Grinding Equipment

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Size, Reduction and Classification

The following equipment is in regular use for dry grinding pharmaceutical materials: edge and end runner mills, hammer mill, pin mill, and ball mill.

GRINDING EQUIPMENT

The

following equipment is in regular use for dry grinding pharmaceutical

materials: edge and end runner mills, hammer mill, pin mill, and ball mill.

The

fluid energy mill is becoming widely used for the production of superfine

powders. The ball mill and the colloid mill are used for wet grinding and the

production of liquid dispersions. The end runner mill and adaptations of the

roll mill may be used to comminute and disperse powders in semisolid bases, as,

for example, in the production of ointments. These mills and the vibratory mill

are described below.

Edge and End Runner Mills

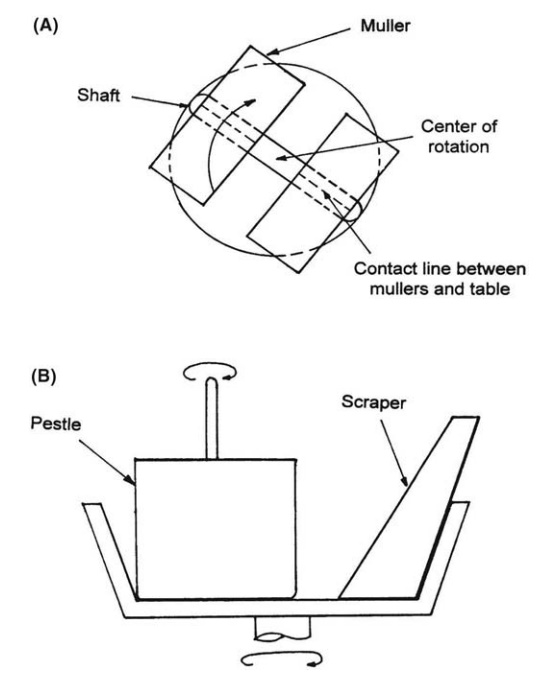

The

edge runner mill consists of one or two heavy granite or cast iron wheels or

mullers mounted on a horizontal shaft and standing in a heavy pan. Either the

muller or the pan is driven. The material is fed into the center of the pan and

is worked outward by the action of the muller. While in the zone traversed by

the muller, comminution will occur by compression, due to the weight of the

muller, and by shear. The origin of the shear forces is indicated in Figure

12.3A. The linear velocity of the pan surface will vary over the line of contact

between muller and pan. For efficient grinding, this dimension is large

compared with the diameter of the pan. Muller and pan speeds may only coincide

on one hypothetical circle, and at other positions, a varying amount of slip

must occur. A scraper continually moves material from the perimeter of the pan

to the grinding zone.

The

end runner mill is similar in principle and consists of a rotating pan or

mortar made of cast iron or porcelain. A heavy pestle is mounted vertically

within the pan in an off-center position. This arrangement is shown in Figure

12.3B. The mechanism of size reduction is compression due to the weight of the

pestle, and shear. The latter is developed by the relative movement of muller

and pan, which varies over the face of the muller. The muller is friction

driven by the pan through the ground material. A scraper is used to redirect

the material into the grinding zone.

Both

mills operate at slow speeds on a packed bed. Both produce mod-erately fine

powders and operate successfully with fibrous materials. Wet

FIGURE 12.3 (A) Edge runner mill and (B) end

runner mill.

Hammer Mill

The

hammer mill typifies a group of machines operating at very high speeds and

acting primarily by impact on a freely suspended particle. The term

“dis-integrator” is also used. High efficiency, which would be expected from

the operation of a free-crushing mechanism, is reduced because the blows

delivered are in excess of the minimum required for breakage.

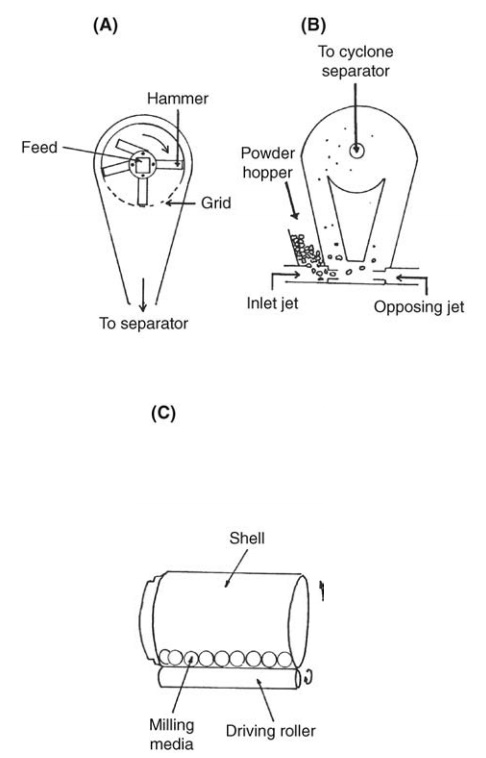

A

typical machine is shown in Figure 12.4A. It consists of a disk rotating at

speeds up to 8000 rpm. The higher speeds are used for fine grinding in

relatively small machines. A balanced number of hammers are fitted to the disk.

