Crystallization from Solutions

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Crystallization

When a material crystallizes from a solution, nucleation and crystal growth occur simultaneously over a wide intermediate temperature range so that a study of these processes is more difficult.

CRYSTALLIZATION FROM SOLUTIONS

When a material

crystallizes from a solution, nucleation and crystal growth occur

simultaneously over a wide intermediate temperature range so that a study of

these processes is more difficult. In general, however, they are thought to be

similar to nucleation and crystal growth in melts. The three basic steps,

induction of supersaturation, formation of nuclei, and growth of crystals, are

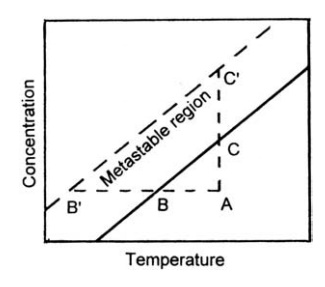

explained with reference to the solubility curve shown in Figure 9.2.

A

solution with temperature and concentration indicated by point A may be

saturated by either cooling to point B or removing solvent (point C). With

FIGURE 9.2 The solubility-supersolubility

diagram.

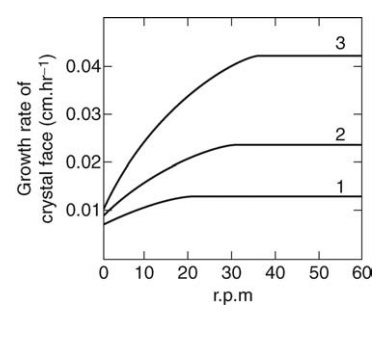

FIGURE 9.3 The effect of agitation on the rate of growth of a crystal of sodium thiosulfate.

If the degree

of supersaturation is small, the spontaneous formation of crystal nuclei is

highly improbable. Crystal growth, however, can occur if seeds are added. With

greater supersaturation, spontaneous nucleation becomes more probable and the

metastable region will be limited approximately by the line B’ C’ . If the solution

is cooled to B’

or concentrated by solvent removal to C’ , spontaneous nucleation is

virtually certain. Crystal growth will also occur in these conditions. The rate

of growth, however, is depressed at low temperatures.

During crystal

growth, deposition on the faces of the crystal causes depletion of molecules in

the immediate vicinity. The driving force is provided by the concentration

gradient setup, from supersaturation in the solution to lower concentrations at

the crystal face. A large degree of supersaturation, therefore, promotes a high

growth rate. A reaction at the surface, in which solute molecules become

correctly orientated in the crystal lattice, provides a second resistance to

the growth of the crystal. Simultaneously, the heat of crystallization must be

conducted away.

Agitation modifies

the rate of crystal growth for given conditions of temperature and saturation.

Initially, agitation quickly increases the rate of growth by decreasing the

thickness of the boundary layer and the diffusional resistance. However, as

agitation is intensified, a limiting value is reached, which is determined by

the kinetics of the surface reaction. In Figure 9.3, the effect of agitation on

the rate of crystal growth in solutions of sodium thiosulfate of differing

degrees of supersaturation is described.

As with melts,

soluble impurities may increase or retard the rate of nucleation. Insoluble

materials may act as nuclei and promote crystallization. Impurities may also

affect crystal form and, in some cases, are deliberately added to secure a

product with good appearance, absence of caking, or suitable flow properties.

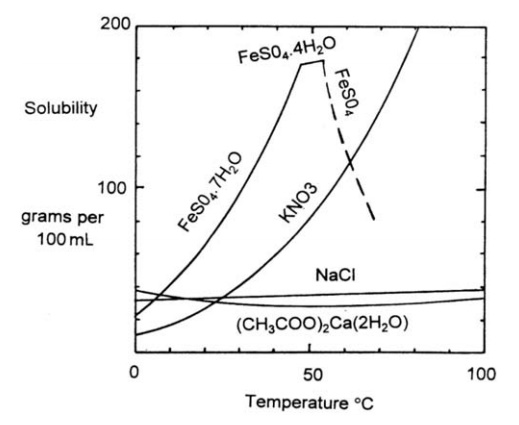

The temperature at

which crystallization is performed may be determined by the crystal form or

degree of hydration required of the products. Reference to the solubility

curves given in Figure 9.4 shows that crystallization at 50○C yields FeSO4

· 7H2O, at 60○C

yields FeSO4N · 4H2O, and at 70○C, FeSO4.

The majority of materials, however, have one or possibly two forms. The degree

of super-saturation of solution 1 is 5 g/L, of solution 2 is 10 g/L, and of

solution 3 is 15 g/L.

FIGURE 9.4 Solubility curves.

Related Topics