Diffusion rate

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Biopharmaceutical considerations

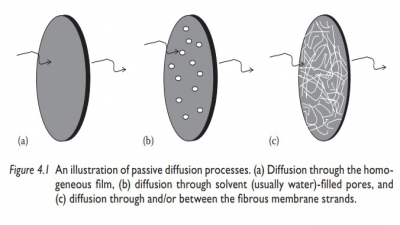

Fick’s first law of diffusion describes the diffusion process under steady state when the concentration gradient (dC/dx) does not change with time. The second law refers to a change in the concentration of diffusant with time at any distance.

Diffusion rate

Fick’s

first law of diffusion describes the diffusion process under steady state when

the concentration gradient (dC/dx) does not change with time. The second

law refers to a change in the concentration of diffusant with time at any

distance (i.e., a nonsteady state). Diffusive transport from a dosage form is

usually slow, leading to most of the drug transport happen-ing under

steady-state conditions. Therefore, it is important to understand the diffusive

conditions under a steady state.

Diffusion cell

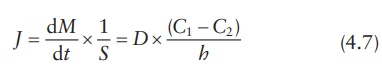

Figure 4.2 shows the schematic of a diffusion cell, with a diaphragm of thickness

h and cross-sectional area S separating the two compartments. A

concentrated solution of drug is loaded in the donor compartment and allowed to

diffuse into the solvent in the receptor compartment. The solvent in both the

compartments is continuously mixed and sampled frequently to quantitate drug

transport across the membrane.

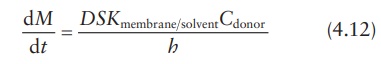

Equating

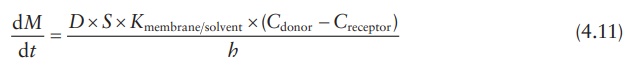

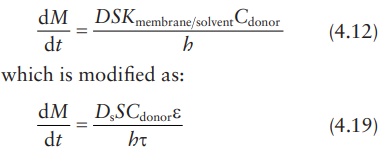

both equations for flux, Fick’s first law of diffusion may be written as:

in

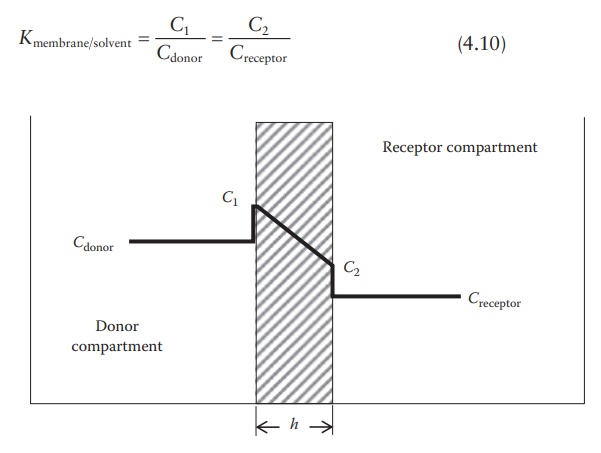

which (C1 − C2)/h approximates dC /dx. Concentrations C1 and C2 within the membrane (Figure

4.2) are determined by the partition coefficient of the solute (Kmembrane/solvent) multiplied

by the concentration in the donor com-partment (Cdonor) or in the receptor compartment (Creceptor). Thus, we have:

C1 = Cdonor × Kmembrane solvent (4.8)

and

C2 = Creceptor × Kmembrane solvent (4.9)

Therefore,

the partition coefficient is given by:

Figure 4.2 Drug concentrations in a

diffusion cell.

Hence,

Under sink conditions, the drug concentration in the receptor compart-ment is maintained much lower than the drug concentration in the donor compartment, such that Creceptor → 0. Therefore, the above equation can be simplified as:

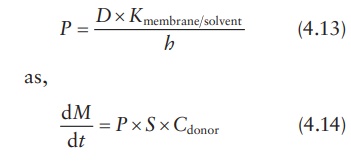

This

equation can also be expressed in terms of the permeability coeffi-cient, P, in cm/s, which is defined as:

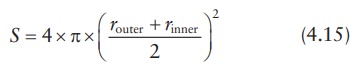

Spherical membrane-controlled drug delivery system

Following

the same principles as outlined above for a diffusion cell, dif-fusive drug

release from a spherical rate-limiting membrane enclosing a drug solution can

be defined in terms of the surface area of the membrane at the center point of

its thickness and the linear distance of drug diffusion across the membrane, x. Given the inner-boundary radius of

the membrane as rinner and

the outer-boundary radius of the membrane as router, the surface area of the sphere at its mean

radius is given by:

The

surface area of the sphere may be approximated by:

S = 4 × π × router × rinner (4.16)

And

the linear distance for solute diffusion across the membrane is given by:

x = router – rinner (4.17)

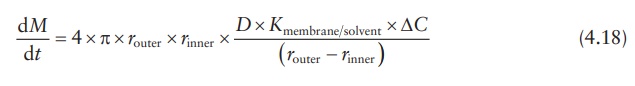

Thus,

the expression for the drug-release rate from a sphere is:

where

ΔC is the concentration gradient

between the inside and the outside of the membrane.

Thus,

permeability depends on both the properties of the diffusing solute (partition

coefficient and diffusion coefficient) and the properties of the membrane

(thickness and surface area).

