Sensitivity of Microorganisms

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Sterilization Procedures And Sterility Assurance

The general pattern of resistance of microorganisms to biocidal sterilization processes is independent of the type of agent employed (heat, radiation or gas), with vegetative forms of bacteria and fungi, along with the larger viruses, showing a greater sensitivity to sterilization processes than small viruses and bacterial or fungal spores.

SENSITIVITY OF MICROORGANISMS

The general pattern of resistance of

microorganisms to biocidal sterilization processes is independent of the type

of agent employed (heat, radiation or gas), with vegetative forms of bacteria

and fungi, along with the larger viruses, showing a greater sensitivity to

sterilization processes than small viruses and bacterial or fungal spores. The

choice of suitable reference organisms for testing the efficiency of

sterilization processes is therefore made from the most durable bacterial

spores; these are usually represented by Bacillus stearothermophilus for

moist heat, certain strains of B.subtilis for

dry heat and gaseous sterilization, and B.pumilus for

ionizing radiation.

Ideally, when considering the level of treatment necessary to achieve

sterility a knowledge of the type and total number of microorganisms present in

a product, together with their likely response to the proposed treatment, is

necessary. Without this information, however, it is usually assumed that

organisms within the load are no more resistant than the reference spores or

than specific resistant product isolates. In the latter case, it must be

remembered that resistance may be altered or lost entirely by repeated laboratory

subculture and the resistance characteristics of the maintained strain must be

regularly checked.

A sterilization process may thus be developed without a full microbiological

background to the product, instead being based on the ability to deal with a ‘worst

case’ condition. This is indeed the situation for official sterilization

methods, which must be capable of general application, and modern

pharmacopoeial recommendations are derived from a careful analysis of

experimental data on bacterial spore survival following treatments with heat,

ionizing radiation or gas.

However, the infectious agents responsible for spongiform

encephalopathies (prions) such as bovine spongiform encephalopathy (BSE) and

Creutzfeldt –Jakob disease (CJD) exhibit exceptional degrees of resistance to

many lethal agents. Recent work has even cast doubt on the adequacy of the

process of 18 minute exposure to steam at 134–138°C which has been recommended

for the destruction of prions (and which far exceeds the lethal treatment

required to achieve adequate destruction of bacterial spores).

a)

Survivor Curves

When exposed to a killing process,

populations of micro-organisms generally lose their viability in an exponential

fashion, independent of the initial number of organisms. This can be

represented graphically with a ‘survivor curve’ drawn from a plot of the

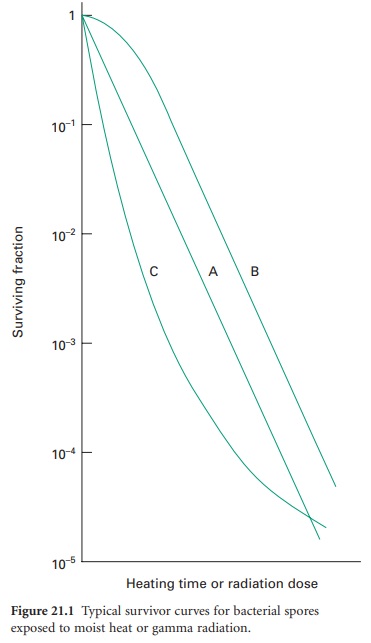

logarithm of the fraction of survivors against the exposure time or dose (Figure 21.1).

Of the typical curves obtained, all have a linear portion which may be

continuous (plot A), or may be modified by an initial shoulder (B) or by a

reduced rate of kill at low survivor levels (C). Furthermore, a short

activation phase, representing an initial increase in viable count, may be seen

during the heat treatment of certain bacterial spores. Survivor curves have

been employed principally in the examination of heat sterilization methods, but

can equally well be applied to any biocidal process.

b)

