Carboxylic Acids

| Home | | Organic Chemistry |Chapter: Organic Chemistry : Functional Group Synthesis

Carboxylic acids have a relatively high oxidation level (+3), and thus a majority of synthetic methods to access carboxylic acids are oxidative in nature.

CARBOXYLIC ACIDS

Carboxylic

acids have a relatively high oxidation level (+3), and thus a majority of synthetic

methods to access carboxylic acids are oxidative in nature. Traditional

preparations include the following:

Oxidation

of olefins

Oxidation

of primary alcohols

Oxidation

of alkylbenzenes

Hydrolysis

of nitriles

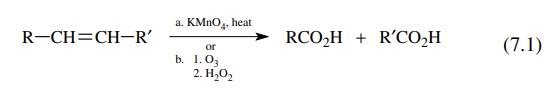

While

the above reactions will provide carboxylic acid products, each has problems

associated with it. The cleavage of olefins to carboxylic acids [reaction

(7.1)] can be carried out using potassium permanganate or by ozonolysis at low

temperature followed by oxidative workup with hydrogen peroxide. Neither of

these methods is very useful since only symmetric olefins provide a single

carboxylic acid product. Unsymmetrical olefins give a mixture of two acids

which must be separated. Furthermore the most useful synthetic processes are

those which build up structures, whereas these reactions are degradative in

nature.

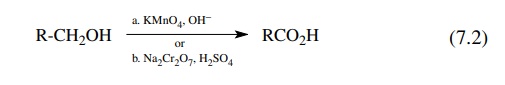

Primary

alcohols can be oxidized to carboxylic acids by a variety of reagents [reaction

(7.2)]. Often potassium permanganate or sodium dichromate were given as

reagents to use in this transformation. These are powerful oxidants, and many

other functional groups that might be present cannot survive the reaction

con-ditions. Milder oxidants are preferred and the best of these is chromic

acid in acetone (Jones reagent). Jones reagent is a mixture of chromic acid and

a stoi-chiometric amount of sulfuric acid which is needed in the redox process

to keep the solution at near a pH of 7. This technique is fast, easy, and

efficient and the reagent solution is easily prepared from chromium trioxide

and sulfuric acid in acetone. The oxidation can be carried out by adding the

Jones reagent by burette to the alcohol. Oxidation is instantaneous and the

addition can be stopped pre-cisely when all the alcohol has been consumed.

Using a stoichiometric amount of chromic acid usually leaves other functional

groups untouched. This is the method of choice for the synthesis of carboxylic

acids from primary alcohols.

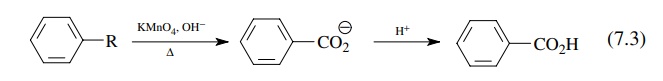

The

oxidation of alkyl benzenes to benzoic acids [reaction (7.3)] is still carried

out occasionally, and this oxidation is most likely the only one where

potassium permanganate is the reagent of choice. Any carbon group attached to

the aromatic ring is degraded to the carboxylic acid group under the very

vigorous conditions of this oxidation.

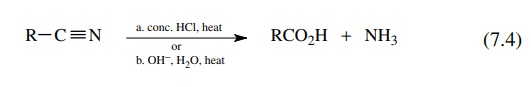

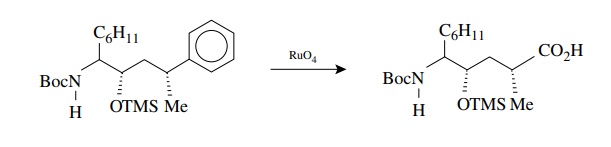

An

interesting twist on the oxidation of aromatic compounds forms the basis of a

new and very useful synthesis of carboxylic acids. Normally the aromatic ring

is resistant to oxidation and the side chains are oxidatively degraded to

car-boxylic acids, as in reaction (7.3). It has been found that ruthenium

tetroxide is a mild and selective oxidant of aromatic rings and completely

degrades the ring to the carboxylic acid but leaves aliphatic groups

unoxidized. This is essentially the reverse of the chemoselectivity seen in

potassium permanganate oxidations of arenes, where the side chains are oxidized

but the aromatic ring is left intact. The selectivity and mildness is seen in

the following example in which no amide or silyl ether (OTMS) oxidation was

observed and there was no epimerization of either chiral center:

Another

common way to install a carboxylic acid group is to hydrolyze a carboxylic acid

derivative. Such hydrolyses do not require a change in oxidation level

(carboxylic acid derivatives are at the oxidation level of the acid itself),

but they do normally require acid or base catalysis. Nitriles [reaction (7.4)]

often require vigorous conditions for hydrolysis mainly because they are only

weakly electrophilic. Either concentrated hydrochloric acid or sodium hydroxide

can be used to hydrolyze nitriles. The first stage of the hydrolysis produces

an amide and the amide is subsequently hydrolyzed to the acid. Each step of the

hydrolysis requires strenuous conditions and is useful mainly for nitriles that

lack other functional groups that would be destroyed by the stringent

conditions. It has been found that a mixture of sodium hydroxide and hydrogen

peroxide can be used to hydrolyze nitriles more efficiently than sodium

hydroxide alone and is the reagent of choice, although many other reagent

combinations have been reported.

