Hard gelatin capsules

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Capsules

Gelatin is a colorless, almost tasteless, translucent proteinaceous substance that is brittle when dry and elastic when mixed with controlled amount of moisture.

Hard gelatin

capsules

Gelatin

is a colorless, almost tasteless, translucent proteinaceous substance that is

brittle when dry and elastic when mixed with controlled amount of moisture. It

is produced by irreversible, partial hydrolysis of collagen, which is obtained

from animal skin and bones. It forms a semisolid col-loid gel in the presence

of water, which displays a temperature-dependent gel–sol transformation and

viscoelastic flow. It has crystallites (microscopic crystals formed during the

cooling phase of manufacture of capsule shells) that stabilize the

three-dimensional gel network structure and are respon-sible for streaming

birefringence in gelatin solutions.

A

hard gelatin capsule shell consists of two pieces: a cap and a body. The body

has slightly lower diameter than the cap and fits inside the cap. They are

produced empty and are then filled in a separate operation. During the capsule

filling unit operation, the body is filled with the medicament, fol-lowed by

the insertion of the cap over the body.

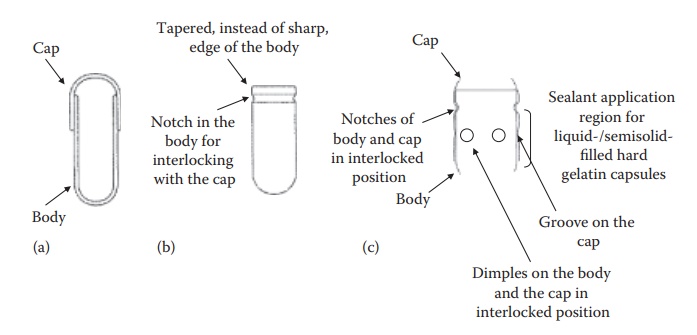

The

shapes and interlocking arrangement of the body and the cap have evolved to

meet the manufacturing and use requirements of hard gelatin capsules as shown

in Figure 21.2.

Figure 21.2 Schematic diagrams

(a–c) of hard gelatin capsules illustrating their design features. The larger,

narrower part of the capsules is the body and the smaller, wider part is the

cap.

·

Conventionally, the body and the cap had smooth edges with a

diam-eter of the cap being slightly higher than that of the body. The two

components could slide over each other (Figure 21.2a).

·

To minimize defects during the production process, the

design of the edge of the body was tapered to allow smooth penetration into the

cap with minimum defects during high-speed production operation (Figure 21.2b).

·

The capsules were modified to have an encircling groove each

on the cap and the body (Figure 21.2c) and/or a

notch to allow firm locking of the cap on the body (Figure

21.2b and c).

·

To accommodate the need for a firm seal in the case of

liquid and semisolid-filled hard gelatin capsules, raised circular bands (dimples) were introduced on the body and

the cap along the sealing zone (Figure 21.2c).

·

For the use of hard gelatin capsules in double-blind

clinical trials, it was necessary to have hard gelatin capsules that could not

be reopened after closing. To meet this objective, capsules with the cap that

covers most of the body were developed.

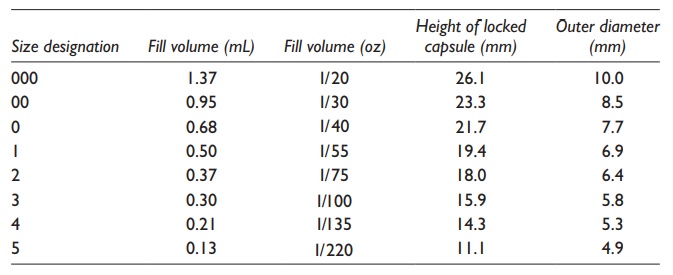

For

human use, empty gelatin capsules are manufactured in eight sizes, ranging from

000 (the largest, fill volume 1.37ml) to 5 (the smallest, fill volume 0.13ml),

as shown in Table 21.1. The powder-filling

capacity of these capsules varies depending on the packed density of the

formulation. Modern high-speed capsule-filling machines are capable of filling

up to 200,000 capsules per hour, matching the production capacity of tablets.

The formulation filled weight in the capsules can range from 30 to 1400 mg,

depending on the powder’s bulk and compact densities.

Table 21.1 Typical sizes of hard gelatin capsules

Hard

gelatin capsules can be filled with powders, granules, pellets, microtablets,

tablets, capsules, liquids, or semisolids. Most of the marketed products

contain powders or granules. Recently, the liquid- or semisolid-filled hard

gelatin capsules have gained popularity.