Pore diffusion

In

microporous reservoir systems, drug molecules are released by diffusion through

the solvent-filled micropores. Drug transport across such porous membranes is

termed pore diffusion. In this system, the pathway of drug transport is no

longer straight but tortuous. The rate of drug transport is directly

proportional to the porosity, ε,

of the membrane and inversely pro-portional to the tortuosity, τ, of the pores. In addition, the

partition coef-ficient of the drug between the membrane and the solvent (Kmembrane solvent) is no

longer a factor, since drug dissolution in the membrane is not required.

Therefore,

In

this modified equation, Ds

is the drug diffusion coefficient in the solvent.

Determining permeability coefficient

Using

the permeability coefficient:

where,

surface area is given by:

S = 4 × π × router × rinner (4.16)

and

concentration gradient is given by ΔC = Cdonor − Creceptor, with the assumption

that Creceptor → 0 under sink conditions; thus, if ΔC ≅ Cdonor , we obtain:

Thus, the value of permeability coefficient, P, can be obtained from the slope of a linear plot of M versus t, provided that Cdonor remains relatively constant.

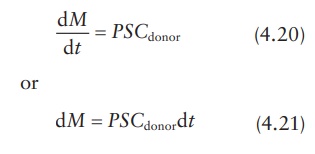

Lag time in non-steady state diffusion

sustained-release

dosage form may not exhibit a steady-state phenom-enon from the initial time of

drug release. For example, the rate of drug diffusion across a membrane slowly

increases to steady-state kinetics (Figure 4.3).

As shown in this figure, the curve is convex to the time axis in the early

stage and then becomes linear. This early stage is the nonsteady-state

condition. Later, the rate of diffusion is constant, the curve is essen-tially

linear, and the system is at a steady state. When the steady state portion of

the line is extrapolated to the time axis, the point of intersection represents

the time of zero diffusion concentration if the system had been at the steady

state all along. This time period between the actual nonsteady state and the

projected steady-state time at zero diffusion concentration is known as the lag

time. This is the time required for a penetrant to establish a uniform

concentration gradient within the membrane that separates the donor from the

receptor compartments.

Matrix (monolithic)-type non-degradable system

In

a matrix-type polymeric delivery system, the drug is distributed through-out a

polymeric matrix. The drug may be dissolved or suspended in the polymer.

Regardless of a drug’s physical state in the polymeric matrix, the

Figure 4.3 Drug diffusion rate across a

polymeric membrane.

In these systems, drug molecules can elute out

of the matrix only by dissolution in the surrounding poly-mer (if drug is

suspended) and by diffusion through the polymer structure. Initially, drug

molecules closest to the surface are released from the device. As drug release

continues, molecules must travel a greater distance to reach the exterior of

the device. This increases the diffusion time required for drug-release. This

increase in diffusion time results in a decrease in the drug-release rate from

the device with time.

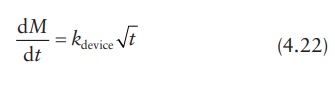

In

an insoluble matrix-type system, the drug-release rate decreases over time as a

function of the square root of time (Higuchi, 1963).

where

kdevice is a

proportionality constant dependent on the properties of the device.

This

release kinetics is observed for the release of the first 50%–60% of the total

drug content. Thereafter, the release rate usually declines expo-nentially.

Thus, the reservoir system can provide constant release with time (zero-order

release kinetics), whereas a matrix system provides decreasing release with

time (square root of time-release kinetics).

Calculation examples

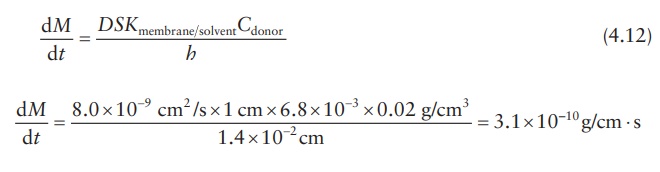

Drug-release rate

Calculation

of diffusion coefficient across and partition coefficient into a membrane

barrier of a drug delivery system is often undertaken to simulate drug-release

rate kinetics under different formulation conditions, such as drug loading. The

diffusion rate may be calculated by using experimental data in one set of

experiments. For example, if it were known that the diffusion coefficient of

tetracycline in a hydroxyethyl methacrylate–methyl methacrylate copolymer film

is D = 8.0(±4.7) × 10–9 cm2/s

and the partition coefficient, K, for

tetracycline between the membrane and the reservoir fluid of the drug delivery

device is 6.8(±5.9) × 10–3, drug-release rate can be calculated if

the design parameters of the device are known. If the mem-brane thickness, h,

of the device is 1.4 × 10–2 cm and the concentration of tetracycline

in the core, Ccore, is

0.02 g/cm3, tetracycline-release rate, dM/dt, may be calculated

as follows.

To obtain the results in micrograms per day,

dM / dt = 3 . 1× 10−10 g/cm ⋅ s × 106 µg/g × 60 × 60 × 24 s/day = 26.85 µg/day ⋅

cm

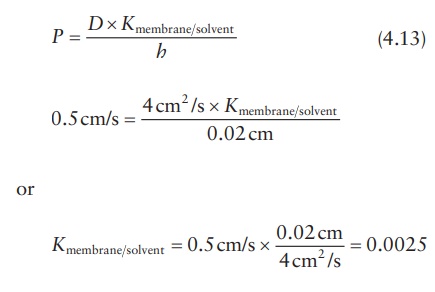

Partition coefficient

Knowing

the permeability coefficient and the diffusion coefficient of a drug in a

membrane, its partition coefficient can be calculated. For example, if a new

glaucoma drug diffuses across a barrier of 0.02 cm with a permeability

coefficient of 0.5 cm/s and the diffusion coefficient is 4 cm2/s,

its perme-ability coefficient may be calculated as follows:

Related Topics