Devices

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Inserts, implants, and devices

Devices are specialized pharmaceutical drug delivery systems in which the desired drug delivery and targeting are achieved with the aid of the packag-ing container. Pulmonary delivery devices, transdermal devices, and IUDs exemplify them.

Devices

Devices

are specialized pharmaceutical drug delivery systems in which the desired drug

delivery and targeting are achieved with the aid of the packag-ing container.

Pulmonary delivery devices, transdermal devices, and IUDs exemplify them.

Inhaler devices for pulmonary drug delivery

Delivery

devices play a major role in the efficiency of pulmonary drug delivery. Drug

particles or solution are aerosolized and inhaled with the breath for delivery

to the lung. An aerosol is a colloidal dispersion of a liquid or a solid in a

gas. Aerosol device is a pressurized or breath-actuated dosage forms designed

to deliver the containing solution or suspension of drug(s) to the lung by

forming an aerosol at the time of administration. A pressurized aerosol device

contains a liquid propellant in a pressurizable container, a valve that allows

the pressurized product to be expelled from the container when the actuator is

pressed, and a dip tube that conveys the formulation from the bottom of the

container to the valve assembly. The propellant is a liquefied gas that expands

readily upon release of pressure to provide the driving force for the delivery

of the contents.

Formulation factors affecting pulmonary

drug delivery include par-ticle size and size distribution, shape, and density.

Generally, particles in the size range of 1–5 μm are considered respirable (have

significant lung deposition). Particle shape and density determine the

proportion of inhaled particles that deposit in deep lung alveoli versus major

airways. Device factors affecting pulmonary drug delivery include efficiency of

spray, size and size uniformity of sprayed droplets, location of spray

generation in the context of patient’s anatomy, width of spray zone, and the

speed of the aerosol. User or patient factors impacting drug delivery

to the lung include coordination of inspiration time with device actuation and

the strength, quantity, and consistency of air intake for breath-actuated

devices.

Formulation

considerations important for the development of aerosol dosage forms include uniformity of drug content, especially in the

case of powders and suspension; particle size and size distribution, shape, and

den-sity (for powders and suspensions); flow through the nozzle, compatibility

with the container components, emitted dose, and fine particle dose or fine

particle fraction in the emitted dose.

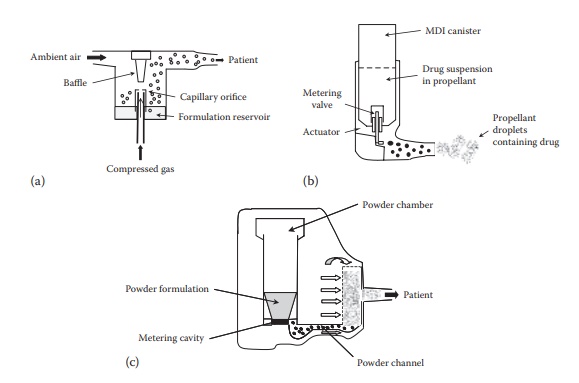

The

most commonly used devices for pulmonary drug delivery include nebulizers for

liquid formulations, metered-dose inhalers (MDIs), and dry powder inhalers

(DPIs). Figure 24.3 shows schematic of these

inhalation devices. These devices vary as much in their sophistication as they

do in their effectiveness. Each type of device has its own advantages,

disadvan-tages, and limitations. The choice of device depends on the drug (such

as solubility and stability in aqueous medium), the formulation (e.g., dry

pow-der or aqueous solution), pathophysiology of the lungs (e.g., lung

capacity), and the status of the patient (e.g., in patient or ambulatory

self-use).

Figure 24.3 An illustration of design elements of inhalation devices: (a)

nebulizer, (b) metered-dose inhaler, and (c) dry powder inhaler.

Nebulizers

Nebulizers

convert aqueous solutions or micronized suspension of a drug into an aerosol

for inhalation using compressed air (usually through a pump) and device design.

The patient inhales normally while the aero-solized product is delivered to the

patient through a mouthpiece adapter. Nebulizers require minimal patient

coordination of breathing but are cum-bersome, nonportable, and time consuming

to use.

There

are two main types of nebulizer:

·

Air-jet (high velocity air stream-aided dispersion)

nebulizers

·

Ultrasonic (ultrasonic energy-aided dispersion) nebulizers

Air-jet

nebulizers rely upon compressed gas

to aerosolize a solution that is then available for inhalation by the patient.

Ultrasonic nebulizers utilize ultrasonic vibrations for aerosolization. Both

air-jet and ultrasonic nebu-lizers produce aerosol at a constant rate

regardless of the respiration cycle. This leads to loss of approximately two

thirds of the aerosol during the expiration and breath-holding phases.

Two

improved nebulizers, the breath-enhanced

nebulizers and dosimetric nebulizers,

overcome this limitation. These inhalers direct the patient’s inhaled air

within the nebulizer to enhance aerosol volume during the inhalation phase and

release aerosol exclusively during the inhalation phase, respectively.

