Binary Mixtures of Miscible Liquids

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Evaporation and Distillation

When the two components of a binary mixture are completely miscible, the vapor pressure of a mixture is a function of mixture composition as well as the vapor pressures of the two pure components.

Binary Mixtures of Miscible

Liquids

The Relation of Vapor Pressure

and Mixture Composition

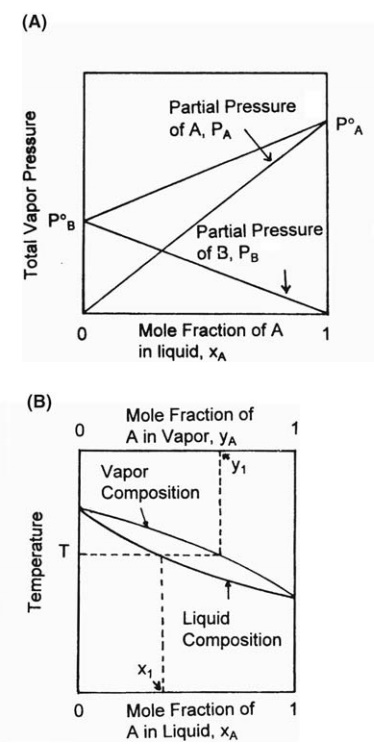

When the two components of a binary mixture are completely miscible, the vapor pressure of a mixture is a function of mixture composition as well as the vapor pressures of the two pure components. If the liquids are ideal, the relation of vapor pressure and composition is given by Raoult’s law. At a constant temperature, the partial vapor pressure of a constituent of an ideal mixture is proportional to its mole fraction in the liquid. Thus, for a mixture of A and B,

PA

= PAo

XA (10:7)

where

PA is the partial vapor pressure of A in the mixture, PAo

is the vapor pressure of pure A, and xA is its mole fraction.

Similarly,

PB

= PBoXB

(10:8)

The

total pressure of the system, P, is simply PA + PB.

These

relations can be expressed graphically. If the vapor pressure at a given

temperature of each pure component is marked on a graph of vapor pressure

versus mole fraction, the total vapor pressure at the same temperature of a

liquid mixture of any composition falls on the straight line joining the vapor

pressures of the two components. The partial pressure of each component is

indicated by the diagonals of this figure. The principle is shown in Figure

10.4. A separate relation must be constructed for each temperature.

Very

few liquid mixtures rigidly obey Raoult’s law. Consequently, the vapor pressure

data must be determined experimentally. Mixtures that deviate positively from

the law give a total vapor pressure curve that lies above the theoretical

straight line. Negative deviations fall below the line. In extreme cases,

deviations are so large that a range of mixtures will exhibit a higher or lower

vapor pressure than that of either of the pure components.

Returning

to ideal systems, the partial pressure of a component in the vapor is

proportional to its mole fraction. For component A,

PA

= yAP (10:9)

where

PA is the partial pressure of A in the vapor and yA is

its mole fraction.

FIGURE 10.4 (A) The vapor pressure of an

ideal binary mixture. (B) Phase diagram.

If

A is the more volatile component, PAo is greater than P ·

yA is therefore greater than xA, that is, the vapor is

richer in the more volatile component than the liquid with which it is in

equilibrium.

The Relation of Boiling Point

and Mixture Composition

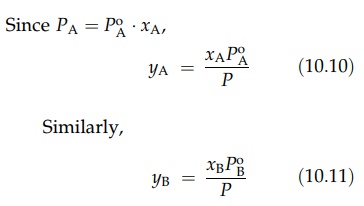

For

the purposes of distillation, curves relating vapor pressure and composition

are usually replaced by boiling point curves. These are determined by

experi-ment at the given pressure. Figure 10.5A represents a system in which

the vapor pressure of some mixtures is greater than the vapor pressure of the

pure, more volatile component. This system will exhibit a minimum boiling

point, and the composition of the liquid at this point is given by Z. This

mixture, which is a constant-boiling or azeotropic mixture, evolves on boiling

a vapor of the same composition. In the binary system described in Figure

10.5B, mixtures are formed with a vapor pressure that is less than that of the

less volatile compo-nent. The maximum boiling point is given by the azeotropic

mixture, Z.

Systems

that form minimum-boiling mixtures are common. Ethyl alcohol and water provide

an example, the azeotrope containing 4.5% by weight of water. The boiling point

at atmospheric pressure is 351.15 K, 0.25 K lower than the boiling point of

pure alcohol. Maximum-boiling mixtures are less common. The most familiar example

is hydrochloric acid, which forms an azeotrope boiling at 381 K and contains

20.2% by weight of hydrochloric acid.

Mixtures

that form azeotropes cannot be separated into the pure compo-nents by normal

distillation methods. However, separation into the azeotrope and one pure

component is possible. Efficient fractionation of the mixture M of Figure 10.5A

would give the azeotrope Z as distillate and pure B as the residue.

FIGURE 10.5 Temperature-composition diagrams

for a binary mixture. (A) Minimum azeotrope and (B) maximum azeotrope.

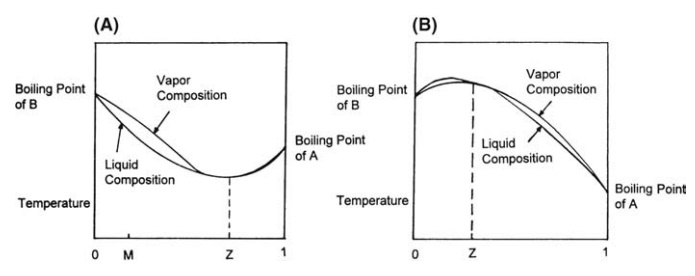

FIGURE 10.6 Vapor-liquid equilibrium diagrams.

The

composition of the azeotropic mixture of a system is a function of the total

pressure, and it is possible, in some cases, to eliminate the constant-boiling

mixture by altering the pressure at which the distillation is performed. For

example, at pressures less than 100 mmHg, ethyl alcohol and water do not form

an azeotrope. At this pressure, they can be completely separated.

Vapor-Liquid Equilibrium

Diagrams

Vapor-liquid

equilibrium diagrams of the form shown in Figure 10.6 provide an alternative

and convenient method of recording distillation data. They consist of a

conventional graph relating the mole fraction of the more volatile component in

the liquid, designated X, to the mole fraction of the more volatile component

in the vapor, designated Y. An ideal binary system is shown in Figure 10.6A.

The temperature varies along each of the curves, and the diagram is only

applicable to the pressure at which the variables were measured. Curves of

min-imum-boiling mixtures and maximum-boiling mixtures are drawn in Figure

10.6B and C, respectively.

Simple or Differential Distillation

In

simple or differential distillation, the vapor evolved from the boiling mixture

is immediately removed and condensed. For the system shown in Figure 10.7A, the

liquid of composition x1 evolves a vapor of composition y1.

Its removal impoverishes the liquid in the more volatile component. The

composition of the liquid moves toward pure B, and its boiling point increases.

There is, therefore, a progressive change in the composition of the vapor, the

mole fraction of the more volatile component steadily decreasing. Unless the

boiling points of the two pure components differ widely, a reasonable degree of

separation is not possible. The method may be used to remove low–boiling point

solvents from aqueous solutions.

Related Topics