Amides

are stabilized by resonance and are thus difficult to hydrolyze. Like nitriles

they can be hydrolyzed by concentrated hydrochloric acid or concentrated sodium

hydroxide. These are powerful reagents that tend to react with many other

functional groups as well. Thus hydrolysis is not a satisfactory method for

amides with many other functional groups present. As with nitriles, a mixture

of sodium hydroxide and hydrogen peroxide is one of the more effective reagents

for hydrolysis.

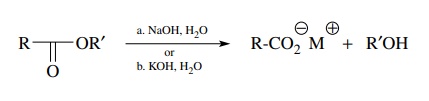

Esters,

on the other hand, are very common hydrolytic precursors to carboxylic acids.

The traditional reaction for the hydrolysis of esters is basic saponification

using sodium hydroxide or potassium hydroxide. While acid catalysis can also be

employed, preparative methods usually use base catalysis because formation of

the carboxylate salt drives the reaction to the right and gives high yields of

products.

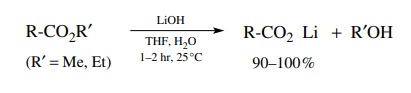

While

esters are much more easily hydrolyzed than amides, traditional saponi-fication

suffers from the fact that most esters are not soluble in aqueous base and so

the rate of the hydrolysis is limited by the solubility, not by the reactivity.

This limitation is overcome by the use of lithium hydroxide in aqueous THF, the

reagent of choice for basic hydrolysis of esters. Methyl and ethyl esters are

cleaved readily by this combination as most esters are soluble in this solvent mixture.

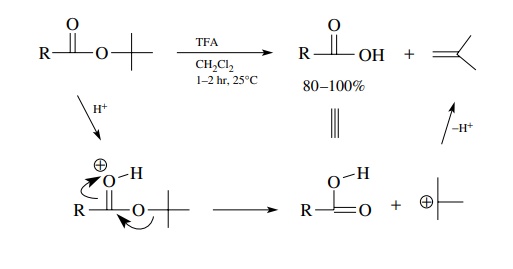

If

structural constraints prevent the use of basic hydrolysis of the ester group,

acid hydrolysis must be used. Nowadays it is much more common, in such

instances, to use tert-butyl esters

because they are cleaved rapidly and efficiently by trifluoroacetic acid (TFA)

to the carboxylic acid and isobutylene. This cleav-age is different from the

normal acid-catalyzed hydrolysis of esters in that the alkyl– oxygen bond is

broken rather than the acyl– oxygen bond. This change in mechanism is brought

about by the stability of the tert-butyl

cation which is produced upon alkyl– oxygen cleavage. As an added benefit, the

isobutylene by-product is a gas which escapes from the reaction mixture.

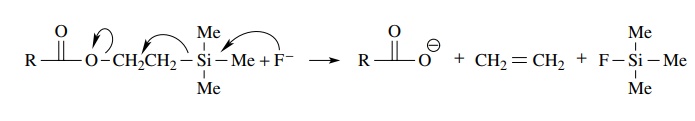

If

neither acidic nor basic conditions are compatible with other groups present in

the ester to be hydrolyzed, then β

-trimethylsilylethyl esters are often prepared. Trimethylsilylethyl esters are

cleaved easily by fluoride under mild, neutral con-ditions. Typical sources of

fluoride are cesium fluoride (CsF) or the more soluble tetrabutylammonium

fluoride (TBAF).

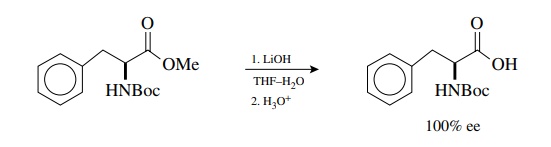

Current

methods for the hydrolysis of esters are fast, efficient, and sufficiently mild

that they are compatible with the presence of a variety of other func-tional

groups and/or stereocenters in the molecule. For example, protected amino acid

esters are hydrolyzed quantitatively without racemization or deprotection by

LiOH in aqueous THF.

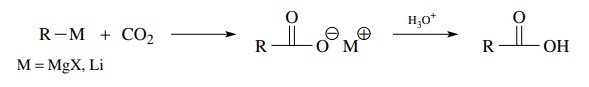

Carboxylic

acid groups can also be installed in molecules using the reaction of an

organometallic compound with carbon dioxide. This is a reductive method since

the carbon dioxide is reduced to a carboxylic acid by formation of a new

car-bon – carbon bond. Both Grignard reagents and organolithium compounds work

well in this reaction.