Oral Controlled Release Systems

| Home | | Biopharmaceutics and Pharmacokinetics |Chapter: Biopharmaceutics and Pharmacokinetics : Controlled Release Medication

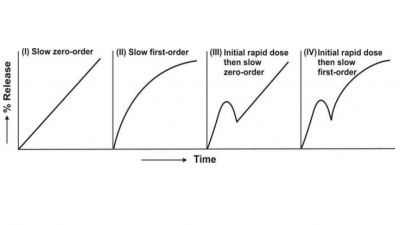

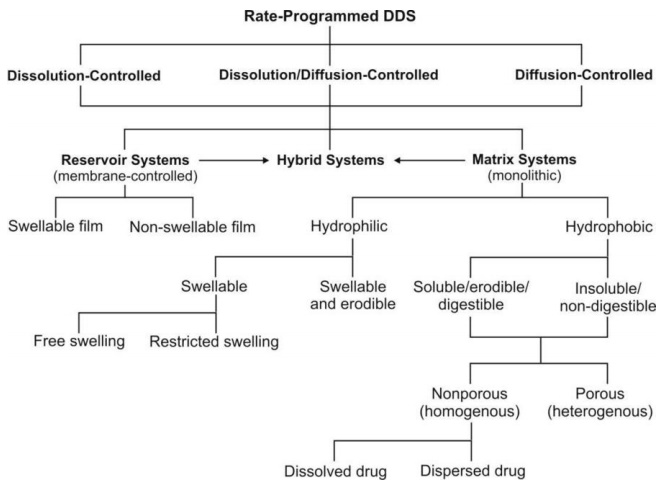

The controlled-release systems for oral use are mostly solids and based on dissolution, diffusion or a combination of both mechanisms in the control of release rate of drug. Depending upon the manner of drug release, these systems are classified as follows:

ORAL CONTROLLED RELEASE SYSTEMS

Oral route has been the most popular and

successfully used route for controlled delivery of drugs because of convenience

and ease of administration, greater flexibility in dosage form design (possible

because of versatility of GI anatomy and physiology) and ease of production and

low cost of such a system.

The controlled-release systems for oral use are

mostly solids and based on dissolution, diffusion or a combination of both

mechanisms in the control of release rate of drug. Depending upon the manner of

drug release, these systems are classified

as follows:

A. Continuous Release Systems: These

systems release the drug for a prolonged

period of time along the entire length of GIT (especially up to the

terminal region of small intestine) with normal transit of the dosage form. The

various systems under this category are:

·

Dissolution controlled release

systems

·

Diffusion controlled release

systems

·

Dissolution and diffusion

controlled release systems

·

Ion-exchange resin-drug complexes

·

Slow dissolving salts and complexes

·

pH-dependent formulations

·

Osmotic pressure controlled

systems

·

Hydrodynamic pressure controlled

systems

B. Delayed Transit and Continuous Release Systems: These systems are designed to

prolong their residence in the GIT along with their release. Often, the dosage

form is fabricated to detain in the stomach and hence the drug present therein

should be stable to gastric pH. Systems included in this category are:

·

Altered density systems

·

Mucoadhesive systems

·

Size-based systems

C. Delayed Release Systems: The

design of such systems involve release of drug only at a specific site in the GIT. The drugs contained in such a

system are those that are:

·

Destroyed in the stomach or by

intestinal enzymes

·

Known to cause gastric distress

·

Absorbed from a specific intestinal

site, or

·

Intended to exert local effect at

a specific GI site.

The two types of delayed release systems are:

·

Intestinal release systems

·

Colonic release systems

Dissolution Controlled Release Systems

Such systems are easiest to design. The drug

present in such a system may be the one:

·

With inherently slow dissolution

rate e.g. griseofulvin and digoxin; such drugs act as natural prolonged release

products

·

That produce slow dissolving

forms when it comes in contact with GI fluids e.g. ferrous sulphate, or

·

Having high aqueous solubility

and dissolution rate e.g. pentoxifylline.

Drugs belonging to the last category present

challenge in controlling their dissolution rate. The techniques employed are:

·

Embedment in slowly dissolving or

erodible matrix, and

·

Encapsulation or coating with

slowly dissolving or erodible substances (Fig. 14.6.).

