Methods of Sterility Testing: Pharmaceutical Products

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Sterility Testing: Pharmaceutical Products

In a broader perspective the wide-spectrum of the pharmaceutical products, both pure and dosage forms, may be accomplished by adopting any one of the following two well-recognized, time-tested, and universally accepted methods, namely : (a) Membrane Filtration, and (b) Direct Inoculation.

TEST FOR

STERILITY : PHARMACEUTICAL PRODUCTS

In a

broader perspective the wide-spectrum of the pharmaceutical products, both pure and dosage forms, may be

accomplished by adopting any one of the following two well-recognized, time-tested, and universally accepted methods,

namely :

(a) Membrane

Filtration, and

(b) Direct

Inoculation.

These two methods stated above shall now be

treated individually in the sections that follows :

1. Membrane Filtration

The membrane filtration method has gained

and maintained its glorious traditional recognition to not only circumvent but

also to overcome the activity of

antibiotics for which there exist practically little inactivating agents. However, it may be duly extended to embrace

legitimately a host of other relevant products as and when deemed fit.

Importantly,

the method emphatically requires the following characteristic features, namely

:

·

an exceptional skill,

·

an in-depth specific knowledge, and

·

rigorous routine usage of positive and negative

controls.

As a

typical example of a suitable positive

control with respect to the appropriate usage of a known ‘contaminated solution’ essentially

comprising of a few microorganisms of altogether different nature and types*.

Salient Features : The salient features of the ‘membrane filtration’ method are as

enumerated under :

(1) The

solution of the product under investigation is carefully filtered via a hydrophobic-edged membrane

filter that would precisely retain any

possible contaminating microorganisms.

(2) The

resulting membrane is duly washed in situ

to get rid of any possible ‘traces of

antibiotic’ that would have been sticking to the surface of the membrane

intimately.

(3) Finally,

the segregated microorganisms are

meticulously transferred to the suitable

culture media under perfect

aseptic environment.

Microorganisms for Positive Control Tests : There

are, infact, four typical microorganisms that

are being used exclusively for the positive

control tests along with their respective type of specific enzymatic

activity mentioned in parentheses :

(a) Bacillus cerreus : [Broad

spectrum] ;

(b) Staphylococcus aureus :

[Penicillinase] ;

(c) Klebsiella aerogenes :

[Penicillinase + Cephalosporinase] ; and

(d) Enterobacter species :

[Cephalosporinase].

Interestingly,

the microorganisms invariably employed for the positive control tests together with a particular product

containing essentially an ‘antimicrobial

agent’ must be, as far as possible, explicitely

sensitive to that agent, in order that the ultimate growth of the microbe solely indicates three

vital and important informations, namely :

·

satisfactory inactivation,

·

satisfactory dilution,

and

·

satisfactory removal

of the agent.

Specific Instances of Pharmaceutical Products : Virtually

all the ‘Official Compendia’ viz., Indian Pharmacopoea (IP) ; British Pharmacopoea (BP), United States

Pharmacopoea (USP) ; European Pharmacopoea (Eur. P), and International Pharmacopoea (Int. P.) have

duly provided comprehensive and

specific details with regard to the ‘tests

for sterility’ of parenteral products

(e.g.., IV and IM injectables), ophthalmic preparations (e.g., eye-drops, eye-ointments,

eye-lotions etc.) ; besides a plethora of non-injectable

preparations, such as : catgut,

dusting powder, and surgical

dressings.

Test Procedures : In a

broader perspective, the membrane

filtration is to be preferred exclu-sively in such instances where the

substance under investigation could any one of the following four classes of pharmaceutical preparations :

(i) an oil or oil-based product,

(ii) an ointment that may be put into solution,

(iii) a non-bacteriostatic solid that does not

become soluble in the culture medium rapidly, and

(iv) a soluble powder or a liquid that essentially possesses

either inherent bacteriostatic or inherent fungistatic characteristic

features.

The membrane filtration must be used for

such products where the volume in a container is either 100 mL or more. One

may, however, select the exact number of samples

to be tested from Table 8.1 ; and subsequently use them for the respective culture

medium suitably selected for microorganisms

and the culture medium appropriately selected for fungi.

