Devices for pulmonary drug delivery

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Organ-specific drug delivery

Pulmonary drug delivery almost invariably requires aerosolization of the drug using a device or mechanism that can achieve controlled drug particle formation and delivery.

Devices for

pulmonary drug delivery

Pulmonary

drug delivery almost invariably requires aerosolization of the drug using a device

or mechanism that can achieve controlled drug particle formation and delivery.

Examples of devices that have been used for pulmo-nary delivery include the

following:

1. Metered dose

inhaler:

Pressurized spray is a metered dose inhaler (MDI) that incorporates propellant(s), surfactant(s), and the drug in

either dis-solved or suspended state in its formulation. Pressurized metered

dose inhalers provide constant pressure on the liquid formulation and

con-sistent quantity of drug release on actuation of the valve. The

propel-lants used in these formulations include chlorofluorocarbons (CFCs) and

hydrofluoroalkanes (HFAs). Effective use of an MDI requires patient

coordination of breathing and actuation to provide maximum amount and flow

velocity of air going into the lungs. Drug solubility, vapor pressure, surface

tension, solubility of oxygen/hygroscopicity, and density affect the

effectiveness of drug delivery through the MDIs. MDIs are commonly used for the

delivery of drugs for asthma and chronic obstructive pulmonary diseases (COPD).

2. Nebulizer: The nebulizer uses

an air compressor as a power source instead

of a liquid propellant. Compressed air is brought in contact with an aqueous

solution of the drug in a device. Liquid shearing leads to the formation of

drug droplets that get inhaled by the patient. Droplet size is a key factor in

effective pulmonary delivery of the drug through this route. The droplet size

is typically controlled through the orifice diameter of the baffle, pressure of

the gas, and the density, con-centration, viscosity, surface tension, and flow

rate of the drug solu-tion. Nebulizers are frequently used in applications

where patient’s strong inhalation is not required for effective drug delivery

such as in pediatric or hospitalized patients.

3. Dry powder

inhaler:

The dry powder inhaler (DPI) allows the drug to be formulated in dry state, in which it may be more stable, does

not require the use of a liquid propellant, and also does not require patient

coordination between breathing and actuation. DPIs consist of a sus-pension of

fine particulate drug formulation, which is dispersed by mechanical, pneumatic,

or electrical energy, or by the strength of the vacuum generated by the

patient’s breathing. DPIs have been used to treat diseases such as asthma,

bronchitis, emphysema, and COPD.

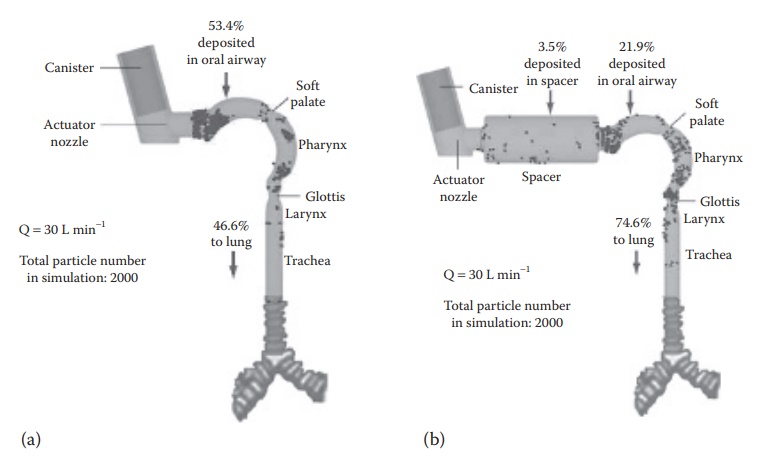

Optimization

of particle properties and device parameters can increase drug penetration to

the lungs. For example, simulation results of hydroflu-oroalkane

(HFA)-propelled metered dose inhaler (pMDI) show increased droplet transport

and deposition to the lungs when used with a spacer (Figure

15.1). This study illustrates the impact of a simple spacer in terms of

enhanced droplet percentage reaching the tracheobronchial tree.

For

further discussion and details on the devices used for pulmonary drug delivery,

see Chapter 24.

Figure 15.1 Drug delivery to the lung. Role of device in enhanced drug penetration

into the lung. Simulation results of hydrofluoroalkane (HFA)-propelled metered

dose inhaler (pMDI) droplet transport and deposition: (a) without and (b) with

spacer, illustrating the impact of a simple spacer in terms of enhanced droplet

percentage reaching the tracheobronchial tree. Q = Airflow Rate. (Courtesy of

Annual Reviews, Palo Alto, CA.)

Related Topics