Pharmacokinetic Principles in the Design and Fabrication of Controlled-Release Drug Delivery Systems

| Home | | Biopharmaceutics and Pharmacokinetics |Chapter: Biopharmaceutics and Pharmacokinetics : Controlled Release Medication

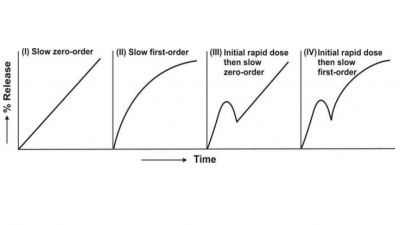

The controlled-release dosage forms are so designed that they release the medicament over a prolonged period of time usually longer than the typical dosing interval for a conventional formulation.

PHARMACOKINETIC PRINCIPLES IN THE DESIGN AND FABRICATION OF

CONTROLLED-RELEASE DRUG DELIVERY SYSTEMS

The controlled-release dosage forms are so designed

that they release the medicament over a prolonged period of time usually longer

than the typical dosing interval for a conventional formulation. The drug

release rate should be so monitored that a steady plasma concentration is

attained by reducing the ratio Css,max/C ss,min while

maintaining the drug levels within the therapeutic window. The rate-controlling

step in the drug input should be determined not by the absorption rate but by

the rate of release from the formulation which ideally should be slower than

the rate of absorption. In most cases, the release rate is so slow that if the

drug exhibits two-compartment kinetics with delayed distribution under normal

circumstances, it will be slower than the rate of distribution and one can,

thus, collapse the plasma

concentration-time profile in such instances into a one-compartment model i.e. a one-compartment model is suitable and applicable for the design of

controlled-release drug delivery systems. Assuming that the KADME of a drug are first-order

processes, to achieve a steady, non-fluctuating plasma concentration, the rate

of release and hence rate of input of drug from the controlled-release dosage

form should be identical to that from constant rate intravenous infusion. In

other words, the rate of drug release from such a system should ideally be

zero-order or near zero-order. One can thus treat the desired release rate Ro

of controlled drug delivery system according to constant rate i.v. infusion. In

order to maintain the desired steady-state concentration Css, the

rate of drug input, which is zero-order release rate (Ro), must be

equal to the rate of output (assumed to be first-order elimination process).

Thus:

R0 = Routput (14.1)

The rate of drug output is given as the product of

maintenance dose DM and first-order elimination rate constant KE.

Routput = DMKE (14.2)

For a zero-order constant rate infusion, the rate

of output is also given as:

Routput = KE Css Vd

(14.3)

Since ClT = KE Vd,

the above equation can also be written as:

Routput = CssClT (14.4a)

Or R0 = Css ClT (14.4b)

The bioavailability of a drug from controlled-release

dosage form cannot be 100% as the total release may not be 100% and the drug

may also undergo presystemic metabolism. Hence, if F is the fraction

bioavailable, then:

Substituting equation 14.6 in equation 14.5 and rearranging, we get:

where τ = dosing interval.

From the above equation, one can calculate the dose

of drug that must be released in a given period of time in order to achieve the

desired target steady-state concentration. It also shows that total systemic

clearance is an important parameter in such a computation.

Since attainment of steady-state levels with a

zero-order controlled drug release system would require a time period of about

5 biological half-lives, an immediate-release dose, DI, called as loading

dose, may be incorporated in such a system in addition to the

controlled-release components. The total dose, DT needed to maintain

therapeutic concentration in the body would

then be:

DT = DI + DM (14.8)

The immediate-release dose is meant to provide the

desired steady-state rapidly and can be calculated by equation:

The above equation ignores the possible additive

effect from the immediate and controlled-release components. For many

controlled-release products, there is no built-in loading dose.

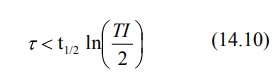

The dosing interval for a drug following

one-compartment kinetics with linear disposition is related to elimination

half-life and therapeutic index TI according to equation:

Related Topics