Types of tablets

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Tablets

Depending on the physicochemical properties of the drug, site and extent of drug absorption in the gastrointestinal (GI) tract, stability to heat, light, or moisture, biocompatibility with other ingredients, solubility, and dose.

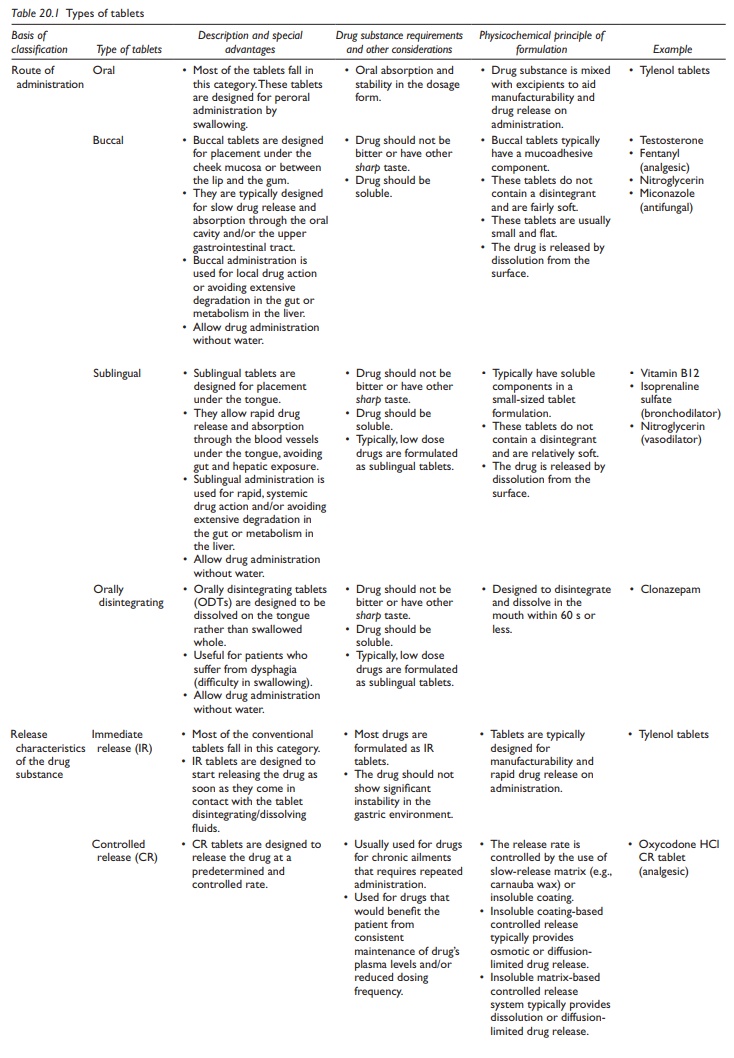

Types of tablets

Depending

on the physicochemical properties of the drug, site and extent of drug

absorption in the gastrointestinal (GI) tract, stability to heat, light, or

moisture, biocompatibility with other ingredients, solubility, and dose, the

following types of tablets are commonly formulated (Table

20.1):

1. Swallowable tablets

The

most common types of tablets are swallowed whole. These tablets dis-integrate

and release their contents in the GI tract.

2. Effervescent tablets

These

tablets are formulated to allow dissolution or dispersion in water prior to

administration and should not be swallowed whole. In addition to the DS, these

tablets contain sodium carbonate or bicarbonate and an organic acid such as

tartaric acid. In the presence of water, these additives react, liberat-ing

carbon dioxide, which acts as a disintegrator and produces effervescence. The

drug is released into the aqueous medium as a solution, if it is highly

soluble, or suspension. Ingestion of a dissolved or finely dispersed drug

pro-vides a rapid rate of drug absorption. Therefore, effervescent tablets can

be suitable for acute conditions that require immediate relief, such as pain

and gastric acidity. For example, cephalon’s fentanyl effervescent tablet can

be used to reduce the intensity of breakthrough pain in cancer patients.