Precautionary Measures : In actual

practice, however, the tests for

sterility must always be carried

out under highly specific experimental parameters so as to avoid any least

possible accidental contamination of the product being

examined, such as :

(a) a

sophisticated laminar sterile airflow

cabinet (provided with effective hepa-filters),

(b) necessary

precautionary measures taken to be such so as to avoid contamination that they

do not affect any microbes which must be revealed duly in the test.

(c) ensuing

environment (i.e., working

conditions) of the laboratory where the ‘tests

for sterility’ is performed must always be monitored at a definite

periodical interval by :

·

sampling the air

of the working area,

·

sampling the surface

of the working area, and

·

perforing the stipulated control tests.

Methodology : In usual practice, it is

absolutely urgent and necessary to first clean meticulously the exterior surface of

ampoules, and closures of vials and

bottles with an appropriate antimicrobial

agent ; and thereafter, the actual

access to the contents should be gained carefully in a perfect aseptic manner.

However, in a situation where the

contents are duly packed in a particular container under vacuum, introduction

of ‘sterile air’ must be done by the

help of a suitable sterile device, for instance : a needle duly attached to a syringe barrel with a non-absorbent cotton.

Apparatus : The most suitable unit comprises

of a closed reservoir and a receptacle between which a properly supported membrane

of appropriate porosity is placed strategically.

·

A membrane usually found to be quite suitable for

sterility testing essentially bears a nominal

pore size not more than 0.45 μm, and diameter of nearly 47 mm, the

effectiveness of which in the

retention of microbes has been established adequately.

·

The entire unit is most preferably assembled and

sterilised with the membrane in place prior to use.

·

In case, the sample happens to be an oil, sterilize the membrane separately

and, after thorough drying, assemble the unit, adopting appropriate aseptic

precautionary measures.

Diluting of Fluids : In the ‘test for sterility’ one invariably

comes across with two

different types of fluids which

will be treated individually in the sections that follows :

(a) Fluid A—Digest 1 g of peptic digest of animal tissue* or its

equivalent in water to make up the volume upto 1L, filter or centrifuge to

clarify, adjust to pH 7.1 ± 0.2,

dispense into flasks in 100 mL quantities, and finally sterilize at 121° C for

20 minutes (in an ‘Autoclave’).

Note : In a specific instance, where Fluid A is to

be used in carrying out the tests for sterility on a specimen of the penicillin

or cephalosporin class of anibiotics, aseptically incorporate an amount of

sterile penicillinase to the Fluid A to be employed to rinse the membrane(s)

sufficient to inactivate any residual antibiotic activity on the membrane(s)

after the solution of the specimen has been duly filtered.

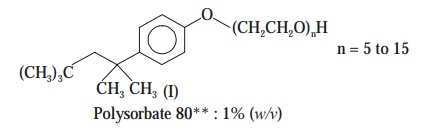

(b) Fluid B : In a specific instance, when the

test sample usually contains either oil

or lecithin*, use Fluid A to each litre of which has been

added 1 mL of Polysorbate 80**,

adjust to pH 7.1 ± 0.2, dispense into flasks and sterilize at 121° C for 20

minutes (in an ‘Autoclave’).

Note : A sterile fluid shall not have either

antimicrobial or antifungal properteis if it is to be considered suitable for

dissolving, diluting or rinsing a preparation being examined for sterility.

Quantum of Sample Used for ‘Tests for Sterility’ : In fact,

the exact and precise quantities of sample

to be used for determining the ‘Tests

for Sterility’ are quite different for the injectables and ophthalmics plus

other non-injectables ; and,

therefore, they would be discussed separately as under :

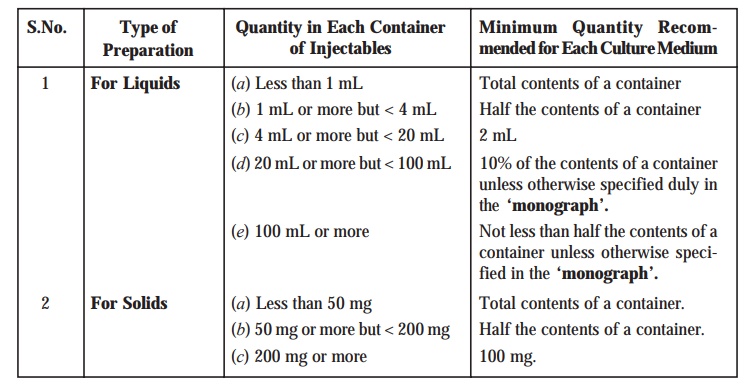

(a) For Injectable Preparations : As a

common routine practice and wherever possible always use the whole contents of

the container ; however, in any case not less than the quantities duly stated

in Table : 8.2, diluting wherever necessary to 100 mL with an appropriate sterile diluent e.g., Fluid A.