These may be fixed or pivoted, presenting flat, knife, or file edges to the

material. The material is fed to the top or the center of the mill and is

broken by direct impact until it is fine enough to pass through the screen,

which forms the lower part of

FIGURE 12.4 (A) Impact mill with pivoted

hammers, (B) comminution mill, and (C) ball mill.

A range of screens are normally provided. Because of tangential

exit, the product size is considerably smaller than the screen apertures. The

disk and hammers act as a centrifugal fan, drawing large volumes of air through

the mill. Entrained dust must be separated with a bag filter or a cyclone

separator.

The

mill will process dry, crystalline materials, which do not soften under milling

conditions, and many crude drugs. The speed of rotation and the size and shape

of the screen apertures are interrelated factors controlling the size of the

product. A considerable amount of very fine powder is produced. A marked rise

in temperature can occur during passage through the mill, with consequent risk

of fusion or decomposition of susceptible drugs.

Great

versatility, derived from simple variation of screen, rotor speed, and type of

blade, is characteristic of the refined mills commonly used in the

pharmaceutical industry. The “Fitzmill” (The Fitzpatrick Company of America and

Manesty Machines Limited) and the “Apex” comminuting mill (Apex Construction

Company, London) are mobile machines constructed largely of stainless steel.

The general principle is illustrated in Figure 12.4B. Both offer a large screen

area and operate at various speeds. A reversible rotor permits the use of

blades presenting either a flat, impact face or a cutting edge to the material.

Materials are ground by high-speed operation of the impact face. The knife

edges may be used at lower speeds for wet granulation and the precision

reduction of the imperfect tablets produced during dry granulation. The mill

may be jacketed to control milling temperatures. Mixing, wet grinding, and

ointment milling may also be performed.

Pin Mill

Pin

mills consist of two horizontal steel plates with vertical projections arranged

in concentric circles on opposing faces and becoming more closely spaced toward

the periphery. The projections of the two faces intermesh. The material is fed

through the center of the stationary upper disk onto the lower revolving disk

and is propelled by centrifugal action toward the periphery. The passage

between the pins provides size reduction by impact and attrition. The material

is collected in the annular space surrounding the disks and passes to a

separator. The large volumes of air drawn through the mill are discharged

through the separator. Absence of screens and gratings provides an action that

is free from clogging. The machine is suitable for grinding soft, nonabrasive

powders, and low milling temperatures permit the processing of heat-sensitive

materials. The fineness of the grind may be varied by the use of disks with

different dis-positions of pins.

Ball Mill

The

ball mill is widely used for fine grinding. Extremely fine powders may be

produced, although milling times are often protracted. Despite simple

con-struction, the mill is extremely versatile. It can be used for wet or dry

grinding in continuous or batch processes. The latter are usually imposed by

the scale of pharmaceutical operations. The mill is closed. Sterility can

therefore be main-tained or an operation can be conducted in an inert

atmosphere if the process demands such conditions. Materials of widely

differing mechanical properties can be ground by the combined effects of impact

and attrition characteristic of the mill.

The

ball mill, in its simplest form, is illustrated in Figure 12.4C. It consists of

a rotating, hollow cylinder containing balls usually made of stainless steel or

stoneware. During grinding, the balls slowly wear and are eventually replaced.

For general purposes, the mill will therefore contain balls of different sizes,

which perform different functions. The loading of the mill varies. Typically,

the mill is half filled with balls and the material to be ground is added to

overfill the interstices between the balls. The apparent volume of the total

charge is com-monly 60% of the mill volume. In operation, the distance the

charge moves up the mill casing depends on the centrifugal force. This is a

function of the speed at which the mill rotates and the friction between charge

and mill lining. These effects determine the pattern of movement within the

mill. At low grinding speeds, the balls tumble, roll, and jump down the free

face of the charge, a pattern described as “cascading.” With increase in speed,

the pattern progres-sively changes to “cataracting” in which the balls are carried

almost to the top of the mill and fall directly onto the charge below.

The

grinding contributions of impact and attrition vary in these patterns of

movement. Attrition predominates in the cascading mill and depends, to some

extent, on the surface area of the balls. The effect can therefore be enhanced

by the use of small balls. Impact breaking becomes more important in the

cata-racting mill, the most effective action being derived from the high

kinetic energy of the larger balls, a factor also influenced by the latter’s

density.