3. Chewable tablets

Chewable

tablets are used when a faster rate of dissolution and/or buc-cal absorption is

desired. Chewable tablets consist of the drug dispersed throughout a saccharide

base that provides mild sweetness. Flavors, sweet-eners, and colors are also

added to chewable tablets to improve palatability and organoleptic appeal. The

drug is released from the dosage form by physical disruption associated with

chewing and dissolution in the fluids of the oral cavity, and the presence of a

effervescent material. For example, some antacid tablets can be chewed to

obtain quick indigestion relief. Chewable tablets are typically prepared by

compression and usually contain mannitol or sorbitol as saccharide, mildly

sweet, fillers. Mannitol is some-times preferred as a chewable base diluent,

because it has a pleasant cooling

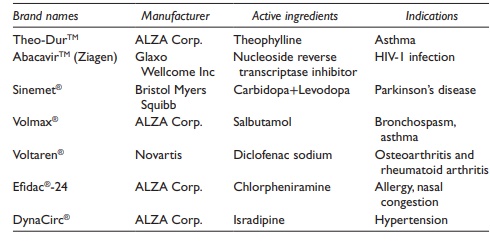

Table 20.1 Types of tablets

4. Buccal and sublingual tablets

Buccal

and sublingual tablets dissolve in the cheek pouch (buccal) or under the tongue

(sublingual). Buccal or sublingual route of drug absorption bypasses hepatic

metabolism, often referred to as the first-pass effect on oral administra-tion,

and is preferred for low dose drugs that have extensive hepatic metabo-lism.

Sublingual administration also allows rapid drug absorption, which may be

critical in cases such as nitroglycerin for chronic heart failure. Other

exam-ples include isoprenaline sulfate (bronchodilator), glyceryl trinitrate

(vasodila-tor), and testosterone tablets. These tablets are usually small and

flat, do not contain a disintegrant, and are intended for dissolution in the

local fluids.

5. Lozenges

Lozenges

are slow dissolving compressed tablets that do not contain a disin-tegrant.

Some lozenges contain antiseptics (e.g., benzalkonium) or antibiotics for local

effects in the mouth. Lozenges are also used for systemic effect, such as those

containing vitamin supplements. Lozenges are palatable and organo-leptically

appealing by the addition of flavors, sweeteners, and colors.

6. Coated tablets

Most

tablets are coated for one or more of the following reasons:

