The Operation of Mills

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Size, Reduction and Classification

In some operations, such as those in which ores are processed, size reduction may constitute a major proportion of total process costs.

THE OPERATION OF MILLS

In

some operations, such as those in which ores are processed, size reduction may

constitute a major proportion of total process costs. The efficiency with which

energy is utilized is, therefore, of great importance. Drugs, on the other

hand, fall into a class of materials that are high in cost and are processed in

relatively small quantities. The contribution of grinding to total costs is,

there-fore, smaller, and the choice of machine can usually be made on

technological rather than economic grounds. Generally, drugs are easy to grind.

The operation is classified as fine grinding if the bulk of the product passes

a 200-mesh screen (7.6 x 10-5 m) or as superfine grinding if a

powder of a few microns or less is required. Most pharmaceutical grinding falls

into these classes, although coarser grinding is applied to vegetable drugs

before extraction.

Heywood

has stated that any type of crushing or grinding machine exhibits optimal

comminution conditions for which the ratio of the energy to new surface is

minimal (Heywood, 1957). If finer grinding is attempted in such a machine, the

ratio will be increased. Mills may thus become grossly inefficient if called

upon to grind at a size for which they were not designed. A limited size

reduction ratio is imposed upon a single operation, larger ratios being

obtained by the adoption of several stages, each employing a suitable mill. The

fluid energy mill, which presents a size reduction ratio of up to 400, is

exceptional.

A

low retention time is inherent in free-crushing machines. Little over-grinding

takes place, and the production of excessive undersize material or “fines” is

avoided. Protracted milling times are found with many slow-speed mills, with

the result that considerable overgrinding takes place. Accumulation of product

particles within the mill reduces the effectiveness of breaking stresses, and

the efficiency of milling progressively decreases. This is typical of

“open-circuit” grinding, in which the material is passed only once through the

mill, remaining until virtually all has reached the required product size. An

overall increase in efficiency is secured in “closed-circuit” grinding. Product

particles are removed from the mill by means of a current of air or liquid or,

alternatively, by screens. The removed product may then be classified and any

oversize material returned to the mill. Adoption of closed-circuit grinding

techniques is only possible on a relatively large scale. On a smaller scale,

the effect can be simulated by periodic classification of the entire mill

contents and the removal of material that has reached the required size.

Dry and Wet Grinding

Between

the approximate limits of 5% and 50% moisture, materials cake and do not flow.

Both factors oppose effective grinding. Dry grinding is carried out at low

moisture contents, the upper limit depending on the nature of the material.

Although 5% or more moisture may be permissible for vegetable drugs, it would

prove excessive during the milling of a coarse, impervious solid.

Wet

grinding is a common procedure when a fluid suspension is required and drying,

which would prove a significant drawback, is unnecessary. An excellent

dispersion can be produced simultaneously, and in some operations, this

provides the primary objective, size reduction being of secondary impor-tance.

Wet grinding may also be adopted when the size reduction achieved during dry

grinding is prematurely limited by aggregation.

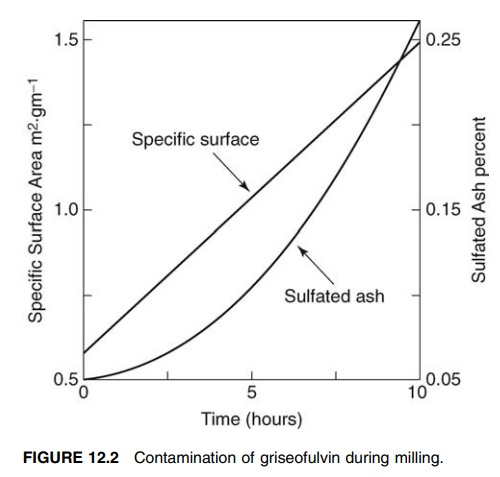

FIGURE 12.2 Contamination of griseofulvin during milling.

Certain

general advantages are secured during wet grinding. These include an increased

mill capacity, a lower energy consumption, the elimination of hazards from

dust, and easier handling of materials. The principal disad-vantage, apart from

the possible inclusion of a drying stage, is the increased wear of the grinding

medium.

Contamination

Wear

of grinding elements, which occurs in all mills, results in the contamina-tion

of the product. This factor influences the choice of constructional materials,

and ceramics and stainless steel are most commonly used. Contamination is

normally slight. However, in the protracted periods often associated with the

production of very fine powders, it may become severe. This is illustrated by

the data presented in Figure 12.2, which shows a progressive increase in a

sulfated ash value of the material due to wear of the ceramic mill.

Closed

mills, preventing the ingress of bacteria, must be used for grinding sterile

materials.

Temperature Sensitivity

Care

must be exercised during the milling of temperature-sensitive materials,

especially when a very fine product is required. Caking results if the

softening point is exceeded. Materials may be chilled before grinding, or

facilities for cooling the mill during grinding may be provided. Waxy solids

can be suc-cessfully ground with dry ice, the low temperatures conferring

brittle charac-teristics on the material. Chemical degradation may occur at

high grinding temperatures. Oxidative changes can be prevented by grinding in

an inert atmosphere such as nitrogen.

Structural Changes

Several

examples of change of physical structure during very fine grinding have been

reported. Gammage and Glasson found changes in the crystal form of calcium

carbonate after ball milling (Gammage and Glasson, 1963). Distortion of the kaolinite

lattice during very fine grinding was reported by Gregg (Gregg, 1955).

Cleverley and Williams found that various barbiturate polymorphs were formed

during grinding (Cleverley and Williams, 1959). Changes such as these could

affect solubility and other physical characteristics, which, in turn, might

influence formulation and therapeutic value.

Dust Hazards

Hazards

from dust may become acute during dry grinding. Extremely potent materials

require dust-proofing of machines and the supply of dust-proof clothing and

masks to operators. Danger may also arise from the explosive nature of many

dusts.

Related Topics