Fig. 14.6 Schematic representation of dissolution controlled release systems matrix system, and (b) coated/encapsulated system

Matrix (or Monolith) Dissolution Controlled Systems

Matrix systems are also called as monoliths since the drug is

homogeneously dispersed throughout a rate-controlling medium. They are very

common and employ waxes such as beeswax, carnauba wax, hydrogenated castor oil,

etc. which control drug dissolution by controlling the rate of dissolution

fluid penetration into the matrix by altering the porosity of tablet,

decreasing its wettability or by itself getting dissolved at a slower rate. The

wax embedded drug is generally prepared by dispersing the drug in molten wax

and congealing and granulating the same. The drug release is often first-order

from such matrices.

Encapsulation/Coating Dissolution Controlled Systems (Reservoir Devices)

Here, the drug particles are coated or encapsulated

by one of the several microencapsulation techniques with slowly dissolving

materials like cellulose, PEGs, polymethacrylates, waxes, etc. The resulting

pellets may be filled as such in hard gelatin capsules (popularly called as spansules) or compressed into tablets.

The dissolution rate of coat depends upon the solubility and thickness of the

coating which may range from 1 to 200 microns.

Diffusion Controlled Release Systems

In these types of systems, the rate-controlling step

is not the dissolution rate but the diffusion of dissolved drug through a

polymeric barrier. The drug release rate is never zero-order since the

diffusional path length increases with time as the insoluble matrix is

gradually depleted of drug. The two types of diffusion controlled systems

are—matrix systems and reservoir devices.

Matrix Diffusion Controlled Systems

Here, the drug is dispersed in an insoluble matrix of rigid non-swellable hydrophobic materials or swellable hydrophilic substances. Materials used for rigid matrix are insoluble plastics such as PVC and fatty materials like stearic acid, beeswax, etc. With plastic materials, the drug is generally kneaded with the solution of PVC in an organic solvent and granulated. Waxy matrix is prepared by dispersing the drug in molten fat followed by congealing. The granules are then compressed into tablets (Fig. 14.7.a). Swellable matrix systems are popular for sustaining the release of highly water-soluble drugs. The material for such matrices are generally hydrophilic gums and may be of natural origin (guar gum, tragacanth), semisynthetic (HPMC, CMC, xanthan gum) or synthetic (polyacrylamides). The drug and the gum are granulated together with a solvent such as alcohol and compressed into tablets. The release of drug from such initially dehydrated hydrogels involves simultaneous absorption of water (resulting in hydration, gelling and swelling of gum) and desorption of drug via a swelling controlled diffusion mechanism. As the gum swells and the drug diffuses out of it, the swollen mass, devoid of drug appears transparent or glasslike and therefore the system is sometimes called as glassy hydrogel (Fig. 14.7b).

Rate Controlling Step :

Diffusion of dissolved drug through the matrix

Fig. 14.7 Diffusion controlled devices—(a) rigid matrix, and (b) swellable matrix

The drug release follows Fickian

first-order diffusion under equilibrium conditions. However, during the

swelling process, such an equilibrium may not exist and the diffusion may be

non-Fickian or anomalous diffusion.

Reservoir Devices (or Laminated Matrix Devices)

These systems are hollow containing an inner core of drug surrounded in a water insoluble polymer membrane. The polymer can be applied by coating or microencapsulation techniques. The drug release mechanism across the membrane involves its partitioning into the membrane with subsequent release into the surrounding fluid by diffusion (Fig. 14.8). The polymers commonly used in such devices are HPC, ethyl cellulose and polyvinyl acetate. A disadvantage of all such microencapsulated drug release systems is a chance of sudden drug dumping which is not common with matrix devices.

Rate Controlling Factors:

Polymeric content in coating,

Thickness of coating,

Hardness of microcapsule

Fig. 14.8 Drug release by diffusion across the insoluble membrane of reservoir

device

Dissolution and Diffusion Controlled Release Systems

In such systems, the drug core is encased in a

partially soluble membrane. Pores are thus created due to dissolution of parts

of the membrane which:

·

Permit entry of aqueous medium

into the core and hence drug dissolution, and

·

Allow diffusion of dissolved drug

out of the system (Fig. 14.9).

