Bioavailability Enhancement Through Enhancement of Drug Solubility or Dissolution Rate

| Home | | Biopharmaceutics and Pharmacokinetics |Chapter: Biopharmaceutics and Pharmacokinetics : Bioavailability and Bioequivalence

Bioavailability Enhancement Through Enhancement of Drug Solubility or Dissolution Rate

BIOAVAILABILITY ENHANCEMENT THROUGH ENHANCEMENT OF DRUG SOLUBILITY OR

DISSOLUTION RATE

There are several ways by which drug solubility or

the dissolution rate can be enhanced.

Some of the widely used methods are discussed

briefly.

1. Micronization: The process involves reducing the

size of the solid drug particles to

1 to 10 microns commonly by spray drying or by use of air attrition methods

(fluid energy or jet mill). The process is also called as micro-milling. Examples

of drugs whose bioavailability have been increased by micronization include

griseofulvin and several steroidal and sulpha drugs.

2. Nanonisation: It‘s a process whereby the drug

powder is converted to nanocrystals

of sizes 200 - 600 nm, e.g. amphotericin B. The main production technologies

currently in use to produce drug nanocrystals yield as a product a dispersion

of drug nanocrystals in a liquid, typically water (called nanosuspension). There

are three basic technologies currently in use to prepare nanoparticles:

i. Pearl milling

ii. Homogenisation in water (wet

milling as in a colloid mill)

iii. Homogenisation in non-aqueous

media or in water with water-miscible liquids.

3. Supercritical Fluid Recrystallization: Another novel nanosizing and solubilisation

technology whose application has increased in recent years is particle size

reduction via supercritical fluid

(SCF) processes. Supercritical fluids (e.g. carbon dioxide) are fluids whose

temperature and pressure are greater than its critical temperature (Tc) and

critical pressure (Tp), allowing it to assume the properties of both a liquid

and a gas. At near-critical temperatures, SCFs are high compressible, allowing

moderate changes in pressure to greatly alter the density and mass transport

characteristics of a fluid that largely determine its solvent power. Once the

drug particles are solubilised within SCF, they may be recrystallised at

greatly reduced particle sizes.

4. Use of Surfactants: Surfactants

are very useful as absorption enhancers and

enhance both dissolution rate as well as permeability of drug. They enhance

dissolution rate primarily by promoting wetting and penetration of dissolution

fluid into the solid drug particles. They are generally used in concentration

below their critical micelle concentration (CMC) values since above CMC, the

drug entrapped in the micelle structure fails to partition in the dissolution

fluid. Nonionic surfactants like polysorbates are widely used. Examples of

drugs whose bioavailability have been increased by use of surfactants in the

formulation include steroids like spironolactone.

5. Use of Salt Forms: Salts

have improved solubility and dissolution characteristics in comparison to the original drug. It is generally accepted that

a minimum difference of 3 units between the pKa value of the group and that of

its counterion is required to form stable

salts. Alkali metal salts of acidic drugs like penicillins and strong acid

salts of basic drugs like atropine are more water-soluble than the parent drug.

Factors that influence salt selection are physical and chemical properties of

the salt, safety of counterion, therapeutic indications and route of

administration.

Salt formation does have its limitations –

·

It is not feasible to form salts

of neutral compounds.

·

It may be difficult to form salts

of very weak bases or acids.

·

The salt may be hygroscopic,

exhibit polymorphism or has poor processing characteristics.

·

Conversion of salt to free acid

or base form of the drug on surface of solid dosage form that prevents or

retards drug release.

·

Precipitation of unionised drug

in the GI milieu that has poor solubility.

6. Use of Precipitation Inhibitors: A

significant increase in free drug concentration above equilibrium solubility results in supersaturation, which can

lead to drug precipitation or crystallization. This can be prevented by use of

inert polymers such HPMC, PVP, PVA, PEG, etc. which act by one or more of the

following mechanisms -

·

Increase the viscosity of

crystallization medium thereby reducing the crystallization rate of drugs.

·

Provide a steric barrier to drug

molecules and inhibit crystallization through specific intermolecular interactions

on growing crystal surfaces.

·

Adsorb onto faces of host

crystals, reduce the crystal growth rate of the host and produce smaller

crystals.

