Pharmaceutical Process Engineering

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Introduction

Process engineering has been a central activity in pharmaceutical product development since its inception.

Introduction

Process

engineering has been a central activity in pharmaceutical product development

since its inception. The knowledge that key fundamentals and the processes to

which they are applied were in most respects equivalent to those in other

industries allowed chemical and mechanical engineering principles to be

adopted, which were thoroughly understood (McCabe et al., 1997).

The

first chapters of this book describe in some detail the important fundamentals

of fluid flow, heat and mass transfer. The intent is not to duplicate the

authority of an engineering text of which there are many to which this volume

owes tribute. Rather it is hoped that the topics are covered in sufficient

depth to allow professionals in the pharmaceutical sciences, without engineering

training, to feel comfortable when faced with matters pertaining to these

topics. The chapters immediately following the fundamentals introduce processes

that either employ the principles described earlier or that relate to important

aspects of pharmaceutical development. Hence, these might be considered methods

of handling and conveying different states of matter, that is, solids, liquids,

or gases. The heterogeneous nature of many pharmaceutical formulations leads to

a degree of empiricism in the understanding of processes and their application

to achieve the desired goals of uniform and reproducible drug delivery from the

designated dosage form or the handling of environ-mental or other conditions

related to their preparation. Consequently, the chapters dealing with solids

(including crystallization, powders, size, mixing, and blending), filtration,

sterilization, evaporation, drying, and humidity have their basis in theory but

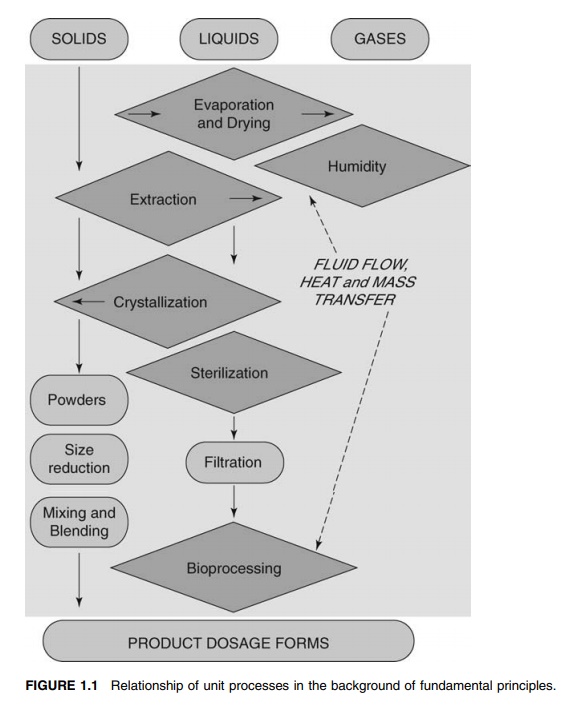

often invoke semiempirical interpretation. Figure 1.1 illustrates the relationship

between the various unit processes and the under-lying fundamental principles.

The

value of any text in pharmaceutical process engineering is that the fundamental

nature of the topics presented gives it a long shelf life since the science and

engineering have not changed significantly in decades. However, the last decade

has been characterized by changes in the common practices of conducting

experiments to rapidly and efficiently define the process accom-panied by a

change in the regulatory environment in which manufacturing is conducted.

It

may seem premature to introduce this evolving technical and regulatory

consideration into an otherwise slowly changing foundational text. However, it

appears that the important principles of statistical experimental design, risk

assessment, and quality by design, including specific tools to aid with these

approaches, are established elements of process engineering.

The

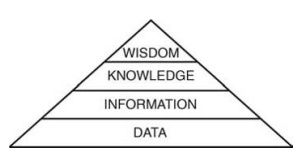

final chapters of the book relate to these topics. In the information age, the

advent of computer technology allows the collection of vast quantities of data,

which can then be manipulated in real time or near real time to promote the

quality of the product and to ultimately bring therapies to patients. The

challenge of working in this environment is to manipulate this data to fulfill

the promise shown in Figure 1.2.

FIGURE 1.1 Relationship of unit processes

in the background of fundamental principles.

FIGURE 1.2 Schematic of levels of under-standing that emanate from a comprehen-sive base of data.

The intent is to

derive from an extensive database crucial information that increases the body

of knowledge of the process or product and ultimately allows the wise

intervention to bring about a desired objective. This may seem self-evident,

but it could be argued that until relatively recently insufficient data could

be acquired to adequately elevate our understanding through the upper levels of

intelligent management. The practicalities of the experiments and their conduct

in a regulated environment may not differ dramatically from previous periods in

history, but the consideration of an operating framework and the facility to

acquire relevant data has changed substantially. This is undoubtedly an

improvement and should be embraced by all to elevate activities to a higher

level of control and prediction commensurate with a 21st century industry.

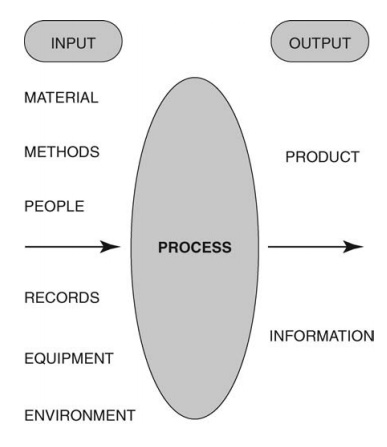

In this context, the

final chapters of the book cover in some detail the basis for statistical

experimental design, risk assessment, and supporting tools of process

analytical technology associated with quality by design. Figure 1.3 illustrates

the collation of input variables that is required to predict and control the

output for any process.

If

successful in this endeavor, the cost and efficiency of processes in the future

may be managed by informed decisions that facilitate rapid product development.

In broad terms, the following sections, therefore, consider: (i) fundamental

principles; (ii) unit processes; and (iii) experimental design, data

management, and interpretation. The intent is to begin to address process

engineering in a quality systems environment.

FIGURE 1.3 Process

input variables and their contribution to output properties.

Related Topics