Sterility Testing: Pharmaceutical Products

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Sterility Testing: Pharmaceutical Products

A sterility test may be defined as - ‘a test that critically assesses whether a sterilized pharmaceutical product is free from contaminating microorganisms’.

STERILITY

TESTING : PHARMACEUTICAL PRODUCTS

INTRODUCTION

A sterility test may be defined as - ‘a test that critically assesses whether a

sterilized pharmaceutical product is free from contaminating microorganisms’.

According

to Indian Pharmacopoea (1996) the sterility testings are intended for

detecting the presence of viable forms of microorganisms in or on the

pharmacopoeal preparations.

In actual

practice, one invariably comes across certain absolutely important guidelines

and vital precautionary measures that must be adhered to strictly so as to

accomplish the utmost accuracy and precision of the entire concept of sterility

testing for life-saving secondary pharmaceutical products (drugs). A few such cardinal factors, guidelines, and necessary

details are as enumerated under :

(a) Sterility testing, due to

its inherent nature, is intimately associated with a statistical process

wherein the portion of a batch is sampled almost randomly* ; and, therefore,

the chance of the particular batch (lot) duly passed for actual usage

(consumption) solely depends upon the ‘sample’

having passed the stringent sterility test.

(b) Sterility tests should

be performed under conditions designed to avoid accidental contamination of the

product (under investigation) during the test. Nevertheless, such particular

precautions precisely taken for this purpose must not, in any case, adversely

affect any microbes that should be revealed in the test ultimately.

(c) Working

environment wherein the sterility tests

are meticulously carried out must be adequately monitored at regular intervals

by sampling the air and the surface of the working area by performing necessary

control tests.

(d) Sterility tests are

exclusively based upon the principle that in case the bacteria are

strategically placed in a specific medium that caters for the requisite

nutritive material and water, and maintained duly at a favourable temperature

(37 ± 2°C), the microbes have a

tendency to grow, and their legitimate presence may be clearly indicated by the

appearance of a turbidity in the

originally clear medium.

(e) Extent

of probability in the detection of viable microorganisms for the tests for sterility usually increases

with the actual number supposedly present in a given quantity of the

preparation under examination, and is found to vary according to the species of

microorganisms present. However, extremely low

levels of contamination cannot

be detected conveniently on the basis of random sampling of a batch.*

(f) In

case, observed contamination is not quite uniform throughout the batch, random

sampling cannot detect contamination with absolute certainty. Therefore, compliance with the tests for sterility

individually cannot certify absolute

assurane of freedom from microbial contamination. Nevertheless, greater assurance of sterility should

invariably originate from reliable stringent manufacturing procedures vis-a-vis strict compliance with Good

Manufacturing Practices (GMPs).

(g) Tests for sterility are

adequately designed to reveal the presence of microorganisms in the ‘samples’ used in the tests. However,

the interpretation of results is solely based upon the assumption that the contents of each and every

container in the batch, had they been tested actually, would have complied with the tests. As it is not practically possible to test every

container, a sufficient number of containers must be examined to give a suitable

degree of confidence in the ultimate results obtained of the tests.

(h) It

has been duly observed that there exists no

definite sampling plan for applying the tests to a specified proportion of

discrete units selected carefully from a batch is capable of demonstrating that almost all of the untested units are in fact sterile absolutely.

Therefore, it is indeed quite pertinent that while determining the number of units to be tested, the

manufacturer must have adequate regar to the environment parameters of

manufacture, the volume of preparation per container together with other

special considerations specific to the preparation under investigation. For

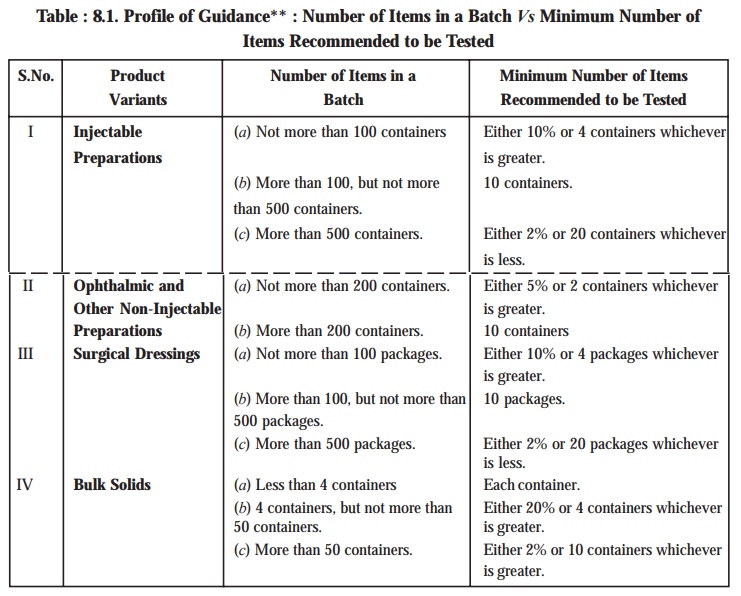

this Table 8.1 records the guidance on the exact number of items recommended to

be tested with regard to the number of items in the batch on the assumption

that the preparation has been duly manufactured under specified stringent

parameters designed meticulously to exclude any untoward contamination.

TEST FOR

STERILITY : PHARMACEUTICAL PRODUCTS

In a

broader perspective the wide-spectrum of the pharmaceutical products, both pure and dosage forms, may be

accomplished by adopting any one of the following two well-recognized, time-tested, and universally accepted methods,

namely :

(a) Membrane

Filtration, and

(b) Direct

Inoculation.

These two methods stated above shall now be

treated individually in the sections that follows :

Related Topics

![Microbial Variations [Genetic Manipulation in Microorganisms]](https://www.pharmacy180.com/media/article/small/empty.jpg)