All

nebulizers require a solution or suspension-based formulation, which places

stringent demands on the solubility and stability of the drug in aque-ous

media. For protein and peptide drugs, the stability of proteins and peptides

upon shearing can pose additional limitation. Nebulization exerts high shear

stress on these macromolecules, which can lead to their denatur-ation. This

problem gets exacerbated because 99% of the droplets generated are recycled

back into the reservoir to be nebulized during the next dosing cycle.

Furthermore, the physical properties of drug solutions (e.g., ionic strength,

viscosity, osmolarity, pH, and surface tension) may change with dosing and may

affect the nebulization efficiency. The droplets produced by nebulizers are

heterogeneous in size, which results in very poor drug delivery to the lower

respiratory tract. They often require several minutes of use to administer the

desired dose of medicine. Nebulizers are more effective for drug delivery to

the major pathways of the respiratory track, such as the trachea, than deep

lung alveoli. Thus, adrenergic agonists such as albuterol and steroids such as

budesonide are commonly delivered by nebulizers. Recombinant human DNase,

Dornase alfa (Pulmozyme® by Genentech in South San Francisco, CA) uses

nebulizer for protein delivery to the respiratory tract. Pulmozyme reduces

viscosity of the airway secre-tions by cleaving the extracellular fibrillar

aggregates of DNA from auto-lyzing neutrophils in cystic fibrosis.

New

nebulizer devices, such as the AERx (Aradigm, Hayward, CA) and Respimat

(Boehringer, Germany), generate an aerosol mechanically and reduce the shear

forces on the drug. In addition, vibrating

mesh technolo-gies such as AeroDose (Aerogen Inc., Mountain View, CA) have

been used successfully to deliver proteins to the lungs.

Metered-dose inhalers

MDIs

generate aerosol for inhalation by expelling a measured dose of pres-surized

liquid propellant containing drug via an orifice. They are portable, easy to

use, and the most commonly used inhalation aerosol devices today. A typical MDI

comprises of a canister, metering valve, actuator, spacer, and holding chamber.

In addition, they may also have dose counters and content indicators. During

MDI manufacturing, more aerosol formulation than claimed is commonly added,

which is sufficient for additional 20–30 sprays. However, the last doses from

the container are inconsistent and unpredictable. Therefore, the dose counter

feature allows patients to track the number of actuations and avoids using the

product beyond the recom-mended number of doses.

MDIs

utilize propellants, such as chlorofluorocarbons (CFC) and hydro-fluoroalkanes

(HFAs), to emit the drug solution through a nozzle. A meter-ing chamber within

the valve measures individual doses volumetrically. High velocity of the

generated aerosol spray causes substantial oropharyn-geal deposition by

impaction, which results in poor drug delivery to the lung. This can be avoided

by adding a spacer device, which

reduces aerosol velocity. The spacer also overcomes difficulties in the

coordination of inha-lation and actuation, especially for pediatric patients,

resulting in improved dosing reproducibility.

MDI

delivery efficiency depends on the patient’s inspiratory flow rate, breathing

pattern, and hand–mouth coordination. Increase in tidal volume (volume of air

moved into or out of the lungs during normal breathing) and decrease in

respiratory frequency increase peripheral drug deposition in the lung. Most

patients need to be trained for proper use of the MDI.

Dry powder inhalers

DPIs

are one of the most popular methods of protein delivery to the lungs. DPIs

generate aerosols by drawing air through the loose dry powder of a drug

formulation. These are usually capsule-based devices, wherein the dry powder

formulation is filled and provided in a hard gelatin capsule. The device

pierces the capsule and provides inspiratory air pathway that would fluidize

the capsule and would enable release of its contents through the piercing. The

drug particles form an aerosol in the inspired air upon breath-ing by the

patient. DPIs are generally easier to use, compared to MDIs. However, DPIs

require a rapid rate of inhalation to provide necessary energy for

aerosolization, which may be difficult for pediatric or distressed patients,

and in certain disease states such as asthma or chronic obstructive pulmonary

disease (COPD). DPIs range from unit dose systems, employing only the patient’s

breath to generate the aerosol, to multiple-dosing

reser-voir devices, which actively impart energy to the powder bed to

introduce aerosol particles into the

patient’s respiratory airflow. For stability reasons, unit-dose devices are preferred for protein delivery. Figure 24.3c shows the schematic design of a noncapsule-based DPI (Novolizer®).

Lung

deposition of drug particles varies among different DPIs. DPIs are complex

systems, and their performance depends on effective powder deagglomeration.

Drugs in low doses are often combined with excipients that provide drug-binding

sites on surface while serving as bulking agents. These help with uniformity of

drug content and consistency of emitted dose. Carrier particles, such as

lactose, are commonly added to avoid drug agglomeration due to cohesive forces

among the micronized drug parti-cles. When air is directed through the powder,

turbulent airflow detaches small drug particles from the carrier particles. The

smaller particle size drug migrates to the lung alveoli, whereas the larger

particle size excipient deposits in the back of the throat and in the major

respiratory airways. Thus, optimized performance of both the device and the

formulation is critical to ensuring high and consistent lung deposition.