7. Alteration of pH of the Drug Microenvironment: This can be achieved in two ways—in situ salt formation, and addition of

buffers to the formulation e.g. buffered aspirin tablets.

8. Use of Amorphs, Anhydrates, Solvates and Metastable Polymorphs: Depending upon the internal structure of the solid drug, selection of

proper form of drug with greater solubility is important. In general, amorphs

are more soluble than metastable polymorphs, anhydrates are more soluble than

hydrates and solvates are more soluble than non-solvates.

9. Solvent Deposition: In this

method, the poorly aqueous soluble drug such as nifedipine is dissolved in an organic solvent like alcohol and

deposited on an inert, hydrophilic, solid matrix such as starch or

microcrystalline cellulose by evaporation of solvent.

10. Precipitation: In this method, the poorly

aqueous soluble drug such as cyclosporine

is dissolved in a suitable organic solvent followed by its rapid mixing with a

non-solvent to effect precipitation of drug in nanosize particles. The product

so prepared is also called as hydrosol.

11. Selective Adsorption on Insoluble Carriers: A highly active adsorbent such as

the inorganic clays like bentonite can enhance the dissolution rate of

poorly water-soluble drugs such as griseofulvin, indomethacin and prednisone by

maintaining the concentration gradient at its maximum. The two reasons suggested

for the rapid release of drugs from the surface of clays are—the weak physical

bonding between the adsorbate and the adsorbent, and hydration and swelling of

the clay in the aqueous media.

12. Solid Solutions: The three

means by which the particle size of a drug can be reduced to submicron level are—

·

Use of solid solutions,

·

Use of eutectic mixtures, and

·

Use of solid dispersions.

In all these cases, the solute is frequently a

poorly water-soluble drug acting as the guest

and the solvent is a highly water-soluble compound or polymer acting as a host or carrier.

A solid

solution is a binary system

comprising of a solid solute molecularly dispersed in a solid solvent. Since the two components crystallize together

in a homogeneous one phase system,

solid solutions are also called as molecular

dispersions or mixed crystals.

Because of reduction in particle size to the molecular level, solid solutions

show greater aqueous solubility and faster dissolution than eutectics and solid

dispersions. They are generally prepared by fusion method whereby a physical

mixture of solute and solvent are melted together followed by rapid

solidification. Such systems, prepared by

fusion, are often called as melts e.g. griseofulvin-succinic acid (Fig. 11.5). The griseofulvin from such solid solution dissolves 6 to

7 times faster than pure griseofulvin.

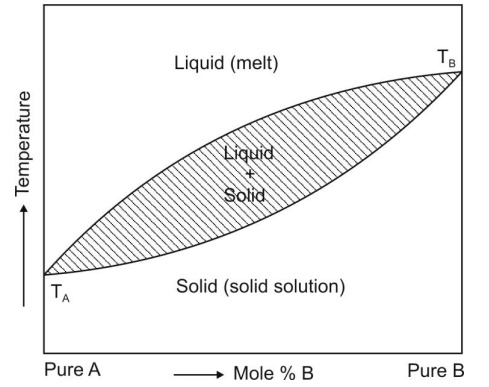

Fig. 11.5 Binary phase diagram for continuous solid solution of A and B. TA and

TB are melting points of pure A and pure B respectively.

If the diameter of solute molecules is less than

60% of diameter of solvent molecules or its volume less than 20% of volume of

solvent molecule, the solute molecule can be accommodated within the

intermolecular spaces of solvent molecules e.g. digitoxin-PEG 6000 solid solution.

Such systems show faster dissolution. When

the resultant solid solution is a

homogeneous transparent and brittle system, it is called as glass solution. Carriers that form glassy structure are citric acid, urea, PVP and

PEG and sugars such as dextrose, sucrose and galactose.

Solid solutions can be classified on two basis –

A. Miscibility between the drug and the carrier – on this basis the solid

solutions are divided into two

categories –

1. Continuous solid solution is the one in which both the drug

and the carrier are miscible in all

proportions. Such a solid solution is not reported in pharmaceutical literature.

2. Discontinuous solid solution is the one where solubility of

each of the component in the other

is limited (see fig. 11.5).

