Flow of Powders

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Powders

The gravity flow of powders in chutes and hoppers and the movement of powders through a constriction occur in tabletting, encapsulation, and many processes in which a powder is subdivided for packing into final containers.

FLOW OF POWDERS

The

gravity flow of powders in chutes and hoppers and the movement of powders

through a constriction occur in tabletting, encapsulation, and many processes

in which a powder is subdivided for packing into final containers. In many

cases, the accuracy of weight and dose depends on the regularity of flow. The

flow of powders is extremely complex and is influenced by many factors. A

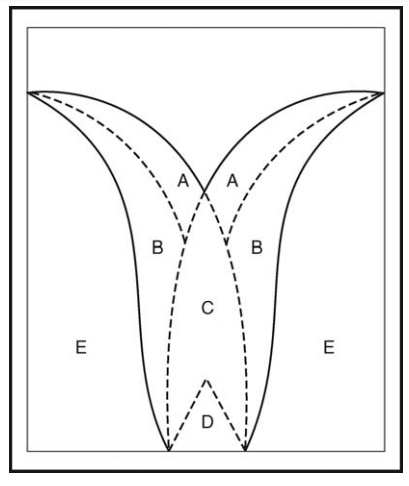

profile, in two dimensions, of the flow of granular solids through an aperture

is shown in Figure 5.3. Particles slide over A while A itself slides over B. B

moves slowly over the stationary region E. Material is fed into zone C and

moves downward and inward to a tongue D. Here, packing is less dense, particles

move more quickly, and bridges and arches formed in the powder collapse. Unless

the structure is completely emptied, powder in region E never

FIGURE 5.3 Profile of the flow of granules

through an orifice.

flows

through the aperture. If, in use, a container is partially emptied and

partially filled, this material may spoil. If the container is narrow, region E

is absent and the whole mass moves downward, the central part of region C

occupying the entire tube (Brown and Richards).

For

granular solids, the relation between mass flow rate, G, and the diameter of a

circular orifice, Do, is expressed by the equation

G =

Constant DaoHb

where

H is the height of the bed and a and b are constants. For a wide variety of

powders, the constant a lies between 2.5 and 3.0. If the height of the bed is

several times that of the orifice, H

lies between 0 and 0.05. The absence of a pressure-depth relation, already

observed in a static bed, therefore, seems to persist in dynamic conditions.

The

relation between mass flow rate and particle size is more complex. With an

orifice of given size and shape, the flow increases as the particle size

decreases until a maximum rate is reached. With further decrease in size and

increase in cohesiveness, flow decreases and becomes irregular. Arches and

bridges form above the aperture, and flow stops. The determination of the

minimum aperture through which a powder will flow without assistance is a

useful laboratory exercise. The distribution of particle sizes also affects the

flow in a given system. Often, the removal of the finest fraction will greatly improve

flow. On the other hand, the addition of very small quantities of fine powder

can, in some circumstances, improve flow. This is probably due to adsorption of

these particles onto the original material, preventing close approach and the

development of strong cohesional bonds. Magnesia and talc, for example, promote

the flow of many cohesive powders. These materials, which can be called

glidants, are useful additives when good flow properties are required of a

powder.

Vibration

and tapping may maintain or improve the flow of cohesive powders by preventing

or destroying the bridges and arches responsible for irregular movement or

blockage. Vibration and tapping to initiate flow are less satisfactory because

the associated increase in bulk density due to closer packing renders the

powder more cohesive.