Crystallizers

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Crystallization

Although other methods may be adopted, crystallizers can be conveniently classified by the way in which a solution is supersaturated.

CRYSTALLIZERS

Although

other methods may be adopted, crystallizers can be conveniently classified by

the way in which a solution is supersaturated. This leads to the

self-explanatory terms: cooling crystallizer and evaporative crystallizer. In

vacuum crystallizers, both evaporation and cooling are used.

Cooling Crystallizers

Open

or closed tanks, agitated by stirrers, are used for batch crystallization. The

specific heat of the solution and the heat of crystallization are removed by

means of jackets or coils through which cooling water can be circulated.

Agitation destroys temperature gradients in the tanks, opposes sedimentation

and the irregular growth of crystals at the bottom of the vessel, and, as

described above, facilitates growth. Similar equipment is used for

crystallization or precipitation by the addition of a third substance.

Crystallizers

for continuous processes often take the form of a trough cooled naturally or by

a jacket. The solution enters at one end, and crystals and liquid are

discharged at the other. In one type of crystallizer, a slow-moving worm works

in the solution and lifts crystals off the cooling surface to shower them

through the solution and slowly convey them through the trough. The trough of

another is agitated by rocking. Baffles are used to increase the resi-dence

time of the solution. Both crystallizers are characterized by low heat transfer

coefficients, and an alternative arrangement consists essentially of a

double-pipe heat exchanger. The crystallizing fluid is carried in the central

pipe with countercurrent flow of the coolant in the annulus between the pipes.

A shaft rotates in the central tube carrying blades, which scrape the heat

transfer surface. High heat transfer coefficients are obtained. An Oslo

crystallizer, in which supersaturation is given by cooling, is described in

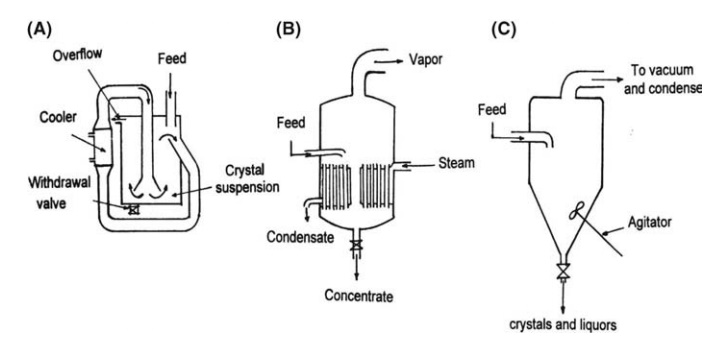

Figure 9.6A. The principles underlying this plant have already been described.

Evaporative Crystallizers

On

a small scale, simple pans and stirred reaction vessels can be used for

evaporative crystallization. Larger units may employ calandria heating, as

shown in Figure 9.6B. The downcomer, which must be large enough to accommodate

the flow of the suspension, commonly houses an impeller, forced circulation

increasing the heat transfer to the boiling/liquid. These units may be adapted

for either batch or continuous processes in which crystal size is not of great

importance. For continuous processes demanding close control of product size,

an Oslo crystallizer, which saturates the solution by evaporation, may be

employed.

FIGURE 9.6 (A) Cooling crystallizer, (B)

evaporative crystallizer, and (C) batch vacuum crys-tallizer.

Vacuum Crystallizers

Vacuum

crystallizers produce supersaturated conditions by solvent removal and cooling.

An example is shown in Figure 9.6C. A hot, concentrated solution is fed to an agitated

crystallization chamber maintained at low pressure. The solution boils and

cools adiabatically to the boiling point corresponding to the operating

pressure. Crystallization follows concentration, and the product is removed

from the bottom of the vessel. The principles of the Oslo crystallizers are

also employed in vacuum crystallization.

Related Topics