After

ingestion, the gelatin shell imbibes water, softens, swells, and dissolves in

the GI tract. Encapsulated drugs are released rapidly and dis-persed easily,

leading to rapid absorption.

Advantages and disadvantages of hard gelatin capsules

Comparison with tablets

Hard

gelatin capsules often provide formulation capability for uniquely challenging

drug molecules. For example, a drug candidate with a low melt-ing point or that

is liquid at room temperature usually has poor manufac-turability as a tablet,

especially if it requires a high dose. Such a compound can be encapsulated in a

liquid- or semisolid-filled hard gelatin capsule.

In

addition, very low-dose drugs (in μg) can have content uniformity

chal-lenges when formulated as a tablet. The distribution of these drugs can be

significantly better when encapsulated as a solution in a liquid or semisolid

matrix in a hard gelatin capsule.

Hard

gelatin capsules generally require less formulation components and place less

stringent requirement on the powder properties of the formula-tion. They can

also allow flexibility in formulation with the possibility of filling one or

more of diverse systems including powders, granules, pellets, and small

tablets. In addition, hard gelatin capsules can be used for blind-ing in

clinical studies.

The

disadvantages of hard gelatin capsules are owed to the inherent high moisture

content requirement of gelatin. For example, highly soluble salts, such as

iodides, bromides, and chlorides, of drugs are generally not formu-lated in

hard gelatin capsules because these can draw moisture from the shell, thus

making the shell brittle. Storage under low humidity conditions, such as with

the use of desiccant in packaging, can also make the shell brittle. In

addition, gelatin is prone to cross-linking in the presence of very low (in

parts per million range) concentrations of formaldehyde, which may be present

in certain pharmaceutical excipients such as polyethylene glycol (PEG).

Comparison with soft gelatin capsules

In

comparison to soft gelatin capsules, the manufacturing process of hard gelatin

capsules is less demanding, tedious, and costly. This is because the soft

gelatin capsule manufacture requires the formation of gelatin ribbons during

the encapsulation process itself, whereas the hard gelatin capsules use

premanufactured capsule shells. The hard gelatin capsule manufacture also does

not require a curing or moisture-loss step after encapsulation of the drug

formulation.

The

residual water in the capsule shells is lower (~10–16% w/w) for hard gelatin

capsules than for soft gelatin capsules (~30% w/w). This can affect the

stability of the encapsulated formulation directly by chemical degrada-tion (e.g.,

hydrolysis) of water-sensitive compounds or plasticization of the reaction

medium with water, thus increasing the rate of degradation. In addition, soft

gelatin capsule shells have a high oxygen permeation rate, which can contribute

to the oxidation of sensitive drugs.

Solid-filled hard gelatin capsules

Main applications

Hard

gelatin capsules are often preferred over tablets as the dosage form for

initial (Phase I and Phase IIA) clinical studies of new molecular enti-ties

(NMEs). This is because the effect of limited availability of the active

pharmaceutical ingredient (API) to conduct necessary screening for the

development of tablets. Many initial clinical studies simply use a

drug-in-capsule (DIC) product, which is the only drug manually encapsulated in

the hard gelatin or HPMC capsules.

Hard

capsules are also preferred for the comparator and blinded clinical studies.

These clinical studies require that the patient and/or the doctor should not be

able to identify the actual drug product being administered to the patient. In

these studies, two or more drug products are administered after encapsulating

them in hard gelatin capsules of the same specifications and such that the

capsules cannot be opened.

Formulation considerations

Hard

gelatin capsule-manufacturing process places a relatively less strin-gent

requirement on the powder properties of the fill formulation than tab-lets. The

important formulation considerations include the following:

1.

Flow: Adequate flow

through the hopper and into the dosing device (dosator) for reproducible filling of the capsules.

2.

Density: Reproducible

density of the powder is important for fill

weight uniformity of capsules because the dosing devices in high-speed

capsule-filling machines are filled based on the volume of the powder for a

target weight.

3.

Lubricity: Magnesium stearate

is typically added to most powder formulations.

When mixed with other particles, magnesium stea-rate coats their surface and

acts as a lubricant. Lubricants facilitate the lack of adhesion to metallic

machine parts, especially the dosing device used to form a plug in high-speed

machines, and adequate flow of the formulation. Other lubricants commonly used

are stearic acid and sodium stearyl fumarate.

