Binary Mixtures of Immiscible Liquids: Steam Distillation

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Evaporation and Distillation

Distillation is a process in which a liquid mixture is separated into its component parts by vaporization.

DISTILLATION

Distillation

is a process in which a liquid mixture is separated into its component parts

by vaporization. The vapor evolved from a boiling liquid mixture is normally

richer in the more volatile components than the liquid with which it is in

equilibrium. Distillation rests on this fact. Although multicomponent mix-tures

are most common in distillation processes, an understanding of the operation

can be based on the vapor pressure characteristics of two-component or binary

mixtures. Binary systems in which the liquids are immiscible are discussed

first. Discussion of the separation of miscible liquids by fractionation forms

most of the remainder of the section.

Binary Mixtures of Immiscible Liquids: Steam Distillation

If

the two components of a binary mixture are immiscible, the vapor pressure of

the mixture is the sum of the vapor pressures of the two components, each

exerted independently and not as a function of their relative concentrations in

the liquid. This property is employed in steam distillation, a process

particularly applicable to the separation of high–boiling point substances from

nonvolatile impurities. The steam forms a cheap and inert carrier. The

principles of the process, however, apply to other immiscible systems.

If

a mixture of water and a high–boiling point liquid, such as nitrobenzene, is

heated, the total vapor pressure increases and ultimately reaches the external

pressure. The mixture boils, and the vapors evolved are condensed to give a

liquid mixture, which separates under gravity. In practice, the vapors are

pro-duced by blowing steam into the liquid in a manner that gives intimate

contact between the phases. Since both components contribute to the total

pressure, the boiling temperature must be lower than the boiling point of

either component. In the case of nitrobenzene and water, the boiling point at

atmospheric pressure is about 372 K. To distill nitrobenzene alone at this

temperature, a pressure of 20 mmHg must be imposed. Steam distillation,

therefore, permits the distillation of water-immiscible materials of high

boiling point without the use of high temperatures, which might cause

decomposition, or high vacua. The method, however, will only separate such

materials from nonvolatile constituents. If volatile impurities are present,

these will appear in the distillate.

The

composition of the distillate is calculated in the following way. For two

components, A and B, the total vapor pressure, P, is the sum of the vapor

pressures of the components, PA and PB. Since the partial

pressure of a com-ponent in a gaseous mixture is proportional to its molar

concentration, the composition of the vapor is given by

where

nA and nB are the number of moles of A and B in the

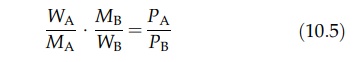

vapor, respectively. If WA and WB are the weights of A

and B in the vapor, then

where MA and MB are the respective molecular weights. The distillate obtained from the vapor is WA + WB. Therefore,

Percentage

of A in the distillate = WA / (WA + WB) x 100 = PAMA / (PAMA + PBMB) x 100 (10:6)

The

ratio of immiscible organic liquid to water in the distillate is increased if

the former has a high molecular weight or a high vapor pressure.

Steam

distillation under vacuum may be employed when the thermal stability of the

material prohibits temperatures of about 373 K. A further variant is the

introduction of unsaturated steam under conditions in which no con-densation to

water takes place. Only two phases, the liquid being distilled and the mixed

vapors, are then present. The external pressure no longer fixes the

temperature, as in a three-phase system, and any convenient value can be

chosen.

The

chief uses of steam distillation are the purification and isolation of liquids

of high boiling point, such as aniline, nitrobenzene, or s-dichlorobenzene, and the

preparation of fatty acids and volatile oils. Many of the latter are pre-pared

by introducing steam into a mixture of the comminuted drug and water. The

method is also used to remove odoriferous elements, such as aldehydes and

ketones, from edible oils. The dehydration of a material by adding a volatile,

water-immiscible solvent, such as toluene, and distilling the mixture is a form

of steam distillation. The solvent separates in the condensate and may be

returned to the still.

Related Topics