Particle shape and size - Analyses of powders

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Powders and granules

Defining particle shape and size, Defining particle size distribution, Desired particle shape and size, Factors determining particle shape, Techniques for quantifying particle shape and size, Changing particle shape and size

Particle shape and

size - Analyses of powders

Defining particle shape and size

The

size of a sphere can be defined in terms of its radius, or more com-monly,

diameter. The size of a cube can be described in terms of the length of its

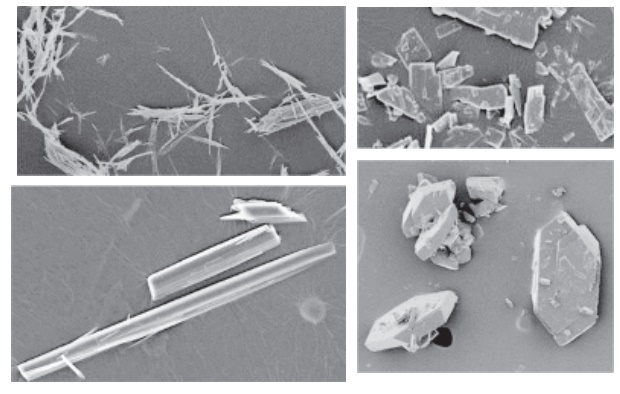

side or diagonal. However, as shown in Figure 19.1,

particles can have a diverse range of shapes from needle shape to irregular

polygo-nal. Quantitatively measuring and defining the size of these particles

can be a challenge. Nevertheless, the use of finely divided powders in

phar-maceutical unit operations requires a numerical description of particle

size, preferably as a single number, to enable comparison of different powder

types and also of different batches of the same material. Using a

one-dimensional property of a particle (such as its surface area or volume) and

describing it in terms of an equivalent sphere allow the description of a three-dimensional

object by a single number with respect to the property of interest. The

criterion of equivalency of particle size to the size of a sphere is based on

the powder’s intended use or application. For example, use of a powder for

surface catalysis or comparison of dissolution rate of different batches would

require surface area-based equivalency.

Figure 19.1 Examples of particle shapes commonly encountered for active

pharmaceutical ingredients.

Irregular-shaped

particles can be defined in terms of two parameters:

·

Diameter of an equivalent sphere. Powder processing

technologies, such as milling and granulation, tend to change the shape of

particles toward or closer to a spherical shape.

·

Aspect ratio, which is the ratio of longest to the smallest

axis of a par-ticle. It would be one for a sphere and the largest for a

needle-shaped particle. Aspect ratio helps define the deviation of a shape from

a perfect sphere.

Many

commonly used particle size measurement methods define the size of a particle

in terms of the diameter of an equivalent sphere. There are several assumptions

and/or limitations associated with this description. For exam-ple, defining

particle size in terms of the diameter of an equivalent sphere requires a consideration

of the criterion used to define equivalency.

For example, two particles can be described as equivalent in terms of volume or

surface area. Thus, size of a particle can be expressed as the diameter of a

sphere of equivalent volume or surface area of the particle being analyzed.

Defining particle size distribution

Powders

are a collection of particles of different sizes. Therefore, powders have a PSD

rather than a single particle size. A single numeric descriptor of the PSD of a

powder can be the mean particle size. The mean diameter of a set of particles

in a powder sample can be described using either arith-metic mean or geometric

mean. When using arithmetic mean diameter, the presence of fewer, larger

diameter particles can skew the calculated average result toward the large

particle size, which may not be truly representative of the batch. The

distribution of particles of a powder often follows a unimodal (one peak)

lognormal distribution (i.e., when log of particle size is plotted against the

frequency of occurrence of the particles of each size—a Gaussian or normal

distribution is obtained). Therefore, geometric mean diameter (GMD) is

generally preferred to define the particle size of a powder.

The

method for defining PSD needs to have the following properties:

·

Be independent of the statistical type of distribution in

the sample, for example, normal or lognormal.