4.

Compactibility: Some high-speed

capsule-filling machines form a plug

of the powder before filling into the capsule. In cases where plug formation is

required for encapsulation, some level of compactibility of the powder is

needed.

5.

Noninteraction with

capsule shell:

Lack of interaction between the drug

substance and/or formulation components with the capsule shell, either gelatin

or HPMC. This interaction could be in the form of solubilization or changing

the water content of the shell. Hygroscopic and volatile components are usually

unsuitable. The fill should not contain more than 5% w/w of water. In addition,

chemical interac-tions between the components can lead to bioavailability or

stability problems. For example, the use of PEG in drug formulation can lead to

cross-linking of gelatin on storage due to the unintended presence of

formaldehyde in PEG, which can diffuse into the shell and react with gelatin.

Similar problems have been observed due to the presence of residual peroxides

in excipients.

6.

Dose: Dose and drug

loading (i.e., %w/w of the formulation,

that is the API) influences drug

content uniformity between the capsules, the extent to which the powder

properties of the formulation are affected by the physicochemical

characteristics of the drug substance, and manufacturability of the capsule

dosage form. For example, it may be difficult to assure adequate uniformity of

the content of the API for drugs with extremely low doses (e.g., in μg), and it may not be possible to

fill a capsule of acceptable size for extremely high-dose drugs (e.g., more

than 600 mg). For intermediate doses, the percent drug loading in the

formulation can range widely. Drug properties predominantly govern the powder

properties of the formulation for high drug-loading formulations (e.g., more

than 60% w/w).

7.

Particle size,

shape, and density: Particle size and shape influence the flow, uniformity, and thus content of the active in a

formulation. A drug substance with irregular or spherical-like crystals is more

likely to flow well than the needle-shaped crystals. Drug content uniformity is

also affected by particle density, if it is significantly different than the

density of the excipients.

8.

Moisture

sorption–desorption isotherm: Moisture sorption and retention properties of the drug and

excipients, indicated by a hys-teresis in the sorption–desorption isotherm, can

affect the physical stability of gelatin during storage and the chemical

stability.

9.

Solubility and wettability: Solubility and

wettability of the drug substance

affect its dissolution characteristics. A low-solubility drug substance might

require the addition of a wetting agent (e.g., surfactant such as polysorbate

80) in the formulation.

Formulation components

The

powder formulations for encapsulation into hard gelatin capsules require a

careful consideration of the filling process requirements, such as lubricity,

compactibility, and flow. Additives present in capsule formula-tions, such as

the amount and choice of fillers, lubricant, disintegrant, and surfactant, and

the degree of plug compaction, can influence drug release from the capsule. The

functional categories of formulation components are as follows:

1. Fillers (or diluents): Active ingredient is mixed

with a sufficient vol-ume of a diluent, usually microcrystalline cellulose,

lactose, man-nitol, starch, or dicalcium phosphate, to increase the bulk of the

formulation.

2. Glidants: Glidants are

finely divided dry powders added to the formu-lation in small quantities to

improve their flow rate from the hopper and into the body of the capsule during

the filling process. Glidants, such as colloidal silicon dioxide, powdered

silica gel, starch, talc, and magnesium stearate, improve flow by

a. Reducing the roughness by filling surface irregularities.

b. Reducing attractive forces.

c. Reducing electrostatic repulsion.

The

optimal concentration of the glidant used to improve the flow of a powder

mixture is generally less than 1% w/w.

3. Lubricants: Capsule formulations

usually require a lubricant just as the

tablet formulations to reduce powder adhesion to the machine parts, especially

during plug formation. Lubricants ease the ejection of plugs by reducing the

adhesion of powder to metal surfaces and fric-tion between the sliding surfaces

in contact with the powder. The most common lubricants for capsule formulations

are hydrophobic stearates, such as magnesium stearate, calcium stearate, and

stearic acid.

4. Surfactants and

wetting agents:

Surfactants may be included in cap-sule formulations of poorly water-soluble

drugs to reduce the contact angle, increase the wettability of drug particles,

and enhance drug dissolution. The most commonly used surfactants in capsule

formula-tions are sodium lauryl sulfate and sodium docusate (sodium dioctyl

sulfosuccinate).

In

addition, a hydrophilic polymer, such as HPMC, is sometimes used as a wetting

agent in the formulations of poorly soluble drugs. Powder wettability and

dissolution rate of several drugs, such as hexo-barbital and phenytoin, were

enhanced with the inclusion of methyl-cellulose or hydroxyethylcellulose in

their capsule formulations.

