Manufacturing of tablets

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Tablets

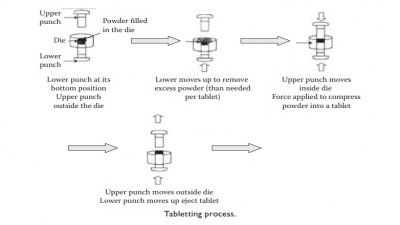

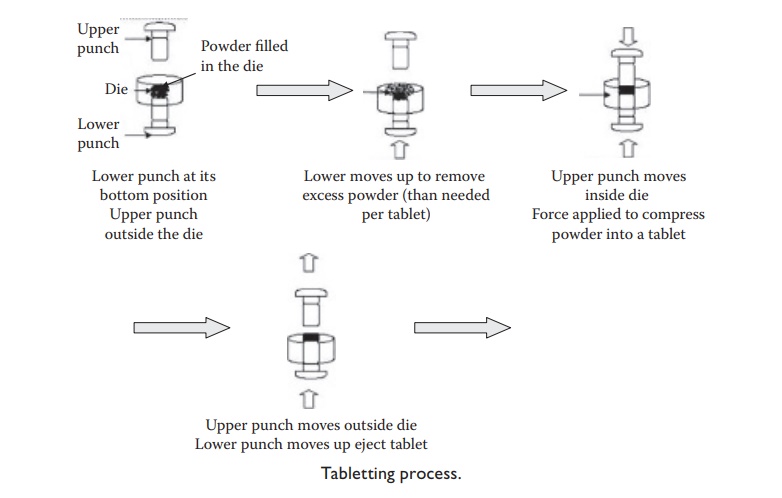

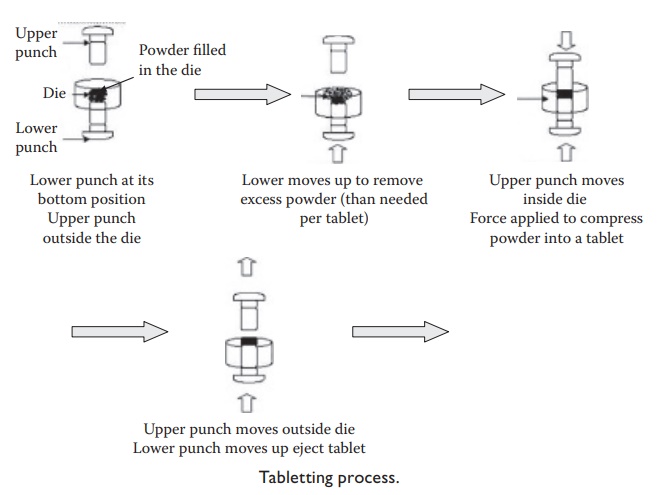

Tableting involves compression of a powder blend in a die cavity between the upper and the lower punches.

Manufacturing of

tablets

Requirements for tableting

As

shown in Figure 20.2, tableting involves

compression of a powder blend in a die cavity between the upper and the lower

punches. Several punches and dies are arranged on three rotary turrets on a

high-speed rotary tablet press that move concurrently in a circular motion as

the tablets are made. As the turret moves, the powder is fed into the dies at

one port through a

Figure 20.2 Tabletting process.

·

Uniform flow of blend into the die cavity through a hopper

and feedframe.

·

Nonsegregation of powder blends in the hopper and during

loading in the die cavity.

·

Compactibility (ability to reduce in volume and compress on

applica-tion of force by the punches) of the powder in the die cavity during

compression.

·

Nonsticking of the powder blend to walls of dies and

surfaces of punches.

·

Adequate cohesion of the powder blend to form a strong

tablet.

Powder flow and compressibility

Powder

flow is required for transporting the materials through the hopper of a

tableting machine and roller compactor (for dry granulation or roller

compaction-based processes). Inadequate powder flow can lead to variable die

filling, which produces tablets that vary in weight, drug content, and strength

(hardness). Therefore, steps must be taken to ensure that the proper powder

flow is maintained. Incorporation of a glidant and/or a lubricant into the

formulation enhances the powder flow. Increasing the sphericity of particles

also improves the flow. Processes such as spray drying, fluid-bed granulation

or extrusion spheronization increase the sphericity of granules. In addition,

increasing the density of granules, such as by granulation, also improves the

powder flow. The most popular method of increasing the flow properties of

powder is by granulation. As discussed earlier, granulation could be either dry

granulation, which does not use a granulating fluid, or wet granulation, which

involves wetting with a fluid followed by drying.

Compressibility

is the property of forming a stable, intact compact mass when pressure is

applied. Some materials compress better than others do. Compressibility is an

outcome of the extent of plastic deformation that a material can undergo

combined with cohesive forces among the powder blend that will keep the

material in the compressed state. Most materi-als exhibit different degrees of

elastic recovery, that is, expansion toward original higher volume on removal

of stress. Low elastic recoveries coupled with high plastic deformability and

high interparticle adhesion promote the formation of strong compacts at low

compression forces.

Granulation

generally improves compressibility. Materials that do not compress well produce

soft tablets.

Types of manufacturing processes

Based

on the characteristics of the starting materials that influence the properties

of the powder blend, three general processes are used for prepar-ing

granulation blends for compression:

·

Direct compression

·

Dry granulation or

roller compaction

·

Wet granulation

The

purpose of both wet and dry granulation is to improve the flow of the mixture

and to enhance its compression properties by increasing particle size, density,

and sphericity. The selection among these processes is based on the

physicomechanical properties of the API and the raw material blend (API with

excipients). For example, stability of the API to other ingredients used for

preparing granulation blends and processing conditions (e.g., use of water

during wet granulation) is critical. For example, dry granulation may be preferred

for moisture and/or heat sensitive APIs.