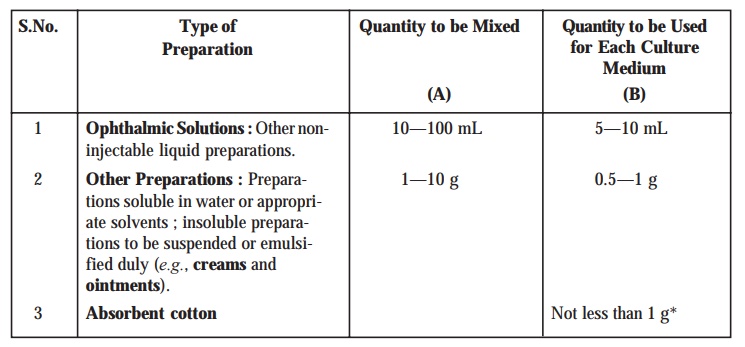

(b) For Ophthalmic and other Non-injectable

Preparations : In this particular instance exactly take an amount

lying very much within the range prescribed in Column (A) of Table : 8.3, if

necessary, making use of the contents of more than one container, and mix

thoroughly. For each specific medium use the amount duly specified in column

(B) of Table : 8.3. taken carefully from the mixed sample.

Table : 8.2. Quantities of Liquids/Solids per

Container of Injectables Vs Minimum

Quantitiy Recommended for Each Culture Medium.

Table : 8.3. Type of Preparation Vs Quantity to be Mixed and Quantity to

be Used for Each Culture Medium

Method of Actual Test : In

reality, the method of actual test may

be sub-divided into the following four categories, namely :

(i) Aqueous

Solutions,

(ii) Liquids

Immiscible with Aqueous Vehicles and Suspensions

(iii) Oils

and Oily Solutions, and

(iv) Ointments

and Creams.

These three aforesaid types of pharmaceutical

preparations shall be treated separately as under :

[I] Aqueous Solutions : The

following steps may be followed sequentially :

(1) Prepare

each membrane by transferring aseptically a small amount (i.e., just

sufficient to get the membrane moistened duly) of fluid A on to the membrane and filtering it carefully.

(2) For

each medium to be employed, transfer aseptically into two separate membrane filter funnels

or two separate sterile pooling

vessels prior to transfer not less than the quantity of the prepa-ration

being examined which is duly prescribed either in Table : 8.2 or Table : 8.3.

(3) Alternatively,

transfer aseptically the combined quantities of the preparation being examined

prescribed explicitely in the two

media onto one membrane exclusively.

(4) Suck

in the ‘liquid’ quickly via the membrane filter with the help of a negative pressure (i.e., under vacuum).

(5) In

case, the solution being examined has significant

antibacterial characteristic features, wash the membrane(s) by filtering

through it (them) not less than three

successive quantities, each of approximately 100 mL of the sterile fluid A.

(6) Precisely,

the quantities of fluid actually employed must be sufficient to permit the

adequate growth of a ‘small inoculum of

microorganisms’ (nearly 50) sensitive to the antimicrobial substance in the

presence of the residual inhibitory material retained duly on the membrane.

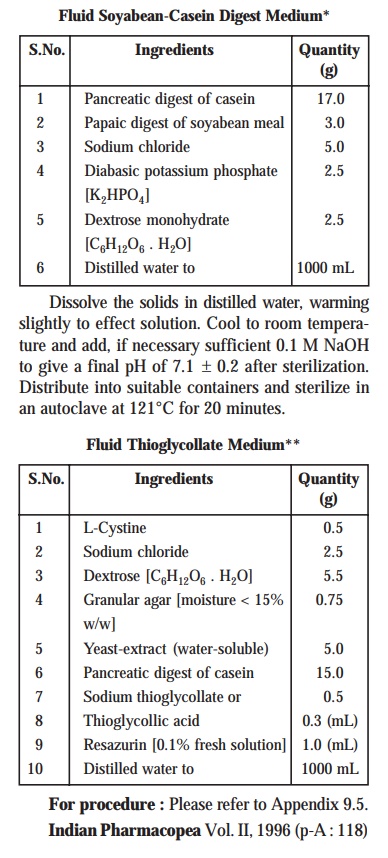

(7) Once

the filtration is completed, aseptically remove the membrane(s) from the

holder, cut the membrane in half, if only one is used, immerse the membrane or

1/2 of the membrane, in 100 mL of the ‘Fluid

Soyabean-Casein Digest Medium’*, and

incubate at 20–25°C for a duration of seven days.