B. Distribution of drug in carrier structure – on this basis the solid

solutions are divided into two

categories –

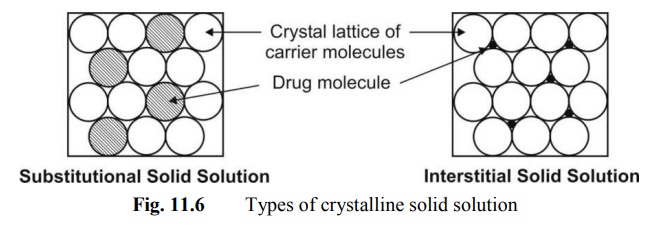

1. Substitutional crystalline

solid solution is the one in which the drug molecules substitute for the carrier molecules in its crystal lattice. This happens when the drug and

carrier molecules are almost of same size.

2. Interstitial crystalline solid

solution is the one in which the drug molecules occupy the interstitial spaces in the crystal lattice of carrier

molecules. This happens

when the size of drug molecule is 40% or less than the size of carrier

molecules (fig. 11.6).

The two mechanisms suggested for enhanced

solubility and rapid dissolution of molecular dispersions are:

·

When the binary mixture is

exposed to water, the soluble carrier dissolves rapidly leaving the insoluble

drug in a state of microcrystalline dispersion of very fine particles, and

·

When the solid solution, which is

said to be in a state of randomly arranged solute and solvent molecules in the

crystal lattice, is exposed to the dissolution fluid, the soluble carrier

dissolves rapidly leaving the insoluble drug stranded at almost molecular

level.

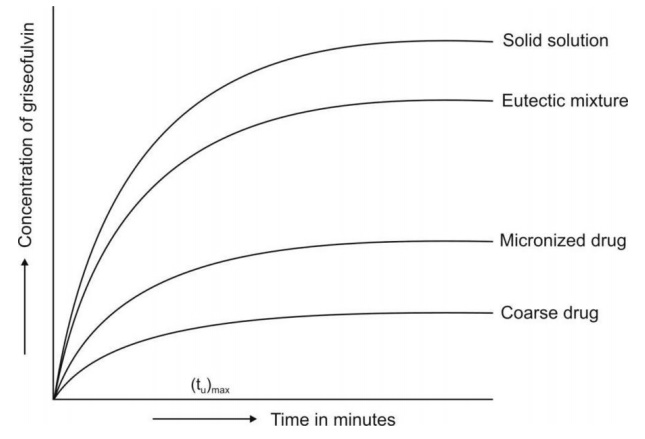

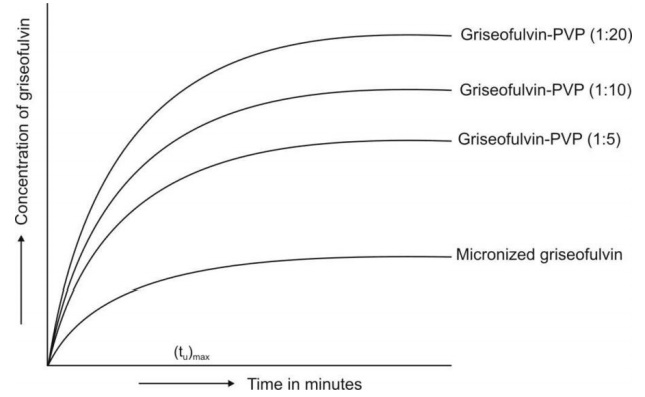

Fig. 11.7 shows a comparison between the

dissolution rates of different forms of griseofulvin.

Fig. 11.7 Dissolution rates of griseofulvin as coarse particles, as micronized particles

and as eutectic and solid solution with succinic acid.

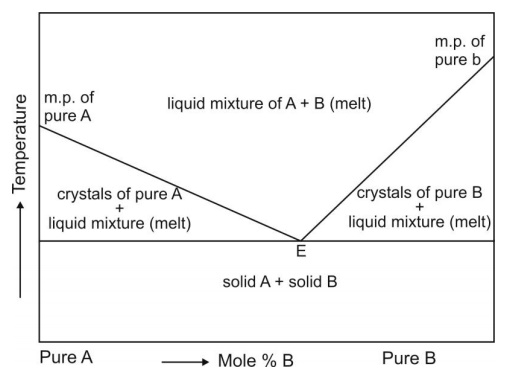

13. Eutectic Mixtures: These

systems are also prepared by fusion method. Eutectic melts differ from solid solutions in that the fused melt of

solute-solvent show complete miscibility but negligible solid-solid solubility

i.e. such systems are basically

intimately blended physical mixture

of two crystalline components. A phase diagram of two-component system is

shown in Fig. 11.8. When the eutectic mixture is exposed to water, the soluble

carrier dissolves leaving the drug in a microcrystalline state which

solubilises rapidly.