An example of obtaining such a coating is using a

mixture of ethyl cellulose with PVP or methyl cellulose; the latter dissolves

in water and creates pores in the insoluble ethyl cellulose membrane.

Rate Controlling Factor : Fraction

of soluble polymer in the coat

Fig. 14.9 Dissolution and diffusion controlled release system

Ion-Exchange Resin-Drug Complexes

Controlled delivery of ionisable acidic and basic

drugs can be obtained by complexing them with insoluble nontoxic anion exchange

and cation exchange resins respectively. The drug is released slowly by

diffusion through the resin particle structure. The following equation

represents the release of a basic drug, NH2R', from a cation

exchange resin RSO3H when in contact with GI fluid containing an

ionic compound A+B- (either gastric HCl or intestinal

NaCl):

RSO3–NH3+R'

+ A+B– → RSO3-A+ + NH3+R'B–

A number of basic drugs like noscapine,

phenylpropanolamine and phentermine have been retarded by such an approach. The

complex can be prepared by incubating the drug-resin solution or passing the

drug solution through a column containing ion-exchange resin. The drug-resin

complex can be coated with cellulose or hard paraffin and formulated as ion

free suspension for paediatric use.

Slow Dissolving Salts and Complexes

Salts or complexes of drugs which are slowly

soluble in the GI fluids can be used for controlled-release of the active

principle. Amine drugs can be reacted with tannic acid to form poorly soluble

complexes that can be formulated as long acting tablets. Penicillin G has been

complexed with N,N’-dibenzyl ethylenediamine to give benzathine penicillin G

that can be formulated as oral suspension. Such complexes can be obtained by

simple acid-base reaction on mixing together solutions of individual compounds.

pH-Independent Formulations

Such systems are designed to eliminate the influence

of changing GI pH on dissolution and absorption of drugs by formulating them

with sufficient amount of buffering agents (salts of phosphoric, citric or

tartaric acids) that adjust the pH to the desired value as the dosage form

passes along the GIT and permit drug dissolution and release at a constant rate

independent of GI pH. The dosage form containing drug and buffer is coated with

a permeable substance that allows entry of aqueous medium but prevents

dispersion of tablet.

Osmotic Pressure Controlled Systems

Unlike the solution-diffusion mechanism for most systems, an oral osmotic pump, popularly called as oros, works on the principle of osmotic pressure to release the drug at a constant zero-order rate. A core comprising of drug and an osmotically active substance (also called as osmogen) such as potassium chloride or mannitol is surrounded by a rigid semipermeable membrane coating such as cellulose ester or cellulose ether having an orifice of 0.4 mm diameter produced by laser beam for drug exit. When exposed to GI fluids, water flows through the semipermeable membrane into the tablet due to osmotic pressure difference which dissolves the drug and pumps it out through the orifice by the osmotic force (Fig. 14.10). Such devices can be used to target specific areas of the GIT.

Rate Controlling Factors :

Orifice diameter

Membrane area

Membrane thickness

Membrane permeability

Osmotic properties of the core

Drug solubility

Fig. 14.10 Oral osmotic pump (oros)

The oros principle can be used to design multiunit dosage forms consisting of

drug core particles coated with a water permeable membrane in which the

delivery orifice is made by using a channelling agent such as PVP and the

coated particles filled in a capsule.

Hydrodynamic Pressure Controlled Systems

The hydrodynamic pressure generated by swelling of a hydrophilic gum can also be used to activate the delivery of drugs. The device comprises of a rigid, shape retaining housing enclosing a collapsible, impermeable compartment containing liquid drug (Fig. 14.11). The space between the external housing and the drug compartment contains a layer of swellable, hydrophilic gum such as polyhydroxyalkyl methacrylate. In the GIT, the gum imbibes water through the opening present at the lower side of external housing and swells creating a hydrodynamic pressure. The pressure thus created squeezes the collapsible drug reservoir to release the medicament through the delivery orifice at a zero-order rate. Such systems are also called as push-pull osmotic pumps.