(8) Likewise,

carefully immerse the other membrane, or other half of the membrane, in 100 mL

of ‘Fluid Thioglycollate Medium’,**

and incubate duly at 30–35° C for not

less than seven days.

[II] Liquids Immiscible with Aqueous Vehicles and

Suspensions : For this one may carry out the ‘test’ as

stipulated under [I] Aqueous Solutions,

but add a sufficient amount of fluid A

to the pooled sample to accomplish fast and rapid rate of filtration.

Special Features : These are

as stated under :

(1) Sterile enzyme preparations, for

instance :

Penicillinase

Cellulase

can be

incorporated to fluid A to help in

the dissolution of insoluble substances.

(2) In a

situation when the substance under test usually contains lecithin, alway make use of fluid

B for dilution.]

[III] Oils and Oily Solutions : The

various steps that are essentially involved in treating oils and oily solutions for carrying out the ‘test for sterility’ are as enumerated under :

(1) Filter

oils or oily solutions of

sufficiently low vicosity as such i.e., without any dilution via a dry membrane.

(2) It is

absolutely necessary to dilute viscous oils as necessary with an appropriate sterile diluent e.g., isopropyl myristate which

has been proved beyond any reasonable doubt not to exhibit any antimicrobial

activities under the prevailing parameters of the test.

(3) Permit

the ‘oil’ to penetrate the membrane,

and carry out the filtration by the application of gradual suction (with a

vaccum pump).

(4) Wash

the membrane by filtering through it at least 3/4 successive quantities, each

of nearly 100 mL of sterile fluid B

or any other appropriate sterile diluent.

(5) Complete

the test as described under [I] Aqueous

Solutions from step (7) onwards.

[IV] Ointments and Creams : The

various steps involved are as stated under :

(1) Dilute

ointments carefully either in a ‘fatty base’ or ‘emulsions’ of the water-in-oil

(i.e., w/o) type to yield a fluid concentration of approx. 1% w/v, by

applying gentle heat, if necessary, to

not more than 40°C with the aid of an appropriate sterile diluent e.g., isopropyl myristate previously adequately sterilized by filtration via a 0.22 μm

membrane filter which has been shown not to possess antimicrobial activities under the

prevailing conditions of the test.

(2) Carry

out the filtration as rapidly as possible as per details given under ‘Oils and Oily Solu-tions’ [Section

III] from step (4) onwards.

(3) However,

in certain exceptional instances, it would be absolutely necessary to heat the

substance to not more than 45°C, and

to make use of ‘warm solutions’ for

washing the membrane effectively.

Note : For ointments and oils that are almost

insoluble in isopropyl myristate one may employ the second method viz., ‘Direct Inoculation’ [Section 2.2].

[V] Soluble Soids : For each

individual cultrue medium, dissolve not less the quantity of the substance being examined, as

recommended in Tables : 8.2 and 8.3, in an appropriate sterile solvent e.g.,

fluid A, and perform the test described under Section (I) i.e., Aqueous Solutions, by employing a membrane suitable for

the selected solvents.

[VI] Sterile Devices : Pass

carefully and aseptically a sufficient volume of fluid B via each of not less than 20 devices so that not less than 100 mL is recovered

ultimately from each device. Collect the fluids in sterile containers, and

filter the entire volume collected via

membrane filter funnel(s) as

described under Section (I), Aqueous Solutions.

2. Direct Inoculation [or Direct Inoculation of Culture Media]

The three usual methods being used for

performing the ‘tests for sterility’

are as enumerated under :

(a) Nutrient

Broth,

(b) Cooked

Meat Medium and Thioglycollate Medium, and

(c) Sabouraud Medium.

These

methods shall now be treated individually in the sections that follows :

2.1. Nutrient Broth

Importantly,

it is exclusively suitable for the ‘aerobic

microorganisms’.