Most

of the therapeutic dry powders for DPIs are currently made with particles of

small aerodynamic particle diameter (e.g., 90% particles below 5 μm) and density of 1 ± 0.5 g/cm3.

Increased porosity of particles, such as when produced by spray drying, helps

with deep lung penetration by improving the aerodynamic performance. Uniformity

of particle size distri-bution, shape, and density are important for achieving

efficient pulmonary delivery.

Drugs

administered by inhalation are mostly intended to have a direct effect on the

lungs. Inhaled drugs play a very prominent role in the treat-ment of asthma.

This route has significant advantages over oral or paren-teral administration,

because lipid-soluble compounds are rapidly absorbed across the respiratory

tract epithelium. Bronchodilators and corticosteroids are commonly used for

treating asthma and COPD. Azmacort® (triamcino-lone acetamide), Ventolin® HFA

(albuterol sulfate), and Serevent® (salme-terol) are examples of commercially

available aerosols for the treatment of asthma.

Proteins,

oligonucleotides, and genes demonstrate poor oral bioavailabil-ity due to the

harsh environment of the gastrointestinal tract and their hydrophilicity, large

size, and rapid metabolism. In such cases, the pulmo-nary route enables higher

rates of passage into systemic circulation than oral administration.

Intrauterine devices

IUDs,

as the name suggests, are the devices that are placed in the uterus. These

devices are mostly used for contraception by preventing the fertilization of

the egg by the sperm, inhibiting tubular transport, and/or preventing the

implantation of the blastocyst into the uterine endometrium. The hormone

containing devices can be used for other hormonal effects such as in menorrhagia.

IUDs

can be (a) inert, (b) copper based, or (c) hormone containing. Most IUDs are T

shaped so that they are held in place in the uterus by the arms of the T shape. The copper surface of

copper-based IUDs allows the release of copper in the uterine mucosal

microenvironment, which aids contra-ception. A side effect of copper-based IUDs

is increased uterine bleeding. The hormone-based IUDs mostly contain a

progestogen. The use of these devices can provide much lower systemic and high

local progestogen levels.

·

Progestasert® device is designed for implantation into the

uterine cav-ity, where it releases 65 μg progesterone per day to provide

contracep-tion for 1 year.

·

Mirena® device, also known as the LNG-20 IUS (intrauterine

sys-tem), contains levonorgestrel. It is designed to provide an initial drug

release rate of 20 μg/day

and is used to provide contraception for up to 5 years.

Subcutaneous devices

Parenteral

drug administration is indicated for several drugs, especially the new

biotechnology-based drug products such as monoclonal antibod-ies, and protein

and peptide therapeutic agents. During the initial clinical development of

these therapies, IV route of drug administration is adopted to allow dose

flexibility and the ability to closely monitor and control drug exposure.

However, the IV route of drug administration is not preferred for commercial

use of these drugs by patients because IV drug adminis-tration requires the

intervention of a health care professional and the use of a health care

facility. In contrast, SC administration is often preferred because it can

allow for patient self-administration at home and utilizes smaller size needle,

which causes less pain at the injection site and is more patient friendly. The

development of SC dosage forms of drugs has, there-fore, gathered significant

momentum in the recent years.

At

the same time, SC delivery of several drugs is limited by the injection volume

that can be administered in the SC space (usually about 1 mL, maximum 1.5 mL),

the required dose of the drug, and the solubility of the drug in the injection

vehicle (for a soluble drug product). Based on the dose and the solubility

calculations, the required dosing volume of a drug can sometimes exceed the

usual injectable volume in the SC space. In these cases, the use of a device

for SC drug delivery can facilitate SC delivery of a drug that would otherwise

not be possible.

The

devices that can be used for SC delivery of a drug could be a syringe pump in

an inpatient setting or a patch pump in an outpatient setting.

A

syringe pump is a mechanical device that pumps the drug product through a

syringe at a low enough rate to match the absorption of the fluid from the

injected SC space. This allows higher volume of drug to be administered

subcutaneously over a prolonged period of time. The use of a syringe pump,

however, requires the patient site of drug administration to be immobilized for

the duration of drug administration. Also, the operation and calibration of the

syringe pump usually require the expertise of a health care profes-sional.

Thus, although syringe pumps can generally be used in an inpatient setting in a

hospital and during clinical trials, their use is limited for out-patient

clinical use.

SC

devices for outpatient clinical use are generally smaller, battery-operated

pumps that can be attached to the abdominal cavity and worn under the clothing.

These allow patient self-administration and the patient can have mobility

during drug administration. Such devices are exemplified by Roche’s MyDose®

device and West’s SmartDose® electronic wearable injector. The improved quality

of life and patient convenience associated with these devices provides better

patient compliance and satisfaction with the therapy.

Related Topics