·

Be descriptive of the particle characteristics of interest

to the intended application that is, expressing particle size as spheres of equivalent

surface area or volume depending on the application.

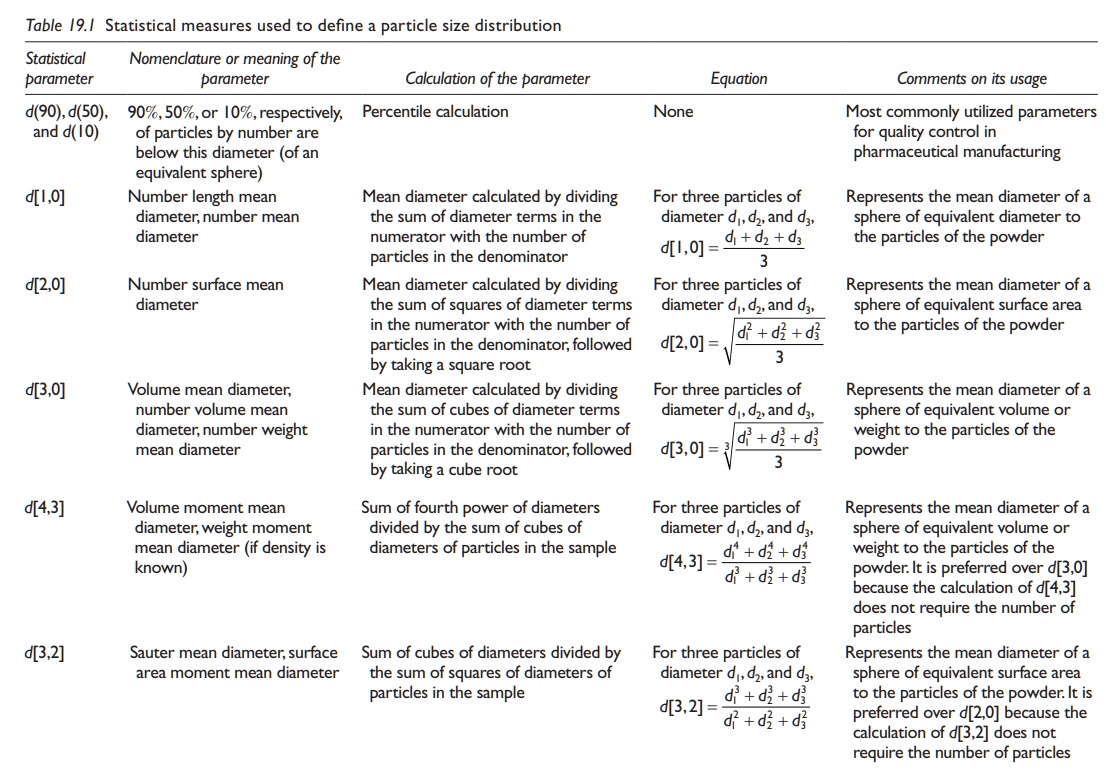

The

statistical measures listed in Table 19.1 are

frequently used to charac-terize the PSD of a powder sample.

Table 19.1 Statistical measures used to define a particle size distribution

Desired particle shape and size

The

desired particle size and shape of a powder is determined by its usage in the

downstream unit operations. For example,

·

Uniform mixing of powders is greatly facilitated if they are

of equiva-lent size by volume. Therefore, the mixing of two or more powders

with similar particle size and shape is the most likely to produce uni-form

distribution of each material in the mix.

·

Use of particles in inhalation devices requires particles to

be of simi-lar sedimentation rate in the air. Particle size expressed as

diameter of spheres with equivalent sedimentation rate in the air is called

aero-dynamic diameter.

·

The surface area per unit weight or volume (specific surface

area) of the powder determines the extent of physicochemical properties of a

material that are of surface origin. For example, for crystal pack-ing

structures that lead to the exposure of functional groups on the surface, a

polymorphic form with greater specific surface area is more likely to show

greater intensity of such surface phenomenon than another polymorphic form with

lower specific surface area. Examples of such crystal surface-dependent

physical properties include chemi-cal reactivity or surface adsorption in the

solid state and the sticking tendency of a material to the stainless steel

processing equipment dur-ing pharmaceutical manufacturing.