Rate Controlling Factors :

Fluid permeability

Surface area of wall with openings

Hydrodynamic pressure gradient

Fig. 14.11 Hydrodynamic pressure controlled

system (push-pull osmotic pump)

Altered Density Systems

The transit time of GI contents is usually less

than 24 hours. This is the major limiting factor in the design of oral

controlled-release formulations which can reduce the frequency of dosing to a

time period little more than the residence time of drug. However, if the

residence time of drug in the stomach and/or intestine is prolonged in some

way, the frequency of dosing can be further reduced. There are 3 ways by which

this can be achieved—altering the density of drug particles, use of mucoadhesive

polymers and altering the size of the dosage form. The altered density approach

involves use of either high or low density pellets.

High Density Pellets

The density of GI fluids is around 1.4 g/cc. Use of

drug pellets having density greater than this value, preferably above 1.6 g/cc,

results in prolonged GI residence that is unaffected by food. Iron oxide,

titanium dioxide and barium sulfate have been used to increase the density of

drug pellets. The drug is coated on the heavy core and then covered by a diffusion

controlled membrane (Fig. 14.12a).

Low Density Pellets

Also called as hydrodynamically

balanced systems, such pellets, having density less than that of GI fluids,

float on the gastric juice for an extended period of time while slowly

releasing the drug. Globular shells such as that of poprice and celluloses have

been used to lower the density of system (Fig. 14.12b). A swellable gum like HPMC can be used for a similar purpose

(Fig. 14.12c).

Fig. 14.12 Altered density systems

Floating or buoyant tablets/capsules can be

formulated by granulating a drug with 20

to 80% of hydrogel such as HPMC, HEC and HPC. On contact with GI fluids, the

tablet swells and forms a diffusible gel barrier that lowers the density of

system to less than 1 allowing it to float. Lipophilic polymers such as

silicone elastomer can also be modified to have swelling properties. This is

achieved by impregnating a water miscible liquid such as glycerol or a

water-soluble salt such as sodium chloride in the lipophilic matrix. On contact

with aqueous medium, the modified lipophilic polymer swells due to absorption

of water by the hydrophilic additives in the matrix. Alternatively, a gas

filled flotation chamber can be attached to a membrane coated tablet for making

it buoyant.

Mucoadhesive Systems

A bioadhesive polymer such as cross-linked

polyacrylic acid, when incorporated in a tablet, allows it to adhere to the

gastric mucosa or epithelium. Such a system continuously releases a fraction of

drug into the intestine over prolonged periods of time.

Size-Based Systems

Gastric emptying of a dosage form can be delayed in

the fed state if its size is greater than 2 mm. Dosage form of size 2.5 cm or

larger is often required to delay emptying long enough to allow once daily

dosing. Such forms are however difficult to swallow.

Intestinal Release Systems

A drug may be enteric coated for intestinal release

for several known reasons such as to prevent gastric irritation, prevent

destabilization in gastric pH, etc. Certain drugs are delivered to the distal

end of small intestine for absorption via Peyer’s patches or lymphatic system. Peyer’s patches are mucosal lymphoid

tissues that are known to absorb macromolecules like proteins and peptides and

antigens by endocytosis. Selective release of such agents to Peyer’s patch

region prevents them from getting destroyed/digested by the intestinal enzymes.

Such a site can be utilized for oral delivery of insulin. Lymphatic system on the other hand is known to absorb highly

lipophilic agents directly into the systemic circulation without their

first-pass through liver. The drug is absorbed by two mechanisms—chylomicrons

which are fatty vesicles that entrap hydrophobic drugs, and pinocytic uptake of

macromolecules.

Colonic Release Systems

Drugs are poorly absorbed through colon but may be

delivered to such a site for two reasons—

a. Local action as in the

treatment of ulcerative colitis with mesalamine, and

b. Systemic absorption of protein

and peptide drugs like insulin and vasopressin.

Advantage is taken of the fact that pH-sensitive

bioerodible polymers like polymethacrylates release the medicament only at the

alkaline pH of colon or use of divinylbenzene cross-linked polymers that can be

cleaved only by the azoreductase of colonic bacteria to release free drug for

local effect or systemic absorption.

Related Topics