If

there is sufficient friction between the mill lining and the charge, the latter

will “key” to the mill at higher speeds and rotate with it. This is termed

“centrifuging,” and since there is no relative movement between the balls, no

grinding occurs. The speed marking the onset of centrifuging is called the

critical speed. Theoretically, it represents conditions for which the

centrifugal and gravitational forces acting on a ball at the top of the mill

are balanced. If the mass of the ball is m, the gravitational force is given by

mg and the centrifugal force is mvc2/r,

where vc is the critical speed and r is the distance of the ball

from the axis of the mill, that is, the radius of the mill minus the radius of

the ball. These may be equated to give

vc = √(gr) (12:4)

In

practice, centrifuging does not occur until well above the theoretical critical

speed, and it varies with mill loading and the amount of slip between charge

and lining. Mills usually operate at between 50% and 80% of the critical speed.

The lower speeds are used for wet grinding and very fine dry grinding.

If

a low coefficient of friction permits extensive slipping between mill and

charge, centrifuging will not occur even at very high mill speeds. Under these

“supercritical” conditions, the grinding action differs from the pattern

described above.

By

correct choice of ball size, mill speed, and diameter, the ball mill may be

used to grind material of widely different particle size. In coarse dry grinding,

the energy is associated with the largest ball falling and the diameter of the

mill must be sufficient to break the largest particle. Very fine grinding, on

the other hand, is best effected by the attrition between a large number of

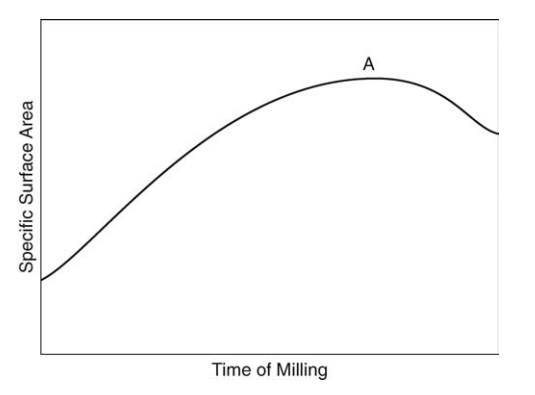

small balls. The most important limiting factor in the production of very fine

particles by milling is agglomeration. Ultimately, the reduction of new surface

by rebonding may equal the increase in surface due to fracture. This is shown

as point A in the relation of specific surface area and milling time given in

Figure 12.5. With further grinding, the effective particle size may actually

increase. Agglomeration during fine dry grinding is usually more severe than

that in wet grinding. In both cases, however, additives can sometimes be used

to limit its effect.

The

ball mill also provides a simple mechanical means of producing dis-persions of

solids in liquids. Wet grinding depends on the attrition characteristic of the

cascading mill. The smaller the balls, the greater the effect and the greater

the viscosity of the suspension. The latter should not prevent the correct

FIGURE 12.5 The effect of particle agglomeration during milling.

Where their use is permissible, the addition of surface-active

agents may greatly accelerate the process by preventing reaggregation of the

particles. Surface-active agents can also alter the physical properties of the

solid, lowering the breaking strain and rendering the particle more brittle. A higher

ratio of solids to liquid, which aids efficient milling, is possible if the

system is deflocculated.

In

large-scale, continuous installations, the mill may be modified to apply

grinding forces appropriate to the size of particle being ground. In the tube

mill, the ratio of length to diameter is greatly increased and the mill is

divided into several compartments, each containing balls of different average

size. The coarse material first enters the compartment containing the largest

balls. It is then conveyed to successive compartments containing smaller balls

and capable of progressively finer grinding. In the Hardinge conical ball mill,

natural segre-gation is induced by the conical shape. The largest balls operate

at the largest diameter and, through the kinetic energy acquired during the

extensive fall, create high-impact stresses suitable for breaking coarse

particles. The material first passes through this region. With further progress

through the mill, the greater surface presented by the smaller balls promotes

finer grinding by attrition.

Vibratory Mill

In

the ball mill, the energy for grinding is derived from the acceleration of the

balls in a gravitational field. Under normal conditions, the latter limits the

speed at which a mill of a given diameter can be run and therefore limits the

rate at which energy can be applied to the process. Long milling times are

characteristic of the ball mill. The advantage of vibratory milling is centered

mainly on this limitation since it is possible, by this method, to develop

accelerations much greater than those induced by the earth’s gravitational

field. Grinding can be more energetic, and milling times can be greatly

reduced.