Fig. 11.8 Simple binary phase diagram

showing eutectic point E. The eutectic composition

at point E of substances A and B represents the one having lowest melting

point.

Examples of eutectics include paracetamol-urea,

griseofulvin-urea, griseofulvin-succinic acid, etc. Solid solutions and

eutectics, which are basically melts, are easy to prepare and economical with

no solvents involved. The method, however, cannot be applied to:

·

Drugs which fail to crystallize

from the mixed melt.

·

Drugs which are thermolabile.

·

Carriers such as succinic acid

that decompose at their melting point. The eutectic product is often tacky,

intractable or irregular crystal.

14. Solid Dispersions: These are

generally prepared by solvent or co-precipitation method whereby both

the guest solute and the solid carrier solvent are dissolved in a common

volatile liquid solvent such as alcohol. The liquid solvent is removed by

evaporation under reduced pressure or by freeze-drying which results in

amorphous precipitation of guest in a crystalline carrier. Thus, the basic difference between solid dispersions and solid solutions/eutectics is

that the drug is precipitated out in an amorphous form in the former as opposed

to crystalline form in the latter; e.g.

amorphous sulphathiazole in crystalline urea. Such dispersions are often

called as co-evaporates or co-precipitates. The method is

suitable for thermolabile substances but has a number of disadvantages like

higher cost of processing, use of large quantities of solvent, difficulty in

complete removal of solvent, etc. The carriers used are same as for eutectics

or solid solutions. With glassy materials, the dispersions formed are called as

glass dispersions or glass suspensions. Fig. 11.9 shows

comparative dissolution rates of griseofulvin

from PVP dispersions. Other polymers such as PEG and HPMC are also employed to

prepare solid dispersions of poorly water-soluble drugs such as nifedipine and

itraconazole.

Fig. 11.9 Dissolution rate enhancement of

griseofulvin by solid dispersion technique.

Preparation of solid dispersions also presents

several limitations –

·

Since the carrier is hydrophilic

and the drug is hydrophobic, it is difficult to find a common solvent to

dissolve both components.

·

The product is often soft, waxy

and possesses poor compressibility and flowability.

·

Physical instability of the solid

dispersion.

·

Difficulty in preparation of a

reproducible product.

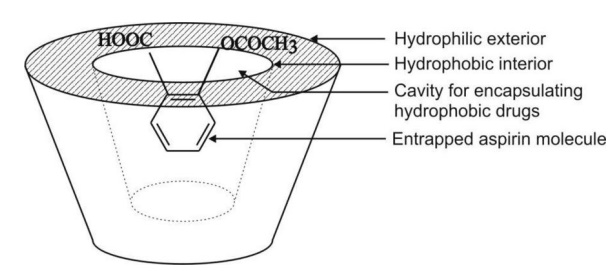

15. Molecular Encapsulation with Cyclodextrins: The beta- and gamma-cyclodextrins and several of their derivatives are

unique in having the ability to form molecular inclusion complexes with

hydrophobic drugs having poor aqueous solubility. These bucket-shaped

oligosaccharides produced from starch are versatile in having a hydrophobic

cavity of size suitable enough to accommodate the lipophilic drugs as guests;

the outside of the host molecule is relatively hydrophilic (Fig. 11.10). Thus,

the molecularly encapsulated drug has greatly improved aqueous solubility and

dissolution rate. There are several examples of drugs with improved

bioavailability due to such a phenomenon — thiazide diuretics, barbiturates,

benzodiazepines and a number of NSAIDs.

Fig. 11.10 Functional and structural feature

of a cyclodextrin molecule showing an encapsulated

drug.

16. Spherical Crystallization: add some text

Related Topics