Expressions Of Resistance

i) D-value

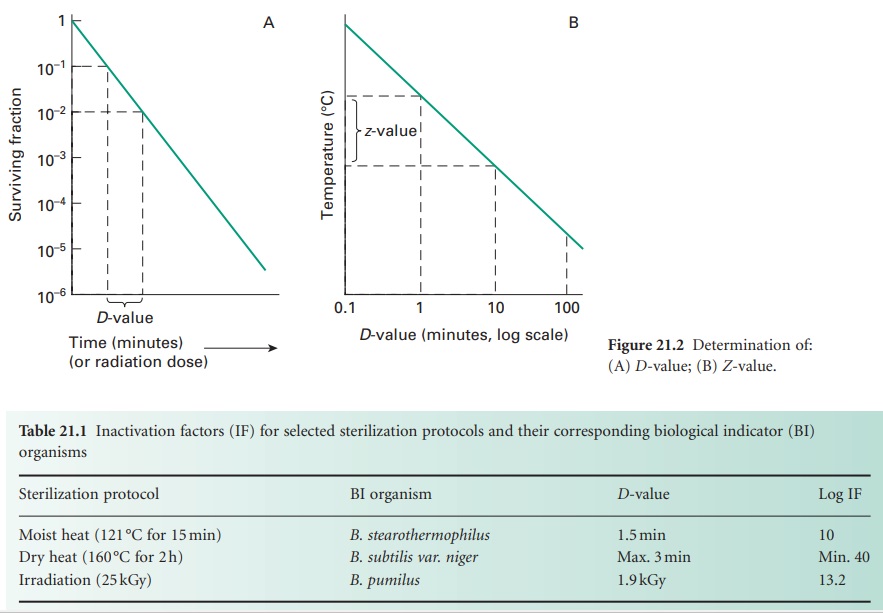

The resistance of an organism to a

sterilizing agent can be described by means of the D-value. For heat and radiation treatments, respectively,

this is defined as the time taken at a fixed temperature or the radiation dose

required to achieve a 90% reduction in viable cells (i.e. a 1 log cycle

reduction in survivors; Figure 21.2A).

The calculation of the D-value assumes a

linear type A survivor curve (Figure 21.1),

and must be corrected to allow for any deviation from linearity with type B or

C curves. Some typical D-values for

resistant bacterial spores are given in Table 21.1.

ii) Z-value

For heat treatment, a D-value only refers to the resistance of a

microorganism at a particular temperature. In order to assess the influence of

temperature changes on thermal resistance, a relationship between temperature

and log D-value can be developed, leading to the expression of

a Z-value, which represents the increase in temperature

needed to reduce the D-value of an

organism by 90% (i.e. 1 log cycle reduction; Figure 21.2 B).

For bacterial spores used as biological indicators for moist heat (B. stearothermophilus) and dry heat (B. subtilis) sterilization processes, mean Z-values are given as 10 °C and 22 °C, respectively.

The Z-value is not truly independent of temperature but may

be considered essentially constant over the temperature ranges used in heat

sterilization processes.

c)

Sterility Assurance

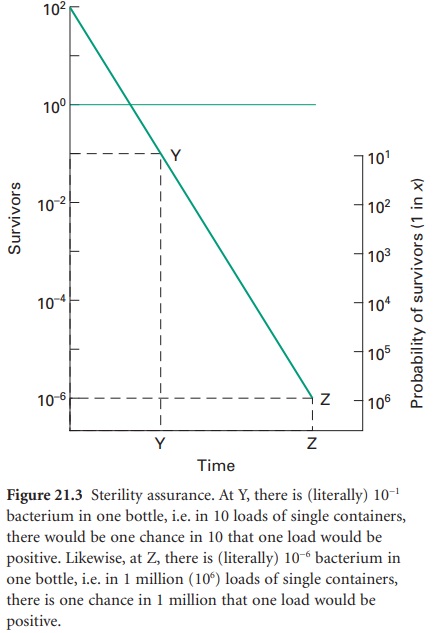

The term ‘sterile’, in a microbiological context, means no surviving organisms whatsoever. Thus, there are no degrees of sterility; an item is either sterile or it is not, and so there are no levels of contamination which may be considered negligible or insignificant and therefore acceptable. From the survivor curves presented, it can be seen that the elimination of viable microorganisms from a product is a time-dependent process, and will be influenced by the rate and duration of biocidal action and the initial microbial contamination level. It is also evident from Figure 21.2 A that true sterility, represented by zero survivors, can only be achieved after an infinite exposure period or radiation dose. Clearly, then, it is illogical to claim, or expect, that a sterilization procedure will guarantee sterility. Thus, the likelihood of a product being produced free of microorganisms is best expressed in terms of the probability of an organism surviving the treatment process, a possibility not entertained in the absolute term ‘sterile’. From this approach has arisen the concept of sterility assurance or a microbial safety index which gives a numerical value to the probability of a single surviving organism remaining to contaminate a processed product. For pharmaceutical products, the most frequently applied standard is that the probability, post-sterilization, of a non-sterile unit is no more than 1 in 1 million units processed (i.e. ≤ 10− 6).The sterilization protocol necessary to achieve this with any given organism of known D-value can be established from the inactivation factor (IF) which may be defined as:

IF =10t̷D

where t is the contact time (for a heat or gaseous sterilization process) or dose (for ionizing radiation) and D is the D-value appropriate to the process employed.

Thus, for an initial burden of 102 spores an inactivation factor of 108 will be needed to give the required sterility

assurance of 10−6 (Figure 21.3).

The sterilization process will therefore need to produce sufficient lethality

to achieve an 8 log cycle reduction in viable organisms; this will require

exposure of the product to eight times the D-value of the

reference organism (8 D). In practice, it

is generally assumed that the contaminant will have the same resistance as the

relevant biological indicator spores unless full microbiological data are available

to indicate otherwise. The inactivation factors associated with certain

sterilization protocols and their biological indicator organisms are given

in Table 21.1.

Related Topics