5. Disintegrants: A disintegrant is

frequently included to aid rapid disin-tegration and dissolution of the

contents. Common disintegrants used in hard gelatin capsule formulations

include croscarmellose sodium, crospovidone, and sodium starch glycolate.

Controlled-release

beads and minitablets are often filled into gelatin capsules for convenient

administration of an oral controlled-release (CR) dosage form. For example, SR

antihistamines, antitussives, and analgesics are first manufactured into

extended-release (XR) micro-capsules or microspheres, and then placed inside a

gelatin capsule. Another example is enteric-coated lipase minitablets that are

placed in a gelatin capsule for more effective protection of these enzymes from

the acidic environment.

Manufacturing process

Very

small-scale and experimental filling of the hard gelatin capsules can simply be

carried out manually, that is, by removing the cap from the body of an empty

capsule shell, filling the body with a preweighed amount of API or formulation,

and attaching the cap. This can be carried out in early clinical studies by the

sponsor or by the pharmacist. Compounding by

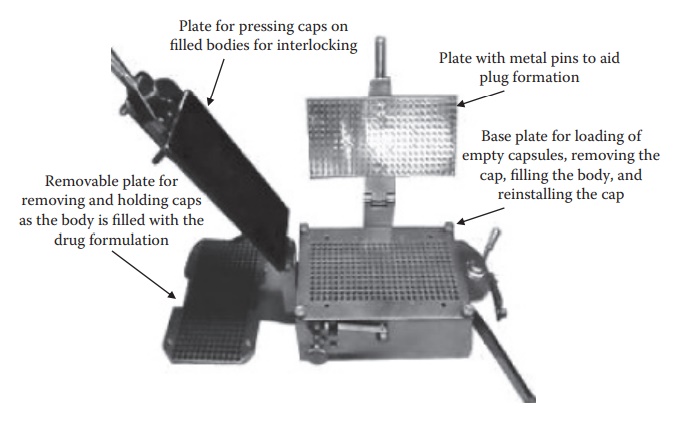

Figure 21.3 Hand-filling machine used to fill hard gelatin capsules.

the

pharmacist is preferred when the stability of the drug in the capsule is

unknown and is called on-site compounding.

Small-scale

manufacture (several hundred capsules) can be done by using a manual

capsule-filling machine. As illustrated in Figure 21.3,

the manual-filling operation involves the following steps:

1. Placing empty gelatin capsules on the removable plate

with bodies facing downward. This removable plate is then placed on the base

plate and the bodies of the capsules are locked in position with the base plate

using a lever.

2. The removable plate is removed with the caps on it. The

body is filled with the formulation manually using a plastic spetula, and the

excess powder is removed.

3. The removable plate is placed back on the base plate and

pressing the flat plate seals the capsule caps. The sealed capsules are removed

from the base plate by opening the lock on the body using the lever and inverting

the base plate.

Large-scale

filling of hard gelatin capsules follows the same principles using a high-speed

capsule-filling machine, with two significant improvements:

·

Capsule alignment and separation are driven by vacuum,

instead of mechanical interlocking.

·

Powder filling may require a soft compact (plug) formation

depend-ing on the formulation weight and capsule fill volume. This compact is

usually much softer than a typical tablet. The compaction force used for plug formation is typically 20–30 N,

compared to 10–30 kN typically used for tableting.

·

The high-speed powder filling is accomplished by either of

the two dosing devices: (a) dosator device or (b) dosing disk/tamping device.

1. The dosator device

uses an empty tube that dips into powder bed, which is maintained at a height

approximately two-fold greater than the desired length of the plug. The dosator

piston’s forward movement helps form the plug, which is then transferred to the

body of the capsule, and released.

2. The tamping device

operates by filling the cavities bored into the dosing disk, similar to the

die-filling operation during tableting. A tamping punch slightly compresses the

filled powder by repeated action, which is followed by the ejection of the plug

into the capsule body.