Notably,

the spherical shape offers the least surface area per unit volume or weight of

the material.

Factors determining particle shape

Particle

shape is primarily determined by the intrinsic properties of the material and

its manufacturing process. For example, crystal habits of a compound determine

the crystal faces exposed to the surface of the solid. Solute–solvent

interactions during crystallization determine which faces of a crystal grow

faster than others. In general, faces of the crystal that inter-act more with

the solvent grow at a slower pace than the faces that have less interaction

with the solvent. Thus, crystal shape is a function of the solvent used during

crystallization, and one can produce crystals of different shape having the

same crystalline or polymorphic form.

Particle

shape can be altered after crystallization. For example, milling of a drug

substance results in smaller, irregular-shaped crystals that are closer to the

spherical geometry. Also, pharmaceutical processes such as granula-tion,

spheronization, and spray drying can produce larger particles that are closer

to the spherical shape.

Techniques for quantifying particle shape and size

Particle

size is commonly measured using one or more of the following techniques:

·

Sieve analysis: This is a

conventional technique that involves mass

fractionation of a powder sample on a set of sieves, or wire meshes, of

defined size openings using mechanical vibration. Several sieves of increasing

size openings are placed one over another. A powder sample is loaded on the top

sieve. Mechanical vibration is applied to allow the powder to sift through as

many sieves as it would until it reaches a state where powder particles do not

move through the sieve openings any more. The amount of powder on each sieve is

weighed and expressed as the size fraction is lower than sieve open-ing

diameter above and is higher than the one below (on which the powder was

retained). Thus, sieve analysis produces a weight distribution of particles in

different sieve fractions. The sieve analy-sis data can be used to compare the

PSD of two or more samples graphically, or by using the calculated mean

particle diameter and/or the proportion of fines.

·

Laser diffraction

analysis:

Laser diffraction analysis is based on the

size dependence of scattering of incident laser light by particulates in

the sample. A powder sample is dispersed in an insoluble liquid or air and is

passed through a beam of laser light. The scattered laser light intensity is

recorded using a detector. The angle of light scattering decreases and the

intensity of scattered light increases with the increasing particle size.

Measuring the intensity of scat-tered light at a particular angle allows the

estimation of size of the particle scattering the light. Cumulative plotting of

size of all the particles in a powder sample produces a PSD of the sample.

·

Focused beam

reflectance measurement: In situ measurement

of particle or droplet size and size

distribution in dispersed systems is often carried out using focused beam

reflectance measurement (FBRM). This is an inline technique used to generate

real-time data during chemical synthesis, such as crystallization, and

phar-maceutical processing, such as granulation. A fast spinning laser beam is

focused on the sample through a quartz lens in a conical pattern. The laser

light that encounters a particle is reflected back to the lens, where a fiber

optic collects the light and passes to a detector that quantifies the

intensity. The time period between the incident and the reflected light, the

speed of the rotating lens, and the speed of laser light are used to calculate

the length of a par-ticle passing through the focus of the laser light. This is

called the chord length. Collective plot of chord length of several particles

produces a chord length distribution. Changes in the chord length distribution

during processing are used as a fingerprint of the pro-cess dynamics.

·

Microscopy: Microscopy allows

direct visual examination of powder particles.

However, it provides only a two-dimensional image of a three-dimensional

particle. Although this technique allows versatility with respect to sample

types that can be examined, the sample prepa-ration process can introduce bias

into the sample. It is a qualitative tool for most of the applications.

Automated image analysis software is frequently used when quantitation is

desired. Several commercial instruments are available that automate the process

of image collec-tion and analysis, allowing the examination of several hundreds

or thousands of particles in a sample.

·

Sedimentation: Sedimentation

involves gravity or centrifugal force-assisted separation of the dispersed

phase from the dispersion medium over time. The density difference between the

dispersed phase and the dispersion medium leads to particle separation.