·

To prevent decomposition of drugs sensitive to air (oxygen),

light, or humidity

·

To minimize the unpleasant taste of certain drugs that may

come dur-ing partial dissolution of the drug in buccal fluids during absorption

·

To improve swallowability and palatability by increasing

surface smoothness in the mouth

·

To provide visual appeal and consistency, smooth surface

texture, and uniform distribution of color

·

To serve as anticounterfeiting medium by incorporating

tracer com-pounds in the coating material

·

To allow containment of highly potent compounds in the core

of the tablet and, thus, avoid exposure to personnel handling of the tablets

Coating

is not used on buccal, sublingual, chewable, effervescent, or dis-persible

tablets to avoid any delay in drug release due to the time required for the

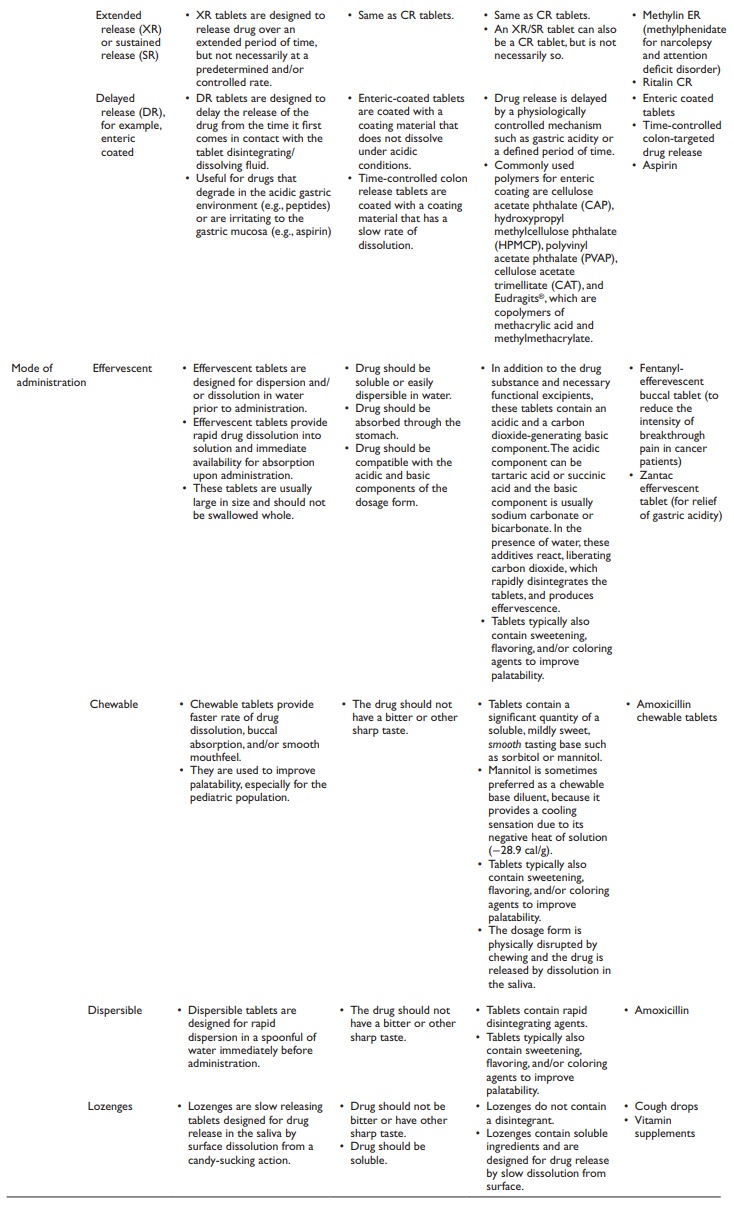

rupture or dissolution of the coating material (Table

20.2).

Coating

of core (compressed, uncoated) tablets is carried out by load-ing the tablets

in a moving, perforated pan supplied with dry hot air and spraying the coating

dispersion onto the tablet bed at a rate matched with the rate of evaporation

of the solvent. This leads to the deposition of a film

Table 20.2 Characteristics of types of tablet coatings

This process is

carried out for a sufficient duration of time to allow uniform and elegant

coverage of the entire surface of the tablet by the coating material. The

coating material consists of an opacifier (such as fine particle size titanium

dioxide), color, plasticizer (such as polyethylene glycol), and a polymer (such

as hydroxypropyl methylcellulose [HPMC] or polyvinyl alcohol [PVA]). Typically,

about 3% w/w application of the coating material provides com-plete coverage by

the formation of a thin film around the tablet. The coated tablets are called film-coated tablets.

Other

types of coated tablets are sugarcoated, gelatin-coated (gel caps), and

enteric-coated tablets. Sugarcoated tablets are produced by the application of

sucrose solution, containing preservatives, colorants, sweeteners, and flavors,

to the core with a relatively high (~30% w/w) weight buildup. Film coating has

almost completely taken over sugar coating in the pharmaceutical industry

because of shorter processing time and the smaller size of the coated tablet. A

common example of sugarcoated tablet is the M&Ms, which are consist of a

solidified liquid-chocolate center and a hard-candy shell which is a

combination of sugar and corn syrup. Characteristics of sugarcoated and

film-coated tablets are summarized in Table 20.3.

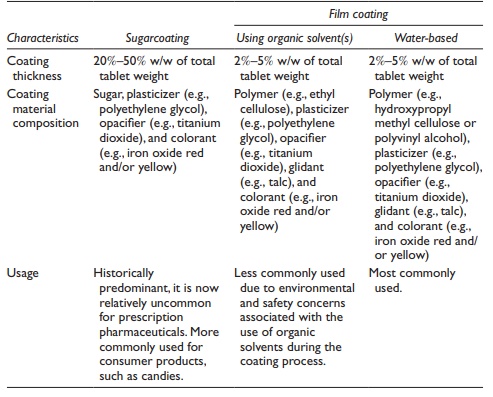

Table 20.3 Examples of sustained release tablets

Gelatin-coated

tablets, commonly known as gelcaps, are capsule-shaped compressed tablets

coated with a gelatin layer. These tablets are produced by dipping the core

tablets in a solution of gelatin with colors and preser-vatives, followed by

drying. This allows the product to be smaller than an equivalent capsule filled

with an equivalent amount of powder, and pro-vides an elegant visual appeal.

Many over-the-counter (OTC) medications are marketed as gelcaps.