·

Oxidation-reduction potential (Eh) value

of this medium happens to be quite high to enable the growth of the anaerobes specifically.

·

Importantly, such culture media that particularly

allow the growth of festidious

microor-ganisms, such as : soyabean

casein digest broth, Hartley’s digest broth.*

2.2. Cooked Meat Medium and Thioglycollate Medium

These two different types of media are discussed

briefly as under :

(a) Cooked Meat Medium : It is

specifically suited for the cultivation (growth) of clostridia**.

(b) Thioglycollate Medium : It is

particularly suited for the growth of anaerobic

microbes. It essentially comprises of the following ingredients, namely :

Glucose and Sodium thioglycollate— that

invariably serve as :

·

an inactivator

of mercury compounds,

·

to augment and promote

reducing parameters, and

·

an oxidation-reduction

indicator.

Agar—to cause reduction of the

ensuing ‘convection currents’.

2.3. Sabouraud Medium

It is a

medium specifically meant for fungal

species. It essentially bears two

vital and important characteristic features, such as :

·

an acidic

medium, and

·

contains a rapidly

fermentable carbohydrate e.g.,

glucose or maltose.

Note : (1) All the three aforesaid media must be

previously assessed adequately for their nutritive characteristic features i.e., in fertility tests to ascertain

the growth of specified microorganisms.

(2) Duly incubated at the stipulated temperature(s).

The direct inoculation method shall now be

dealt with in a sequential manner under the following three categories, such as :

·

Quantities of sample to be employed,

·

Method of test, and

·

Observation and Interpretation of Results.

Quantities of Sample to be used : In actual

practice, the precise quantum of the

substance or pharmaceutical

preparation under investigation, that is required to be used for inoculation in the respective culture

media usually varies justifiably as per the amount present in each

particular con-tainer, and is stated clearly in Table : 8.2 together with the

exact volume of the culture medium to be employed.

Method of Test : The ‘method of test’ varies according to the substance to be examined,

for instance :

(a) Aqueous Solutions and Suspensions : The

actual tests for microbial contamination

are invariably performed on the

same sample of the preparation under investigation by making use of the

above-stated media (Section 2.2.1 through 2.2.3). In certain specific instance

when the amount present in a single container is quite insufficient to carry

out the stipulated ‘tests’, the

combined contents of either two or mroe containers may be employed to inoculate

the above-stated media.

Methodology : The various sequential steps involved

are as given under :

(1) Liquid

from the ‘test containers’ must be

removed carefully with a sterile pipette or with a sterile syringe or a needle.

(2) Transfer

aseptically the requistite prescribed volume of the substance from each

container to a vessel of the culture medium.

(3) Mix

the liquid with the medium carefully taking care not to aerate excessively.

(4) Incubate

the ‘inoculated media’ for not less

than 14 days (unless otherwise specifically mentioned in the monograph*) at : 30–35°C for ‘Fluid Thioglycollate Medium’, and

20–25°C for ‘Soyabean-Casein Digest

Medium’.

Special Points : The following special points may be noted meticulously :

(i) In

case, the substance under investigation renders the culture medium turbid whereby the presence or absence

of the actual microbial growth may

not be determined conveniently and readily by sheer ‘visual examination’, it is always advisable and recommended that a

suitable transfer of a certain portion of the medium to other fresh vessels of

the same medium between the 3rd and

7th days after the said test actually commenced.

(ii) Subsequently,

continue the incubation of the said ‘transfer

vessels’ for not less than 7

addi-tional days after the transfer, and for a total of not less than 14 days.

(b) Oils and Oily Solutions : For

carrying out the required tests for the bacterial contamination of oils and oily solutions it is recommended to make use of culture media to which have been

incorpo-rated duly :

Octylphenoxy

polyethoxyethanol (I) : 0.1% (w/v) [or Octoxynol]

However,

these emulsifying agents should not exhibit any inherent antimicrobial

characteristic features under the prevailing parameters of the ‘test’.

The

required test must be carried out as already described under Section (a) above i.e., Aqueous Solutions and Suspensions.

Precautionary Measures : The

following two precautionary measures should

be taken adequately :

(i) Cultures essentially comprising of ‘oily preparations’ should be shaken

gently every day.

(ii) Importantly,

when one employs the fluid

thioglycollate medium for the ultimate detection of the anaerobic microorganisms, shaking or

mixing must be restricted to a bear minimum level so as to maintain perfect anaerobic experimental parameters.