1. Direct

compression:

Direct compression is the preferred method if powder blend has adequate flow, compactibility, and cohesion with

low segregation potential. This is the simplest process that involves the least

extent of material handling. Direct compression involves simply mixing the

required ingredients and compressing them into tablets on the press.

2. Dry granulation: Dry granulation is

preferred in circumstances where

powder flow, cohesion, and/or segregation potential need to be improved, but

compactibility is adequate. This process involves com-pacting a powder blend.

It can be carried out by either of two processes: (a) slugging, which involves

compression using large punches and dies in a tablet press; or (b) roller

compaction, which involves forcing the powder blend between two counterrotating

rolls that are pressed together under hydraulic pressure. This squeezes the

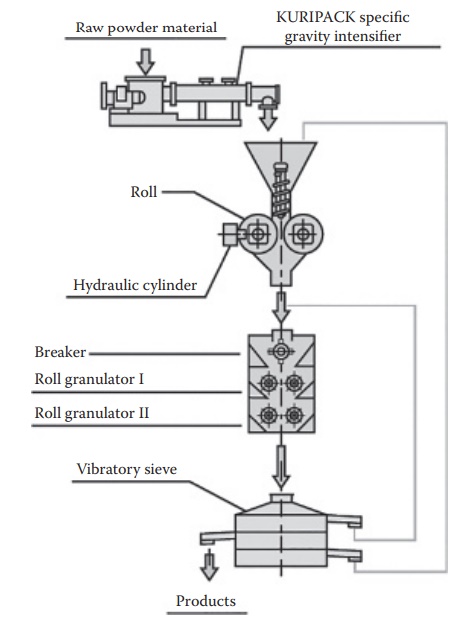

powder blend into a solid cake between rollers. As shown in Figure 20.3, the compacted material is milled to form

granules, which are generally larger in par-ticle size than starting powder

blend. These granules are then mixed with extragranular excipients and

compressed on the tablet press.

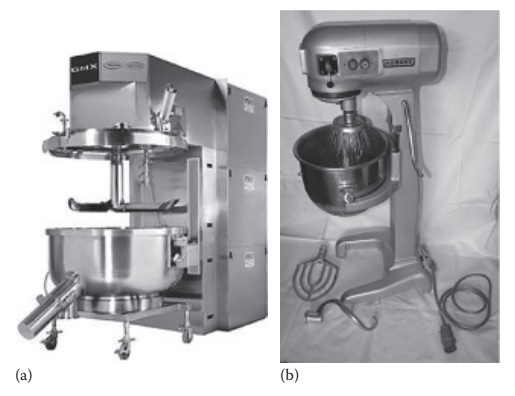

Figure 20.3 (a) A high shear granulator. (From Vector Corporation, http://www. vectorcorporation.com.) and (b) a low shear granulator. (From Hobart Corporation, http://www.hobartcorp.com. With Permission.)

3. Wet granulation: Wet granulation is preferred when compactibility of the powder is not very high and there is a need to improve the flow, cohesion, and/or segregation potential of the powder blend. The powder blend is loaded in a granulator (vessel with a rotating blade to mix the powder, Figure 20.4) and granulated with a solu-tion of the binder or water (if a dry binder is added to the powder mixture). Water is the most widely used blender vehicle. The use of nonaqueous granulation liquids, such as ethanol, is no longer pre-ferred for safety and environmental reasons. The formed granules are dried in a tray or fluid bed dryer at moderately elevated tempera-tures. Dried granules are then mixed with extragranular excipients and compressed on the tablet press.

Figure 20.4 A roller compaction process.

(From Kurimoto Ltd., http://www.kurimoto. co.jp. With Permission.)

a. Low or high-shear

wet granulation: Depending on the design of the granulator, wet granulation could impart low or high levels of

shear to the powder blend and are termed accordingly. For example, a flat-bottom

bowl granulator with horizontal blades that move in a circular motion at the

bottom of the powder bed (Figure 20.4a) leads

to high shear, whereas the use of verti-cal blades in an oval bowl (Figure 20.4b) lead to low shear. The extent of shear

can affect porosity, compactibility, and density of granules. Low-shear

granulation generally yields higher porosity, higher compactibility, and lower

density of the formed granules. A choice between low- and high-shear

granulation is based on the sensitivity of the desired product quality

attributes to process conditions.

b. Fluid-bed

granulation:

Fluid-bed granulation involves the spray of

the granulating liquid on the fluidized powder bed. This process combines

the drying step with the granulation step. In this pro-cess, the evaporation of

the granulating liquid is concurrent with the granulation of the powder blend.

It is a relatively slow, but a well-controlled process that leads to the

generation of granules, which are more porous, less dense, and more uniform in

shape and size.

4. Moisture-activated

dry granulation: Other processes commonly employed for preparing powder blend for compression involve a

com-bination of the three basic processes. For example, MADG involves spraying

of a minimum amount of water on the powder blend before compression to improve

powder adhesion.

5.

Continuous granulation: Use a continuous granulation process mini-mizes the

material transfers and enables flexibility of batch size. Continuous processes

are based on a tunnel or channel of powder flow with sequential positions where

different steps of a process—such as water addition, drying, and milling in the

case of wet granulation— are carried out in tandem.

Packaging and handling considerations

Following

compression and coating, tablets are stored in tight containers and protected

from high temperature and humidity places. Products that are prone to

decomposition by moisture generally are copackaged with des-iccants, such as

silicon dioxide. Drugs that are adversely affected by light are packaged in

light-resistant containers.

Related Topics