Liquid- and semisolid-filled hard gelatin capsules

Main applications

Liquid-

and semisolid-filled hard gelatin capsules are sometimes used to improve the

bioavailability of drug substances with low solubility and wet-tability. Lipids

in the formulation tend to increase the bile flow in vivo and promote drug absorption. For example, mixtures of

mono-, di-, and tri-glycerides of mono- or dicarboxylate esters of PEGs,

commercially available as Gelucire®, are available in various melting point and

hydrophilic–lipophilic balance (HLB) ranges. Oral availability of drug solution

in Gelucire® or in PEG is frequently higher than that of powder drug

formulation. In addition, self-emulsifying and self-microemulsifying drug

delivery systems (SEDDS and SMEDDS, respectively) can significantly improve

drug’s bioavailability, for example, in the case of cyclosporine A and

fenofibrate.

Liquid

filling of hard gelatin capsules may also be indicated in the case of drugs

with extremely low dose (e.g., in μg) and drug loading (e.g., less than

5% w/w) in the formulation to assure uniformity of content. Uniformity of drug

distribution between different dosage units can be higher with a drug solution

in a liquid or semisolid base than a blended powder.

Drugs

with manufacturability issues in a tablet dosage form may also be for-mulated

as a liquid-filled hard gelatin capsules. For example, drugs with low melting

points can show significant sticking issues in both tablet- and powder-filled

capsule dosage forms. Certain drugs with significant instability to light or

moisture can show better stability in liquid or semisolid filled, compared to a

powder-filled, hard gelatin capsule. The presence of an opaque waxy base and a

molecular mixture of the antioxidant with the drug can increase the effectiveness

of environmental protection in the capsule dosage form.

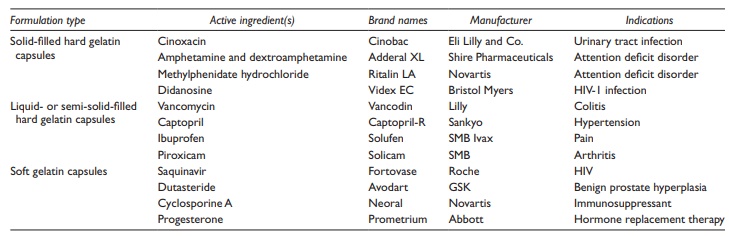

Examples

of drug substances formulated as liquid-filled hard gelatin capsules are listed

in Table 21.2.

Table 21.2 Examples of commonly used capsule dosage forms

Formulation considerations

The

main formulation considerations for liquid-filled hard gelatin capsule are

similar to those for soft gelatin capsules:

1. Noninteraction

with capsule shell: Physicochemical compatibility between the drug/formulation excipients and the capsule shell are

required for any capsule formulation. As described earlier, known drug–gelatin

interactions include pH effect on gelatin hydrolysis or tanning, hygroscopicity

or water effect on shell integrity, and the role of diffusible aldehydes in

cross-linking gelatin shell.

2. Dose: The capsule size

imposes a limit on the maximum amount of formulation

that can be filled into a hard gelatin capsule.

3. Hygroscopicity: The formulation

components should not significantly affect

the moisture level of the shell. For example, highly hygroscopic excipients

such as glycerol, sorbitol, and propylene glycol are not suit-able for

liquid-filled hard gelatin capsules in high concentrations, although they may

be used for soft gelatin capsules. This is because of the lower inherent

moisture content of the hard gelatin shell.

Formulation components

Drug

solution in an appropriate base formulation can be filled into hard gelatin

capsules at room or slightly higher temperature. The functional cat-egories of

formulation components are as follows:

1. Triglycerides for solubilization

of the drug substance. These include either

the medium chain triglycerides, such as Miglyol® 810 and 812, or the long chain

triglycerides, such as soybean oil, olive oil, and corn oil.

2. Surfactants can be included in

the formulation as solubility, dissolu-tion, and/or absorption enhancers, such

as Cremophor®, Gelucire®, Labrafil®, and Tween®.

3. Cosolvents can be used in low

concentrations, especially for SEDDS and

SMEDDS, such as ethanol, propylene glycol, and PEG.

Manufacturing process

The

main consideration and process risk in the manufacture of liquid-filled hard

gelatin capsules is their tendency to leak at the joint between the body and

the cap. This concern has been addressed in one of the two ways:

1.

Applying a zone of gelatin film on the joining region of the body and the cap.

This is known as banding, because a

band of gelatin is formed on the outside of the capsule.

2. Spraying a solution of ethanol and water on the

overlapping areas of the body and the cap along with the application of heat

(e.g., 40°C–60°C for several seconds). This process is known as sealing. The low surface tension of the

solvent mixture allows it to diffuse into and dissolve gelatin, which also

melts during heating, to allow the fusion of gelatin from the cap with that

from the body.

Related Topics