(c) Ointments : The following steps may be

adopted in a sequential manner :

(1) Carefully

prepare the ‘test sample’ by

diluting ten times in a sterile diluent, for instance : Fluid B or any other suitable aqueous vehicle which is capable of

dispersing the test material homogene-ously throughout the ‘fluid mixture’.*

(2) Mix

10 mL of the fluid mixture thus

obtained with 80 mL of the medium, and subsequently proceed as per the method

given under Section (a) i.e., Aqueous Solutions and Suspensions.

(d) Solids : The various steps involved are as

stated under :

(1) Transfer

carefully the requisite amount of the preparation under examination to the

quantity of culture medium as specified in Table : 8.3, and mix thoroughly.

(2) Incubate

the inoculated media for not less than 14 days, unless otherwise mentioned in

the monograph at 30–35°C in the particular instance of fluid thioglycollate medium, and at 20–25°C in the specific case of

soyabean-casein digest medium.

(e) Sterile Devices : For

articles of such size and shape as allow the complete immersion

in not more than 1 L of the culture

medium test the intact article, using the suitable media ; and incubating as

stated under Section (a) i.e., Aqueous Solutions and Suspensions.

(f) Transfusion or Infusion Assemblies : For transfusion or infusion assemblies or

where the size of an item almost

renders immersion impracticable, and exclusively the ‘liquid pathway’ should be sterile by all means, flush carefully

the lumen of each of twenty units

with a sufficient quantum of fluid thioglycollate medium and the lumen of

each of 20 units with a sufficient

quantum of soyabean-casein digest medium

to give an ultimate recovery of not less than 15 mL of each medium.

Finally, incubate with not less than

100 mL of each of the two media as prescribed under Section (a) i.e.,

Aque-ous Solutions and Suspensions.

Exception : Such ‘medical devices’ wherein the lumen is so small such that fluid thioglycollate medium will not

pass through easily, appropriately substitute alternative thioglycollate medium instead of the usual fluid thioglycollate medium and incubate

that duly inoculated medium

anaerobically.

Note : In such situations where the presence of the

specimen under examination, in the culture medium critically interferes with

the test by virtue of the ensuing bacteriostatic or fungistatic action, rinse

the article thoroughly with the bare minimum quantum of fluid A. Finally recover the rinsed fluid and carry out the ‘test’

as stated under ‘Membrane Filtration’ for Sterile Devices.

Observation and Interpretation of Results : In the

case of ‘direct inoculation’ the

various observation and interpretation

of results may be accomplished by taking into consideration the fol-lowing cardinal factors, such as :

(1) Both

at intervals during the incubation

period, and at its completion,

the media may be examined thoroughly for the critical macroscopic evidence of the bacterial growth.

(2) In

the event of a negative evidence,

the ‘sample’ under examination

passes the ‘tests for sterility’.

(3) If positive

evidence of microbial growth is found, reserve the containers exhibiting this,

and unless it is amply proved and adequately demonstrated by any other means

that their (microorganisms) presence is on account such causes unrelated to the

‘sample’ being examined ; and,

therefore, the tests for sterility are pronounced invalid. In such cases, it may be

recommended to carry out a ‘retest’ employing

an identical number of samples and

volumes to be tested, and the media as in the original test.

(4) Even then,

if no evidence of microbial growth

is duly observed, the ‘sample’ under

inves-tigation precisely passes the ‘tests for sterility’.

(5) In

case, reasonable evidence of bacterial growth is observed, one may go ahead

with the isolation and subsequent identification of the organisms.

(6) If

they are found to be not readily distinguishable from those (microbes) growing

in the containers reserved in the very First

Test, the ‘sample’ under

investigation fails the ‘tests for sterility’.

(7) In

case, the microorganisms are readily distinguishable from the ones actually

growing in the containers reserved in the ‘First

Test’, it is very much advisable to carry out a ‘Second Retest’ by employing virtually twice the number of samples.

(8) Importantly,

if no evidence of bacterial growth

is observed in the ‘Second Retest’,

the sample under examination legitimately passes

the ‘tests for sterility’.

(9) Contrarily,

if evidence of growth of any

microorganisms is duly observed in the ‘second

retest’, the sample under investigation obviously fails the ‘tests for sterility’.

Related Topics