A

simple form of vibratory mill consists of a mill body containing the grinding

media, usually of porcelain or stainless steel balls. The mill body is

supported on springs, which permit an oscillatory movement. This vibration is

usually, but not necessarily, in a vertical plane. The suspended mass is

main-tained in a state of forced vibration by some means such as the rotation

of a shaft on which unbalanced weights are mounted. The charge is subjected to

move-ments of high frequency and small amplitude. The resultant chattering of

the mill gives comminution by attrition. Characterized by relatively high-speed

grinding, the mill is usually more flexible than the ball mill, charging and

dis-charging and adaption to continuous processing being much easier. The more

efficient use of the energy applied and the shorter grinding times usually result

in lower milling temperatures than that found in a ball mill. Construction,

however, is more complex, and the feed size of the material is limited to

approximately 0.25 in. or less. The mill is not suitable for grinding resilient

materials, which cannot be ground by impact since the shear forces developed

are less than those found in a ball mill.

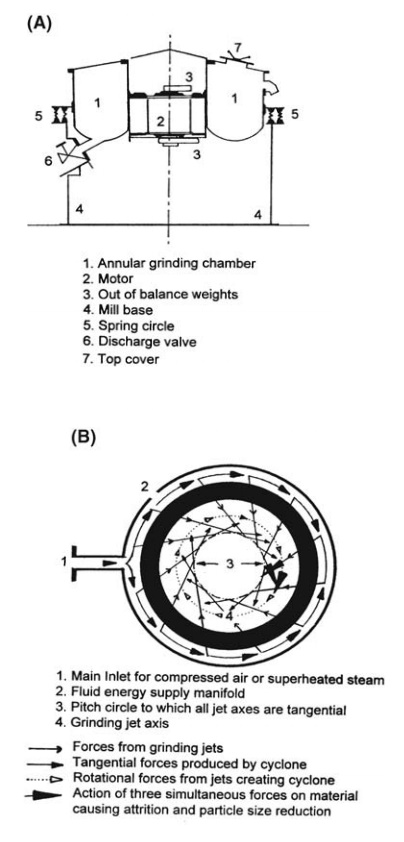

A

refined example of this principle is found in the Podmore-Boulton vibro-energy

mill, shown in Figure 12.6A. This consists of an annular grinding chamber generally

accommodating a medium of small cylinders. These align coaxially in a

three-dimensional vibratory field to give close packing and line

FIGURE 12.6 Diagrams of (A) vibro-energy mill and (B) fluid energy mill.

This, it is claimed, gives preferential grinding of

coarse material, leading to products with narrow particle size distributions.

Fluid Energy Mill

The

fluid energy mill offers an alternative method of producing very fine powders.

The term “micronizer” is in general use and is a trade name coined by a company

that originated a particular type of fluid energy mill. In all fluid energy

mills, the grinding results mainly from attrition between the particles being

ground, the energy inducing movement of the particles being supplied in the

form of compressed fluids. Air and steam are widely used.

A

common type of fluid energy mill is illustrated in Figure 12.6B. The material

is blown into the grinding chamber through a venturi feed placed at its

perimeter. The compressed fluid enters the chamber through nozzles tangential

to a hypothetical circle within the grinding chamber. The particles are

violently accelerated by the rotating fluids and are subjected to the influence

of successive nozzles. Grinding results from impact between particles, which

are then sub-jected to the intense classifying action of the circulating fluid.

Oversize particles remain in the grinding zone, while fine powder and spent

grinding fluid spiral to the central outlet.

For

a given machine, the size reduction depends on the size of the feed, its rate

of introduction to the grinding chamber, and the pressure of the grinding

fluid. The most important machine factors are the geometry of the grinding

chamber and the number and angle of the nozzles.

Powders

with all particles below a few microns may be quickly produced by this method.

The disadvantage of high capital and running costs may not be so serious in the

pharmaceutical industry because of the high value of the materials that are

often processed. For grinding drugs, the mill is usually made of stainless steel. Large volumes of air compressed

to about 6.89 x 105 N/m2 must be provided.

Colloid Mills

Colloid

mills are a group of machines used for wet grinding and dispersion. They

operate by shearing relatively thin layers of material between two surfaces,

one of which is moving at a high angular velocity relative to the other.

Although very fine dispersions can be produced, they are not, as the name

implies, of colloidal dimensions. Colloid mills are also widely used in the

preparation of emulsions.

A

typical colloid mill consists of a stator and a rotor with flat working

surfaces. These are often made of stainless steel or carborundum. The clearance

is adjustable from virtually zero upward. The rotor is rotated at several

thou-sand revolutions per minute, and the slurry of already fine material

passes through the clearance under the action of centrifugal forces.

Surface-active agents fulfill the same function in colloid mills as in ball

milling.

Roller Mills

Roller

mills may be used to grind pastes and other plastic dispersions. They operate

by inducing crushing and shearing forces in a thin layer of the paste as it

passes through the narrow clearance between two rollers. Commonly, shear forces

are intensified by the differing peripheral velocity of the rolls. The

clearance between the rolls is variable and depends on the plasticity of the

mass, the gap increasing as the stiffness of the material increases. With thin

pastes, the milling action is similar to the colloid mill.

Related Topics