cooling water or non-sterile air,

respectively, which could enter through closures during the cooling phase of

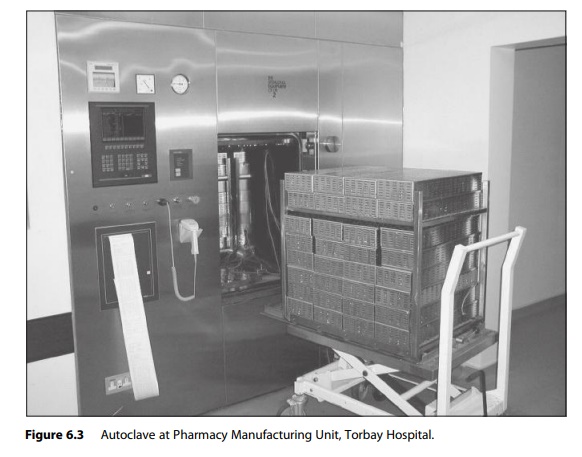

the cycle. Figure 6.3 shows an autoclave and its control systems in a large

sterile production unit.

The QC of sterile products includes analysis of active components, sterility testing, subvisual particulate measurement and tests for the absence of bac-terial pyrogens. This means that batches must be quarantined for at least 14 days (the time taken for sterility test incubation) before release. Production managers and users of sterile products need to consider this when drawing up production schedules and managing stocks.