Production of Large Crystals

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Crystallization

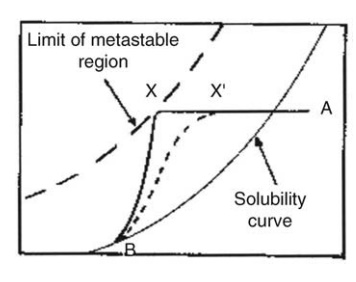

Batch production of large, uniform crystals may be carried out in agitated reaction vessels by slow, controlled or natural cooling. Spontaneous nucleation is improbable until solution A is cooled to X.

PRODUCTION OF LARGE CRYSTALS

Batch

production of large, uniform crystals may be carried out in agitated reaction

vessels by slow, controlled or natural cooling. Spontaneous nucleation is

improbable until solution A is cooled to X. Crystallization then follows the

path XB. Better control is gained if the solution is artificially seeded.

Seeding is shown at X’

. Crystallization then follows the broken line X’ B, the aim being to

maintain the solution in the metastable region where growth rate is high and

natural nucleation is low. The course of the crystallization is shown in Figure

9.5. Initially, spontaneous nucleation may be allowed by cooling from A to X.

As crystallization takes place, the degree of supersaturation and the

concentration of the solute fall, ultimately reaching saturation at B when

growth will cease. Closer control is secured by artificially seeding the

supersaturated solution in

FIGURE 9.5 The production of large

crystals. The conditions of supersaturation.

An

important principle for the continuous production of large even crystals is

used in Oslo or Krystal crystallizers. A metastable, supersaturated solution is

released into the bottom of a mass of growing crystals on which the solute is

deposited. The crystals are fluidized by the circulation of the solution, and

classification in this zone allows the withdrawal of sufficiently large

crystals from the bottom.

Related Topics