Sedimentation is not a preferred method for the assessment of particle size and

size distribution. It is more commonly used for the quality assessment of

colloidal systems, such as suspensions and emulsions, functional-ity assessment

of superdisintegrants, such as croscarmellose sodium, and separation of

particles of extremely small size from the disper-sion medium.

·

Electrozone sensing: Changes in the

electrical conductance through a

small aperture with the flow of a fluid containing sus-pended particles are

used to estimate the size and number of parti-cles in the dispersion medium.

The electrical conductance changes when a particle flows through the aperture,

with the change in conductance being proportional to the size of the particle.

It is commonly used for counting biological cells and bacteria, using a coulter

counter.

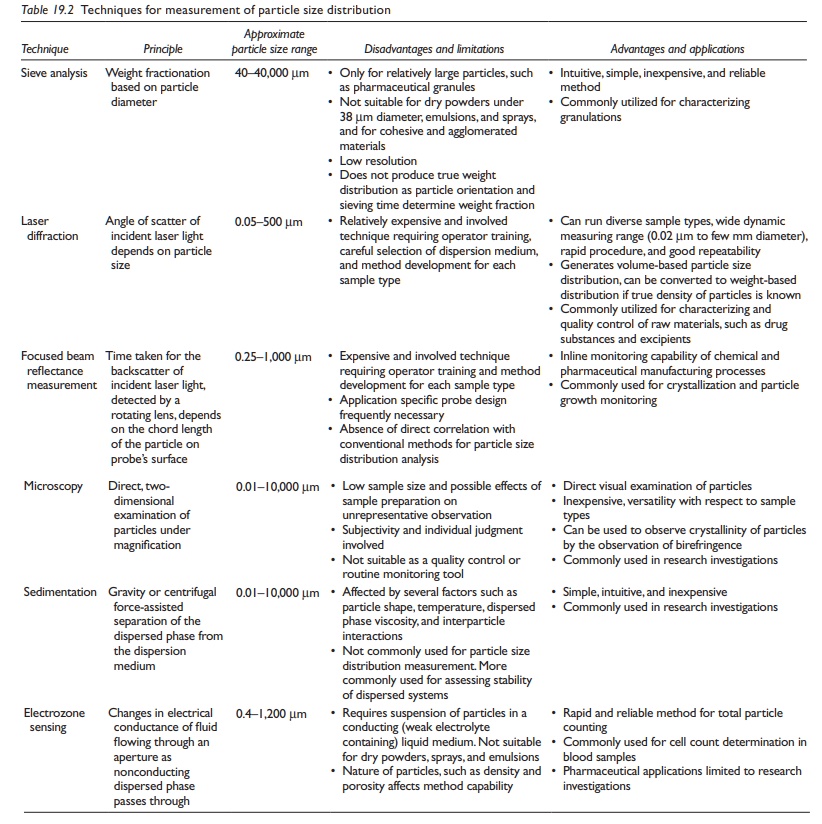

A

comparison of these techniques with respect to their merits, demerits, range of

particle size measured, and principle of operation is provided in Table 19.2.

Changing particle shape and size

Reduction

in particle size of the API is frequently desired to improve the

biopharmaceutical properties of the dosage form, such as its dissolution and

absorption. Increase in particle size of the bulk powder is generally desired

to improve its processability, such as flow properties. Particle size of the

powders can be decreased by controlled crystallization or milling (also called

comminution) of preformed particles. Particle size can be increased by

controlled agglomeration through granulation.

Table 19.2 Techniques for measurement of particle size distribution

Processing

steps to change the size of the particles invariably also results in changes in

particle shape. Milling of odd-shaped particles, such as nee-dles, tends to

reduce their aspect ratio and to change the shape toward spherical dimensions.

Granulation is often accompanied by shear force and consolidation of particles

into larger particles, which tend to have an irregular shape with low aspect

ratios. Both milling and granulation tend to increase the sphericity of

particles.

Related Topics