Pool Boiling

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Heat Transfer

If a horizontal heating surface is in contact with a boiling liquid, a sequence of events occurs as the temperature difference between the surface and the liquid increases.

POOL BOILING

If a horizontal

heating surface is in contact with a boiling liquid, a sequence of events

occurs as the temperature difference between the surface and the liquid

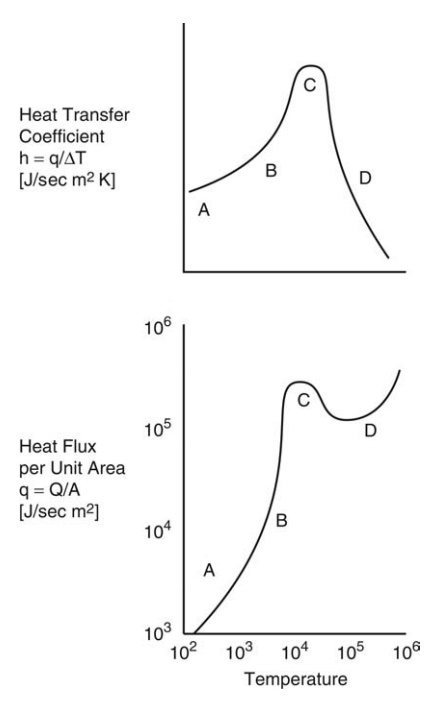

increases. Figure 3.3 relates heat flux per unit area at the surface, q, to the temperature difference between

the surface and boiling water, ΔT.

The derived value of the heat transfer coefficient, h = q/ΔT, is also plotted.

When

ΔT is small, the

degree of superheating of the liquid layers adjacent to the surface is low, and

bubble formation, growth, and disengagement, if present, are slow. Liquid

disturbance is small, and heat transfer can be estimated from expressions for

natural convection given, for example, in equation (3.11). This regime

corresponds to section AB of Figure 3.3, over which both q and h increase.

FIGURE 3.3 Variation in heat transfer coefficient and heat flux per unit area.

In

section BC of Figure 3.3, vapor formation becomes more vigorous and bubble

chains rise from points that progressively increase in number and finally

merge. This movement increases liquid circulation, and both q and h rise

rapidly. This phase is called nucleate boiling and is the practically important

regime. For water, approximate values of q

and h may be read from Figure 3.3. At

point C, a peak flux occurs and a maximum heat transfer coefficient is

obtained. ΔT at this point is

known as the critical temperature drop. For water, the value lies between 25

and 32 K. The critical temperature drop for organic liquids is somewhat higher.

Beyond C, vapor formation is so rapid that escape is inadequate and a progressively

larger fraction of the heating surface becomes covered with a vapor film, the

low conductivity of which leads to a decrease in q and h. This represents a

transition from nucleate boiling to film boiling. When this transition is

complete (D), the vapor entirely covers the surface, film boiling is fully

established, and the heat flux again rises.

The

low heat transfer coefficient renders film boiling undesirable, and equipment

is designed for and operated at temperature differences that are less than the

critical temperature drop. If a constant temperature heat source, such as steam

or hot liquid, is employed, exceeding the critical temperature drop results

simply in a drop in heat flux and process efficiency. If, however, a constant

heat input source is used, as in electrical heating, decreasing heat flux as

the tran-sition region is entered causes a sudden and possibly damaging

increase in the temperature of the heating element. Damage is known as boiling

burnout. Under these circumstances, the region CD of Figure 3.3 is not

obtained.

Boiling

heat transfer coefficients depend on both the physical character of the liquid

and the nature of the heating surface. Through the agencies of wet-ting,

roughness, and contamination, the latter greatly influences the formation,

growth, and disengagement of bubbles in the nucleate boiling regime. There is,

at present, no reliable method of estimating the boiling coefficients of heat

transfer from the physical properties of the system. Coefficients, as shown for

water in Figure 3.3, are large, and higher resistances elsewhere will often

limit the rate at which heat can be transferred through a system as a whole.

Related Topics