7. Enteric-coated tablets

GI

fluid pH increases progressively from acidic to basic from the stomach through

the intestines to the colon. The changes in GI pH can be utilized to release a

drug at a particular physiological location in the GI tract. In particular,

oral solid dosage forms can be coated with a polymer that is insoluble at the

acidic stomach pH and soluble at basic intestinal pH. Such polymers are known

as enteric polymers and such coatings are termed enteric coatings.

Enteric-coated tablets are the tablets coated with enteric polymers. Complete

coating of the tablet with these polymers allows the polymer to form a barrier

between the core of the tablet and the surround-ing aqueous medium. Thus, the

enteric-coated tablet remains insoluble in the low pH environment of the

stomach, but dissolves readily on passage into the small intestine with its

elevated pH.

Enteric

coating is used to minimize irritation of the gastric mucosa by certain drugs

and/or protect sensitive drugs against decomposition in the acidic environment

of the stomach. For example, aspirin produces less gas-tric bleeding when

formulated as enteric-coated sustained-release (SR) tab-lets than conventional

immediate release dosage forms.

Commonly

used polymers for enteric coating are acid-impermeable poly-mers, such as

cellulose acetate phthalate (CAP), HPMC phthalate (HPMCP), polyvinyl acetate

phthalate (PVAP), and Eudragits®, which are copolymers of methacrylic acid and

methylmethacrylate. Eudragits are available in different grades. The drug

release behavior of a Eudragit-coated tablet is controlled through the ratio of

methacrylic acid copolymers. For example, the ratio of carboxyl to ester groups

is approximately 1:1 in fast dissolving Eudragit L100 and 1:2 in slow

dissolving Eudragit S100.

8. Immediate release tablets

Most

tablets (discussed earlier) are immediate release (IR) tablets, that is, they

make all the drugs available to the dissolution medium immediately on coming in

contact with the aqueous medium. The drug dissolves at a rate determined by the

composition of the dissolution medium (such as pH) and physicochemical

properties of the drug (such as solubility and particle size).

9. Controlled release tablets

In

contrast to the IR tablets, certain dosage forms, such as controlled-release

(CR) or extended-release (XR) tablets, are designed to control or extend,

respectively, the rate at which drug dissolves in the aqueous medium. Thus, CR

tablets reduce the rate of drug release to a slow, controlled rate, which is

typically zero order. XR tablets, on the other hand, extend the duration of

drug release by slowing down the rate of drug release but may not have control

on the rate (i.e., may not provide zero-order kinetics of drug release). CR or

XR tablets are sometimes also called SR tablets.

CR

tablets can reduce dosing frequency, increase patient compliance, and may

reduce side effects of certain drugs. The rate-controlling feature of the CR

tablets could be either the matrix or the film coating. Coformulating or mixing

drugs with water-insoluble polymers prepare matrix tablets. A slow dissolving

polymer matrix, such as high molecular weight HPMC, can be used to prepare SR tablets

of highly water-soluble drugs. On coming in contact with the aqueous

dissolution medium, the core tablet dissolves by surface erosion, and the rate

of surface erosion is controlled by the rate of dissolution of the polymer

matrix. For example, metformin hydrochloride XR tablets (Glucophage XR

tablets®) are matrix tablets.

Membrane-coated

SR tablets utilize an insoluble membrane to reduce or control the rate of drug

release. The insoluble membrane can be impreg-nated with a soluble polymer to

provide pores from which the drug can diffuse out or have a hole for

osmotically CR tablets. Often, a combination of IR and SR components is

included in a dosage form to provide a loading dose (by the IR component)

followed by a slow releasing maintenance dose (by the SR component). The IR and

the SR component can form two dif-ferent layers of a bilayer tablet, for

example. These components can also be mixed together and packaged in a capsule.

The SR and IR components can also be compressed together. For example, Theo-Dur®

CR tablet of theoph-ylline consists of two components: (1) a matrix of

compressed theophylline crystals and (2) coated theophylline granules embedded

in the matrix. In contact with fluids in GI tract, theophylline diffuses slowly

through the wall of the free granules, which dissolves with time. After oral

administra-tion of Theo-Dur® 300 mg tablets to human subjects, serum

theophylline concentrations over 1 mg/ml were maintained over 24 hours.

Examples

of commonly used SR drug delivery products are listed in Table 20.3.

Related Topics